Method for calibrating infrared probe of shaft temperature detection system by adopting vertical zigzag plate

A shaft temperature detection and infrared probe technology, applied in the field of temperature measurement, can solve the problems of cumbersome operation, long working time, misalignment of optical paths, etc., and achieve the effect of ensuring accuracy and ensuring train safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

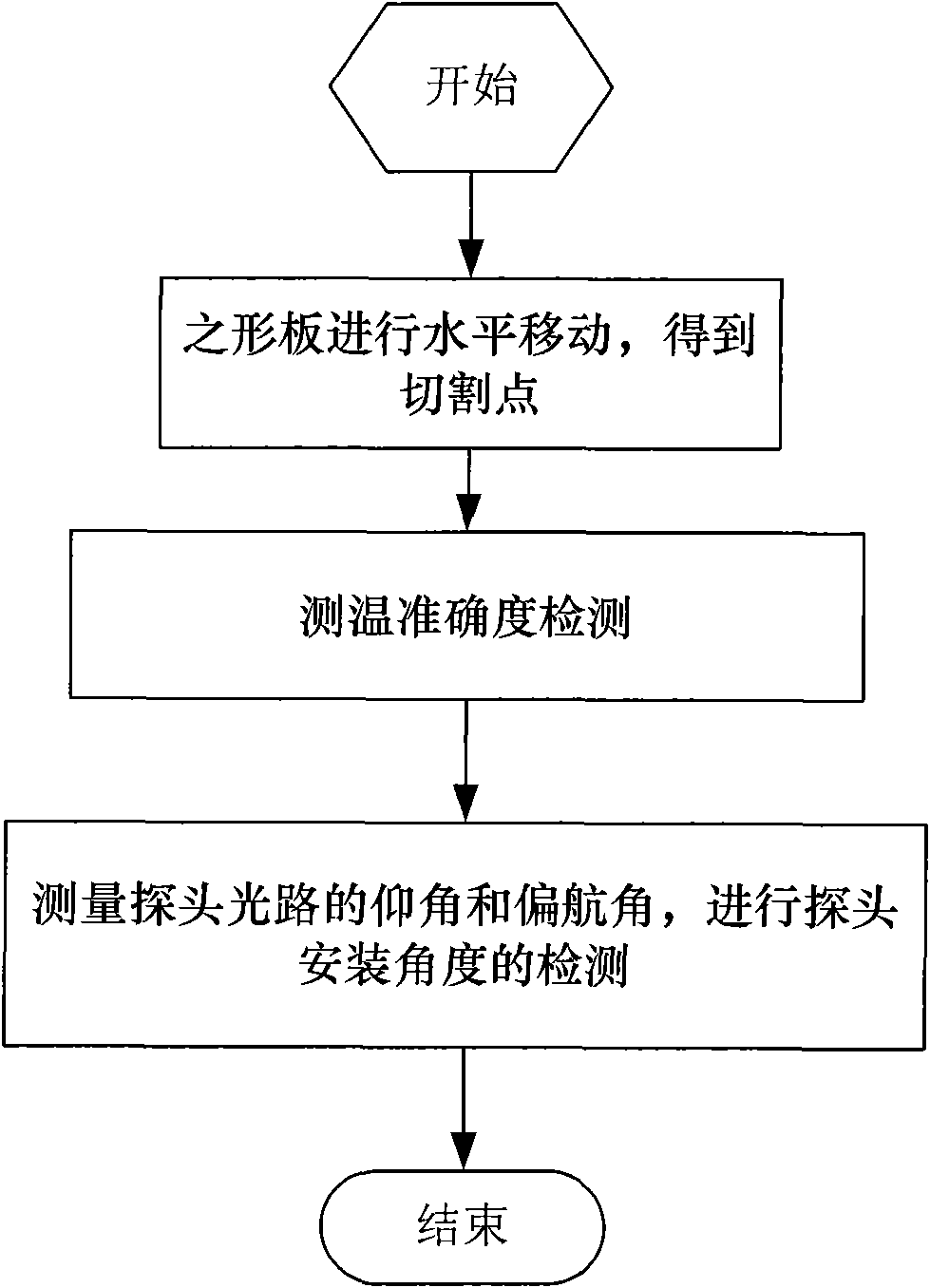

[0097] The present invention is a method for calibrating the infrared probe of the axial temperature detection system by using a vertical shaped plate, the process is as follows figure 1 shown, including the following steps:

[0098] Step 1: The shape plate is moved horizontally to obtain the cutting point;

