Axial plunger pump cylinder body

A technology for axial piston pumps and cylinders, applied in the field of high-pressure and high-power axial piston pumps, can solve the problems of large system failure and hydraulic pump scrapping, and achieve the effects of low cost, improved reliability, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

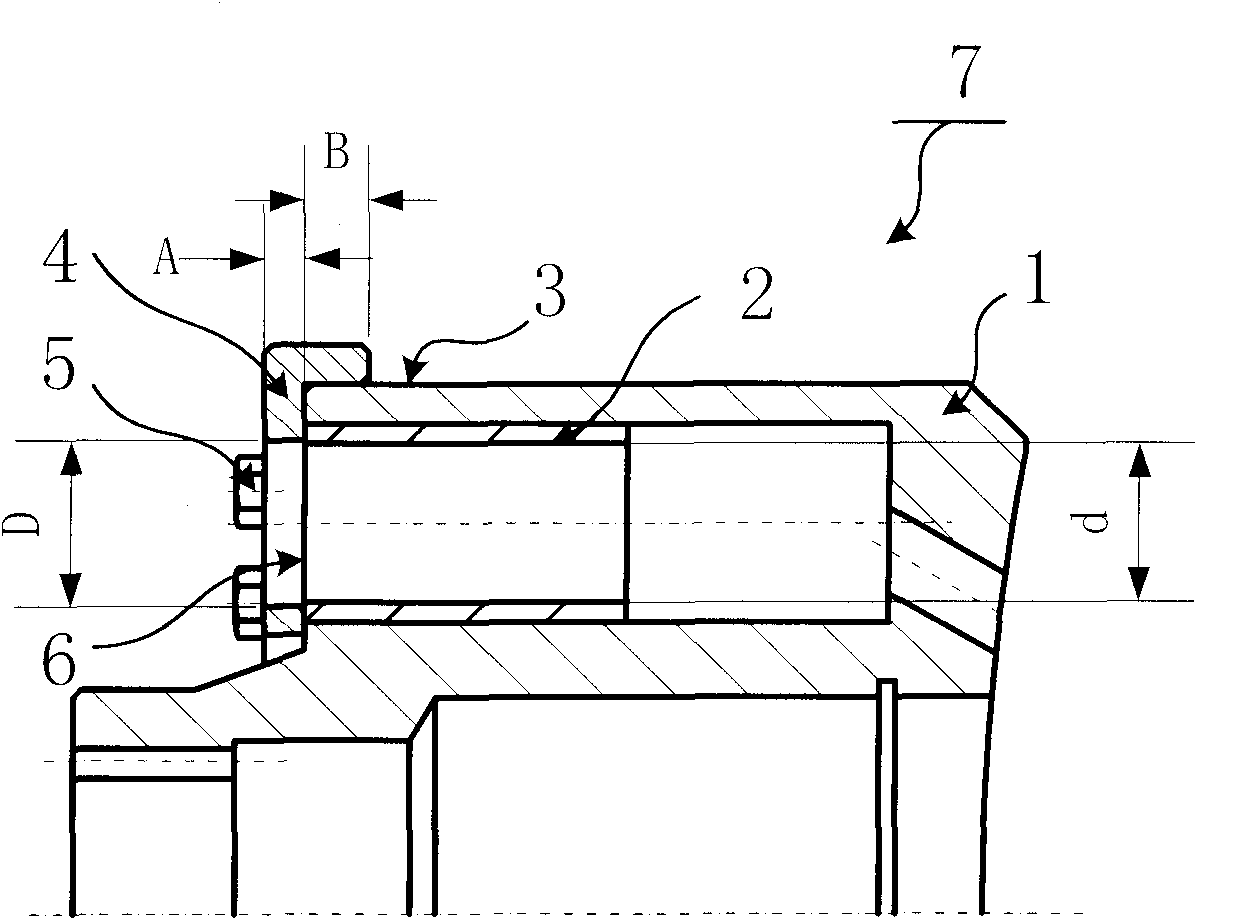

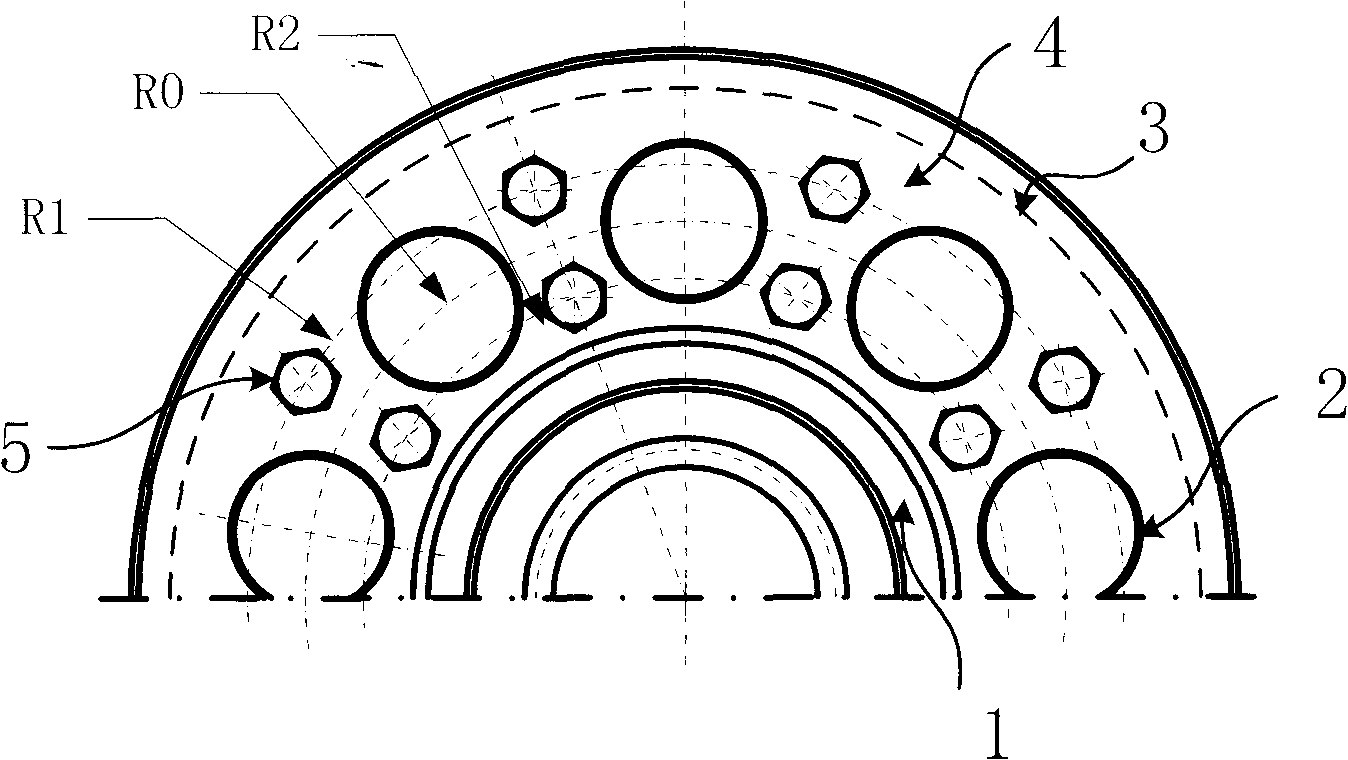

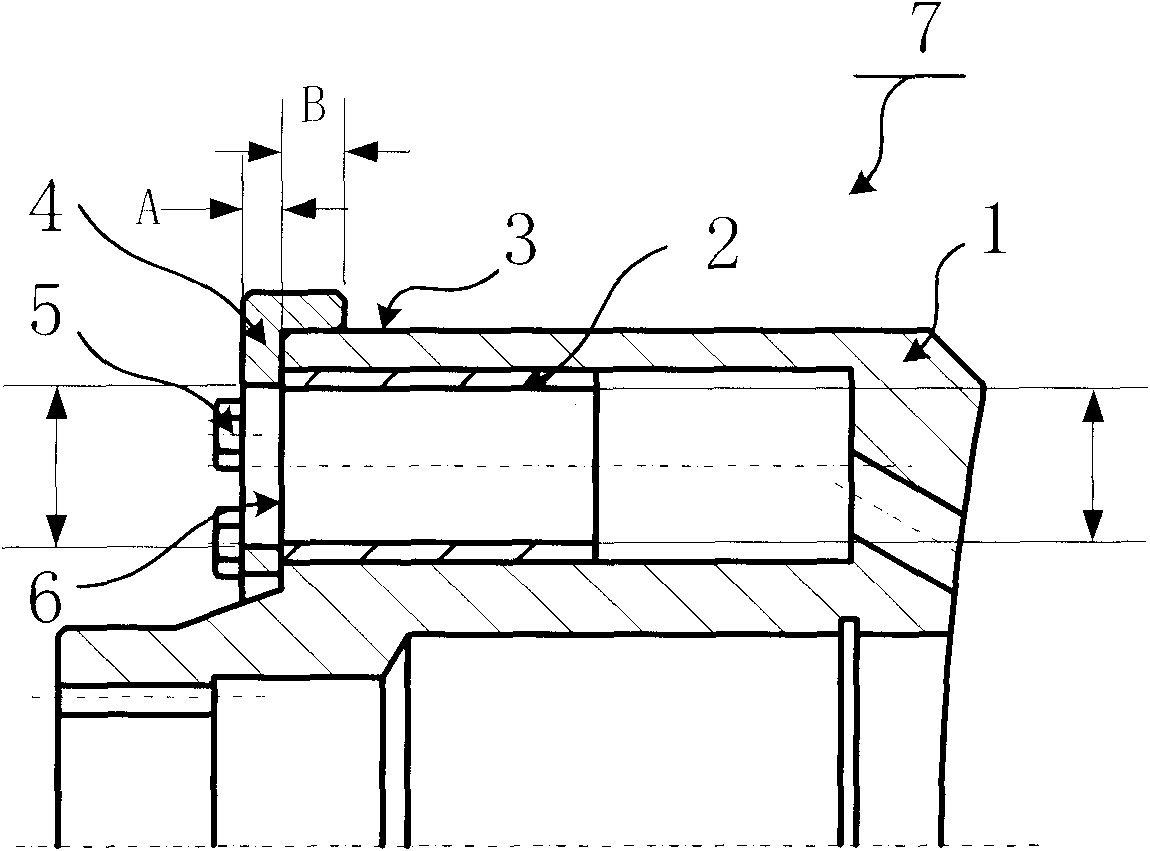

[0013] Axial piston pump cylinder reference of the present invention figure 1 . Bolt holes are opened on the base body 1 of the cylinder body to improve the machining accuracy of the outer circular surface 3 and the end face 6 of the base body 1 of the cylinder body respectively, and become the installation and positioning reference of the baffle plate 4 . The baffle plate 4 is fixed on the base body of the cylinder block by bolts. The baffle plate 4 has a certain thickness to ensure sufficient rigidity and strength. The positions corresponding to the baffle plate and the cylinder bore are opened with holes respectively, and are fixed on the cylinder body by bolts 5 .

[0014] In order to make the axial piston pump cylinder meet different use requirements under different working conditions, the size of the axial piston pump cylinder has the following requirements: the diameter D of the baffle hole of the axial piston pump cylinder is larger than the cylinder hole The diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com