Antipollution flashover disk-shaped insulator

An anti-pollution flashover technology for insulators, applied to insulators, electrical components, circuits, etc., can solve problems such as pollution accumulation, pollution flashover, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

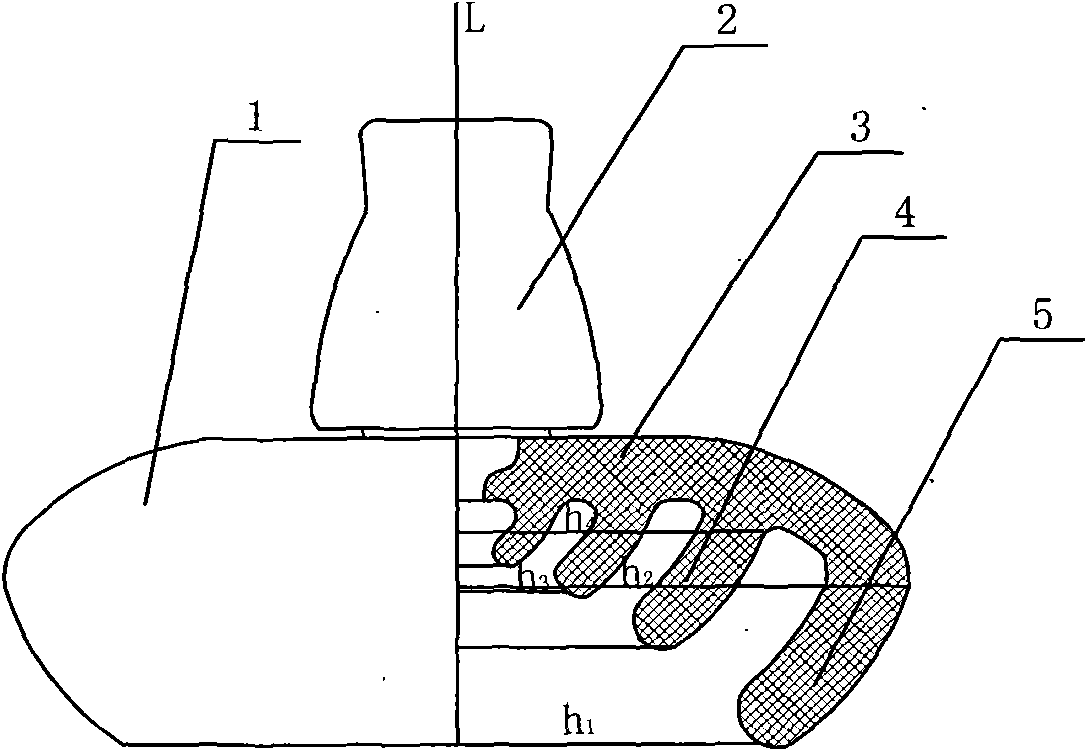

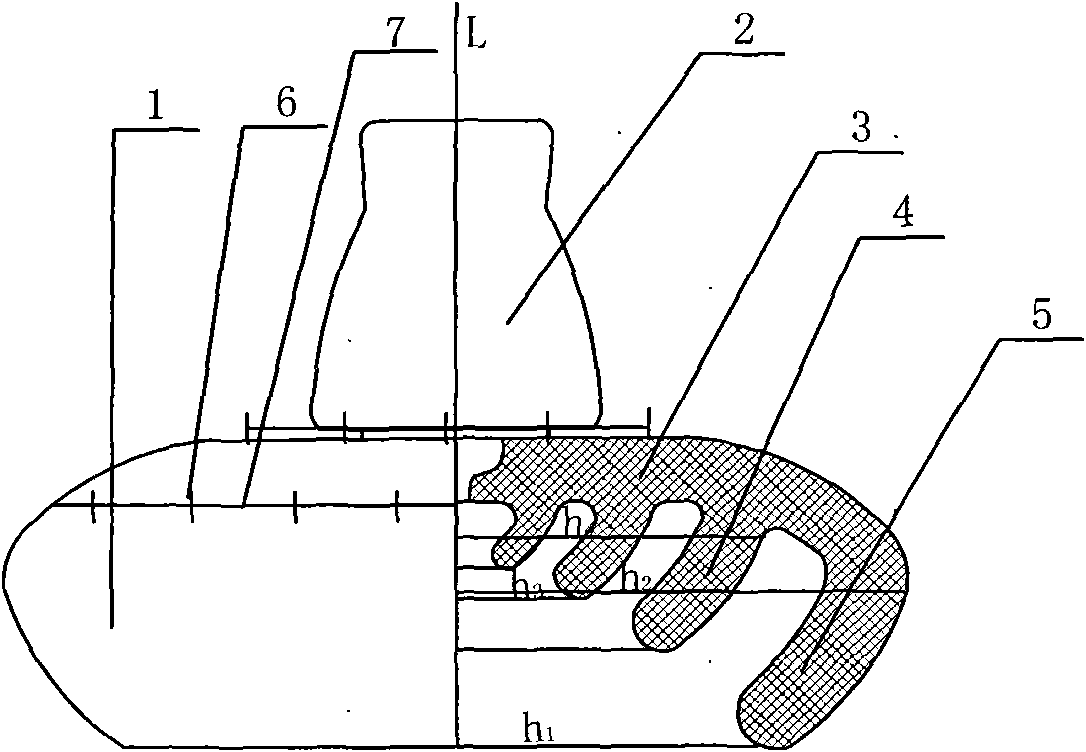

[0014] like figure 1 , figure 2 The shown anti-fouling flash disk insulator includes an umbrella plate 3 with an iron cap 2. The lower surface of the umbrella plate 3 is provided with an annular umbrella edge 4 and a drip edge 5. The drip edge 5 is integrated with the umbrella plate, and the drip edge The distance h between the bottom end of the disc