Axial water pressure plunger pump with easy maintenance

A hydraulic column and axial technology, which is applied to the components, pumps, multi-cylinder pumps, etc. of the pumping device for elastic fluids, can solve the problems of serious friction loss and difficult replacement of seals, and achieves alleviation of vibration impact, The effect of reducing friction and wear and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

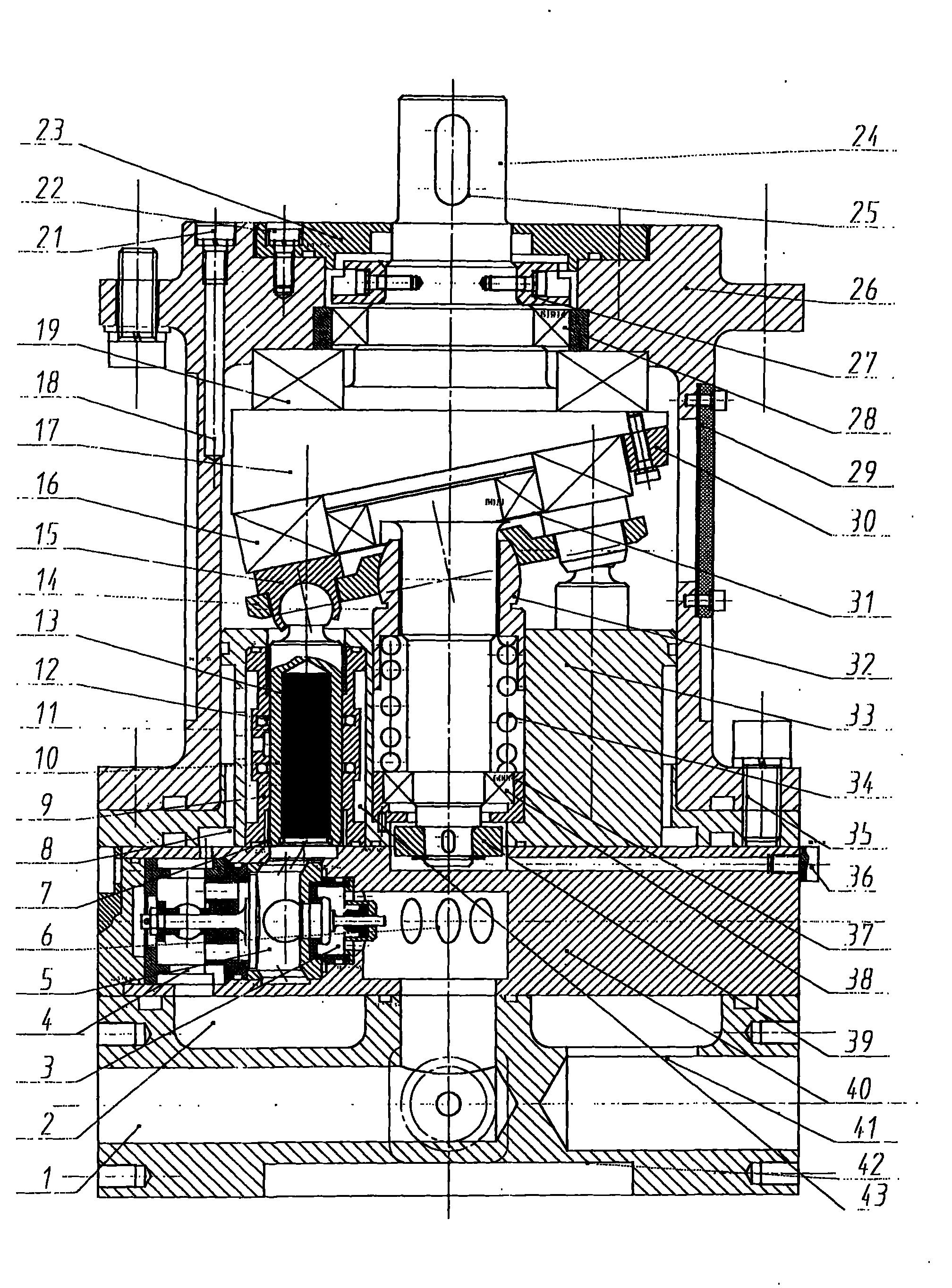

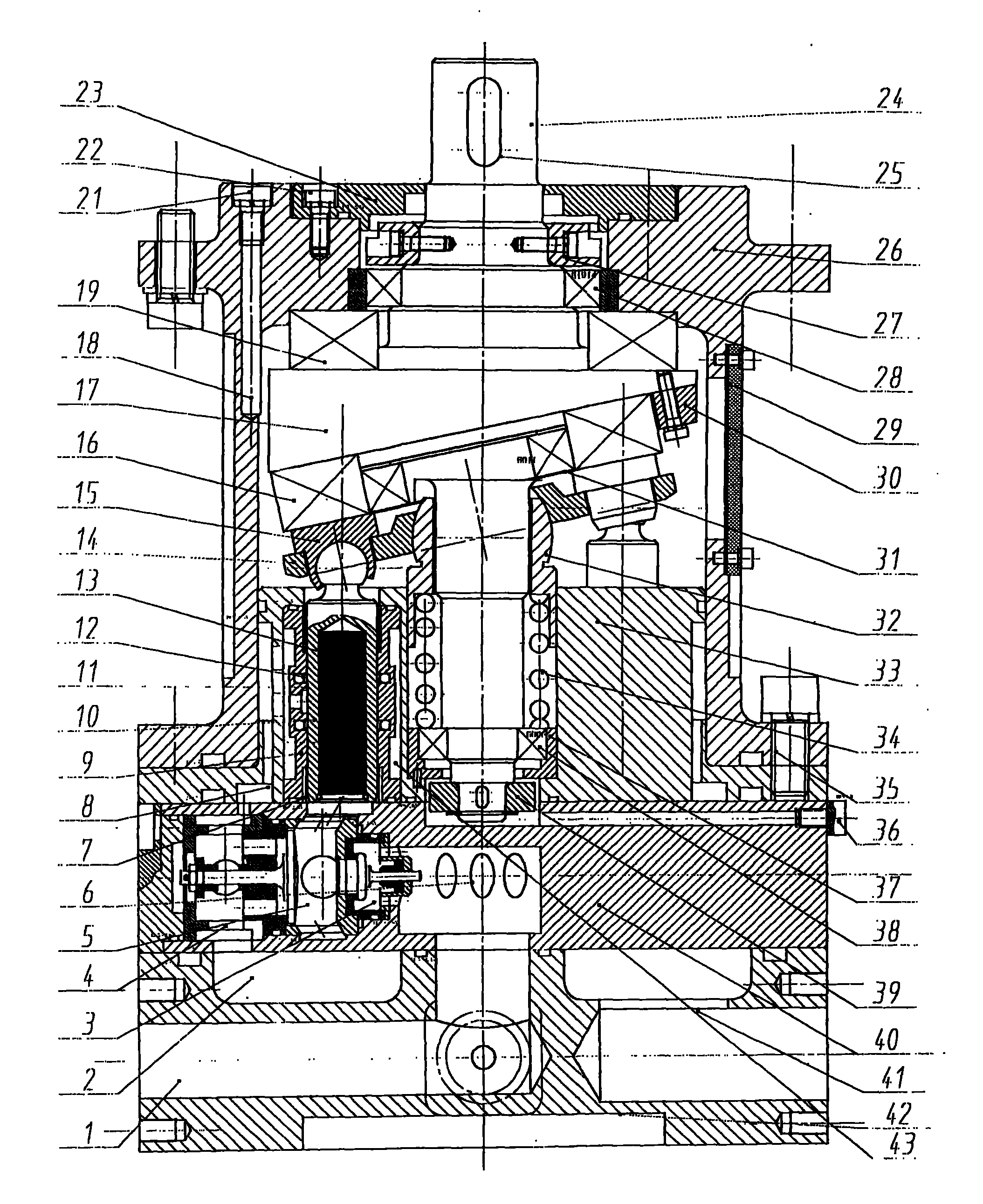

[0022] The present invention is described in detail below in conjunction with accompanying drawing example:

[0023] In the pump body 26 of the present invention, the spindle disc and the cylinder body 33 are arranged, and the corresponding distribution valve seat 40 is separated from the distribution valve seat 40 below the cylinder body 33, and the pump body 26 is connected with the distribution valve seat 40 with screws 35 to facilitate Disassembly during maintenance. The main shaft 24 and the swash plate 17 are processed into one body, collectively referred to as the main shaft disc. The upper part of the main shaft disc is positioned in the pump body 26 through the deep groove ball bearings 28 and 38 at both ends of the main shaft 24, and the lower part of the pump body 26 is provided with a bearing seat 37 which is connected with the cylinder body 33 and cooperates with the deep groove ball bearing 38, and the main shaft disc is also It is fixed in the pump body 26 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com