Contact indicating method based on insulated measuring unit pair on surface of measured object

A technology for measuring units and object surfaces, which is applied in the field of high-precision measurement of large diameters, and can solve problems such as large measurement errors, increased measurement time, and reduced measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

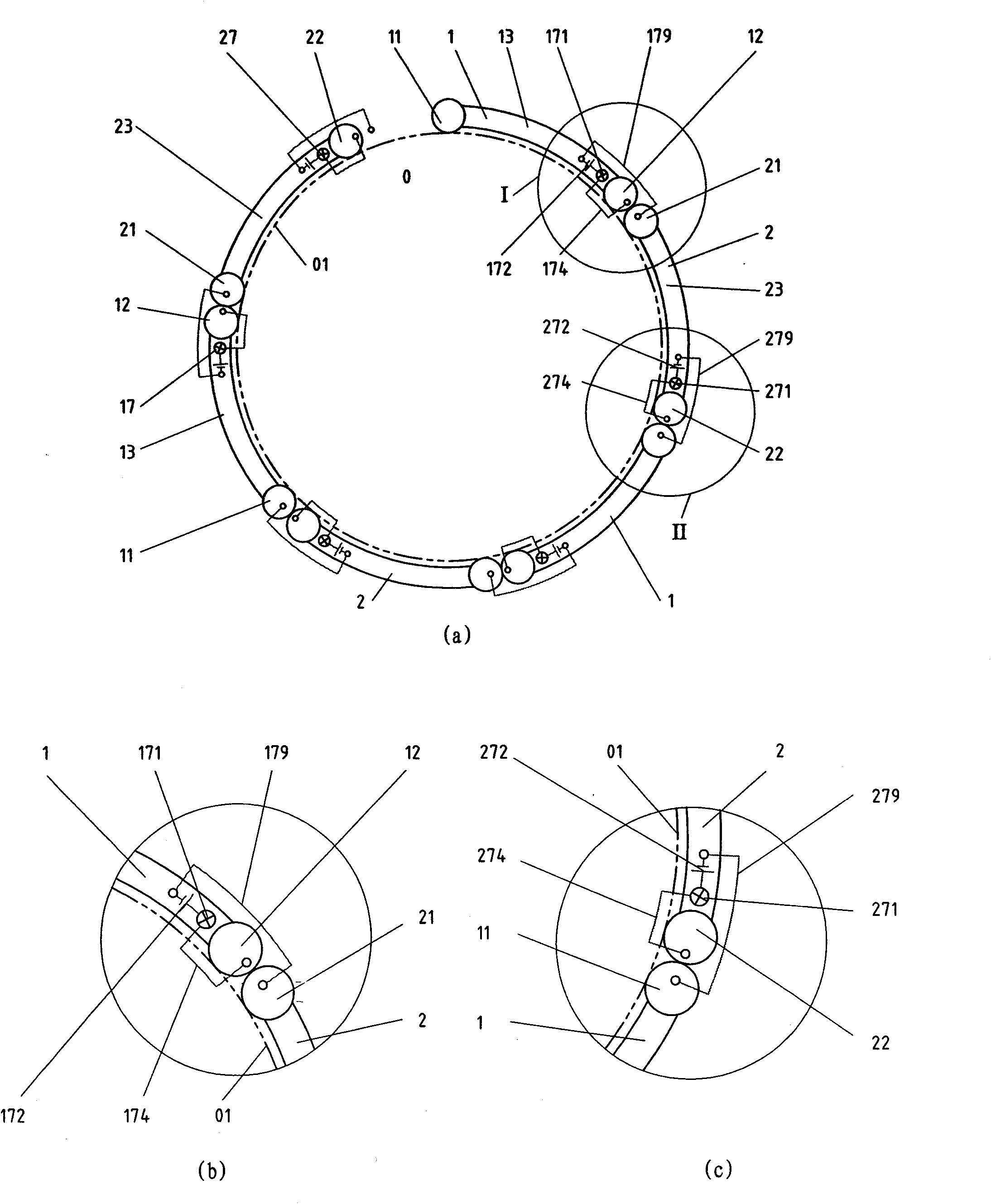

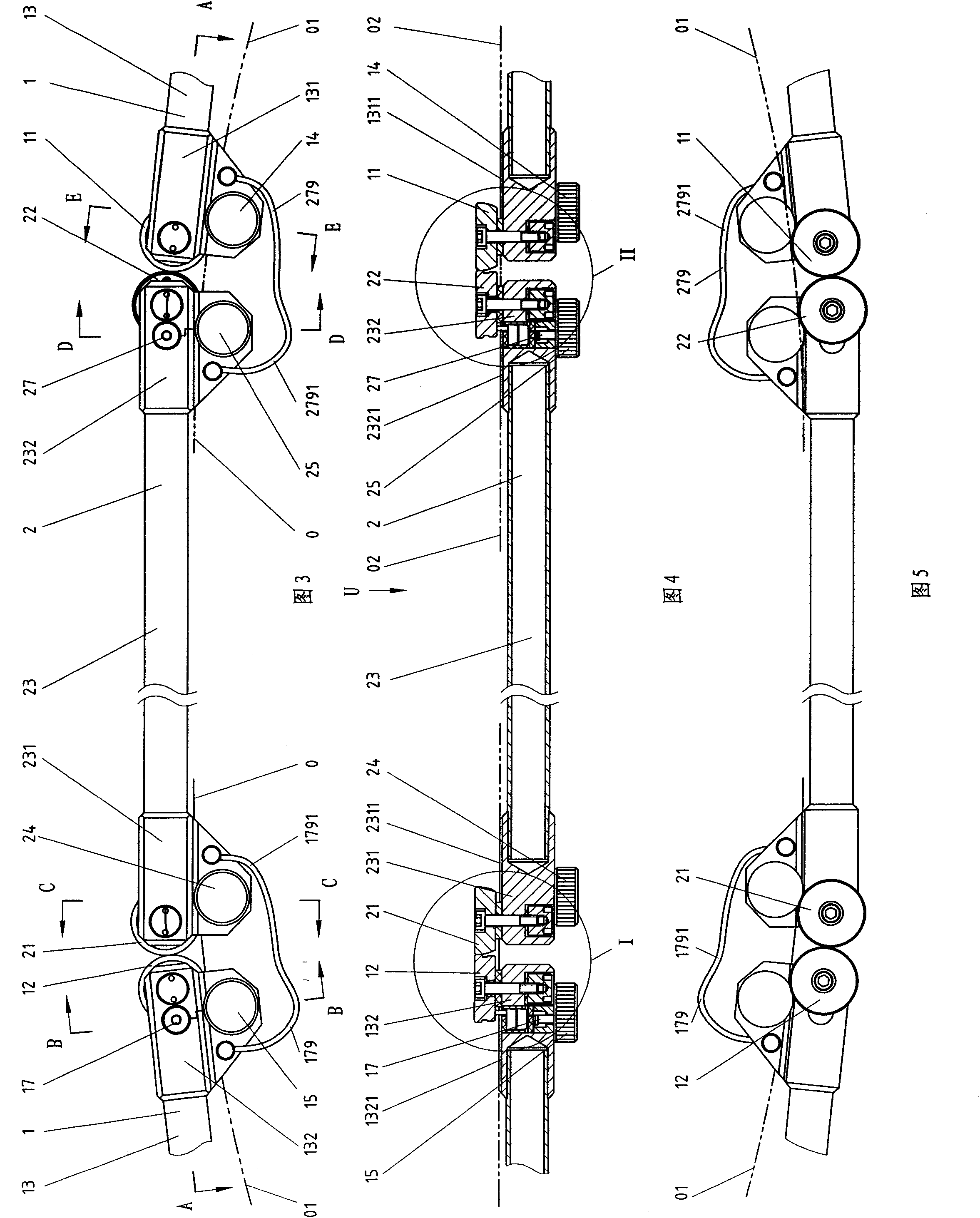

[0047] Such as figure 1 As shown, it is a schematic diagram of a contact indication method based on a measurement unit pair with an insulated surface of the measured object in Embodiment 1 of the present invention. The steps of the contact indication method are as follows:

[0048] Step 1) Take a measuring unit pair; said measuring unit pair is made up of measuring unit A 1 and measuring unit B 2, wherein measuring unit A 1 comprises: a body A 13, a first positioning unit connected to both sides of the body A 13 respectively Element A 11 and the second positioning element A 12, wherein the outer surfaces of the first positioning element A 11 and the second positioning element A 12 are cylindrical or spherical; the measuring unit B 2 includes: a body B 23 connected to The first positioning element B 21 and the second positioning element B 22 on both sides of the body B 23, wherein the outer surfaces of the first positioning element B 21 and the second positioning element B 22 a...