insulator and the axis L of the disc insulator 1 Less than the distance h between the uppermost end of the dripping water and the axis L of the disc insulator 2 , the distance h between the lowermost end of the annular umbrella edge 4 and the axis L of the disc insulator 3 Less than the distance h between the uppermost end of the umbrella edge and the axis L of the disc insulator 4 , there are at least two umbrella ribs, and the lengths of the umbrella ribs gradually become smaller from the outside to the inside.

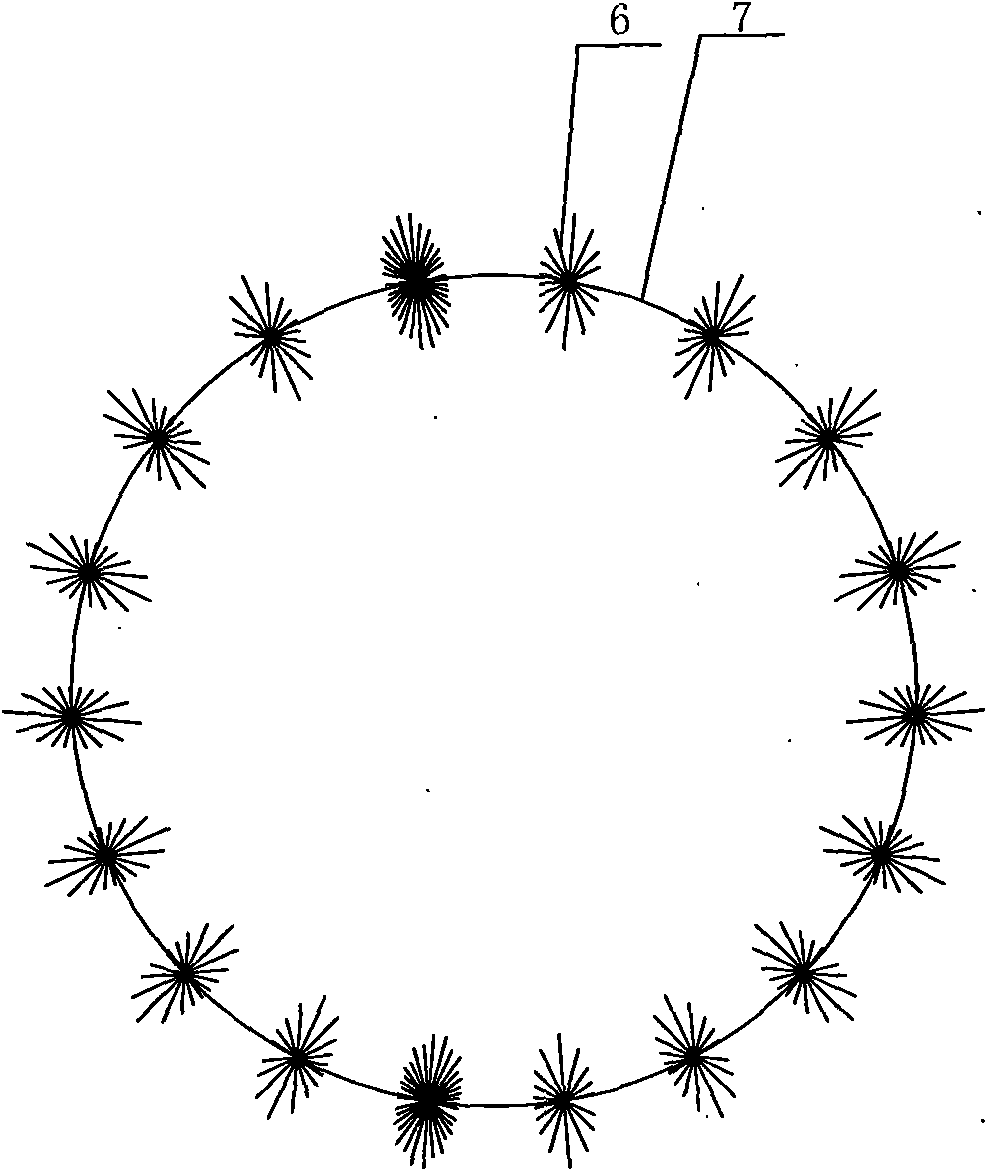

[0015] The preferred structure of the present invention is as figure 2 and image 3 As shown, an insulating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com