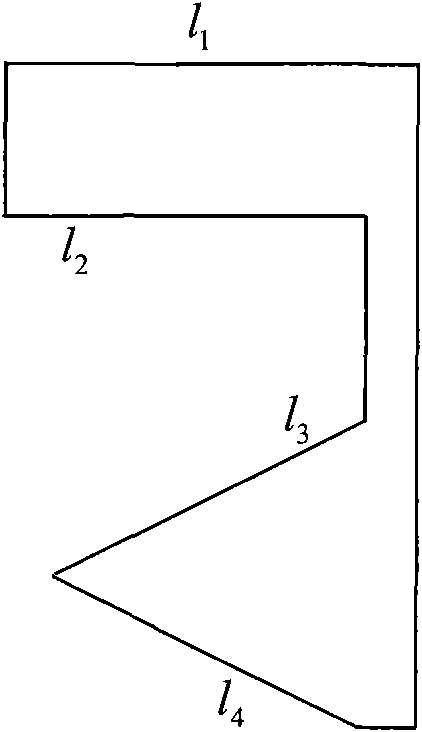

[0099] shape like figure 2 As shown, it is placed vertically between the probe and the black body, and at the same time perpendicular to the horizontal direction and the direction of the rail, and the two sides parallel to the horizontal direction are l 1 and l 2 , the two hypotenuses are l 3 and l 4 ;

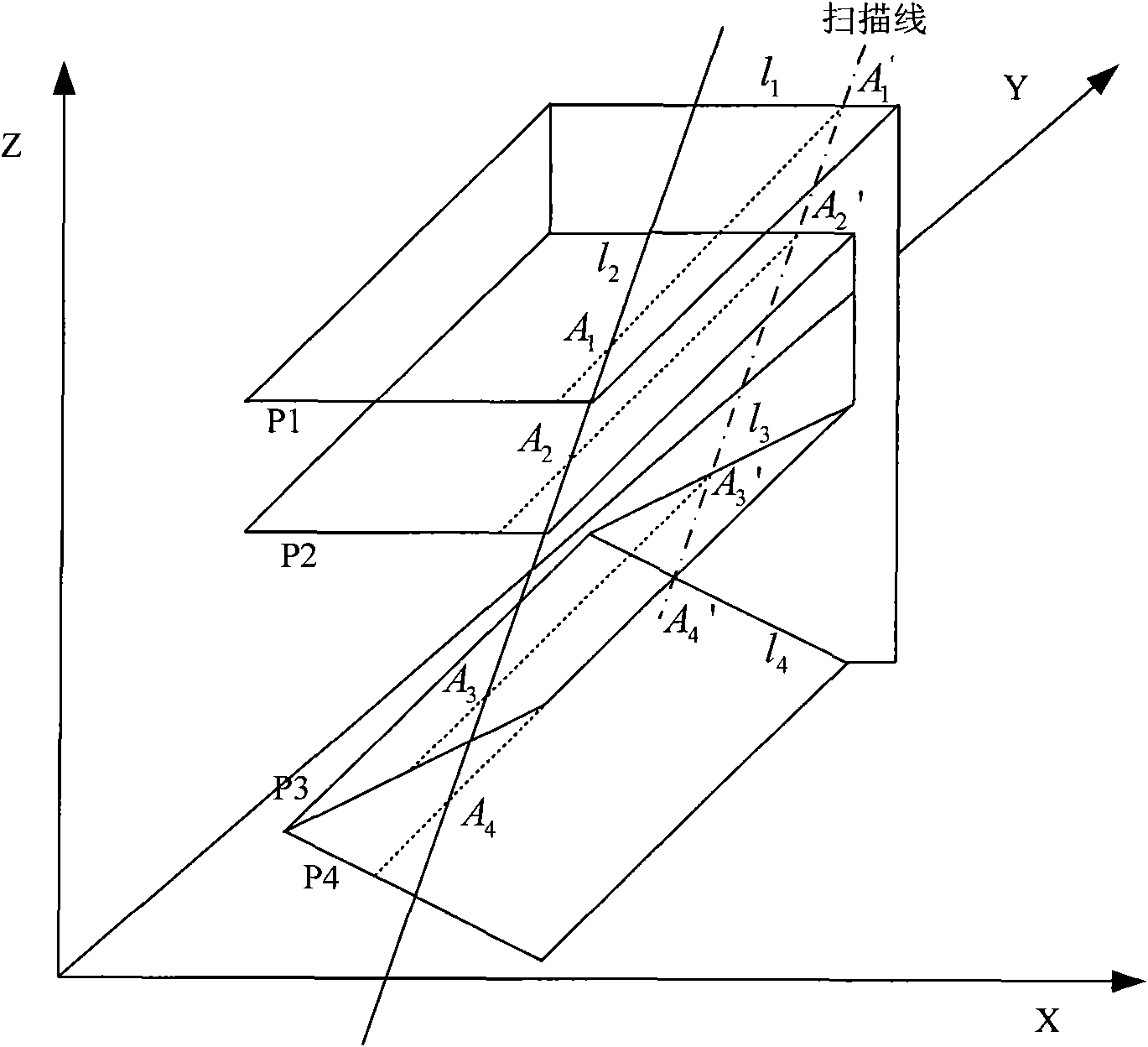

[0100] The Cartesian coordinate system is used, the x-axis is the direction perpendicular to the rails in the horizontal plane, from the inside of the rails to the outside of the rails, the y-axis is the direction parallel to the rails in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com