Embodiment 2

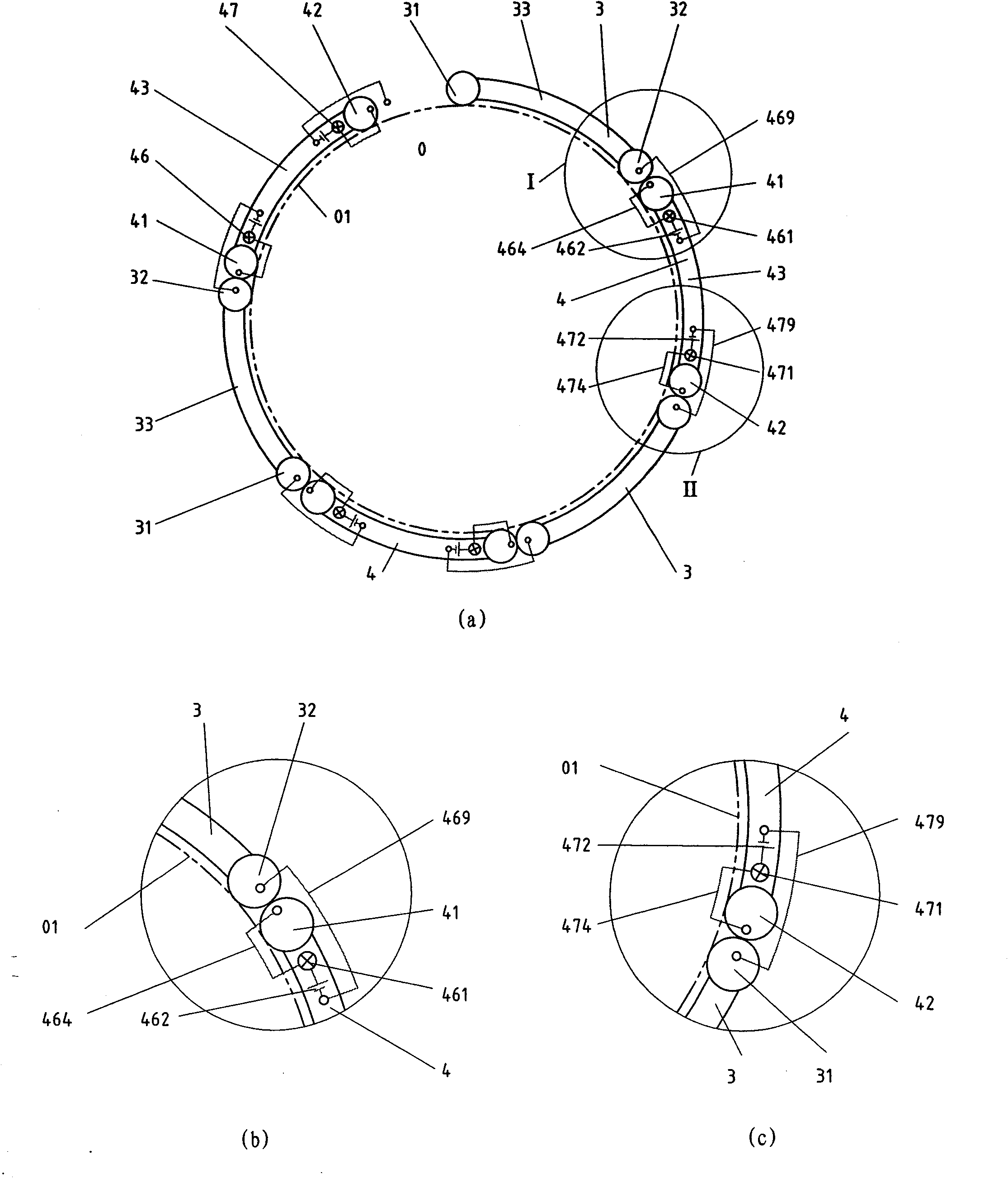

[0059] Such as figure 2 As shown, it is a schematic diagram of another contact indication method based on the measurement unit pair with insulated surface of the measured object in Embodiment 2 of the present invention. The steps of the contact indication method are as follows:

[0060]Step 1) Take a measuring unit pair; said measuring unit pair is made up of measuring unit C3 and measuring unit D4, wherein measuring unit C3 comprises: a body C33, a first positioning unit respectively connected to both sides of the body C33 Element C 31 and second positioning element C 32, wherein the outer surfaces of the first positioning element C 31 and the second positioning element C 32 are cylindrical or spherical; the measuring unit D 4 includes: a body D 43, connected to The first positioning element D 41 and the second positioning element D 42 on both sides of the body D 43, wherein the outer surfaces of the first positioning element D 41 and the second positioning element D 42 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com