Power module insulation method and power module assembly

A technology for power modules and components, applied in electrical components, electric solid devices, semiconductor devices, etc., can solve the problem of impracticality, no good solution, and difficulty in injecting three-proof glue into PCB and power module three-proof glue, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments shown and described herein are for illustration only, and are not intended to limit the present invention.

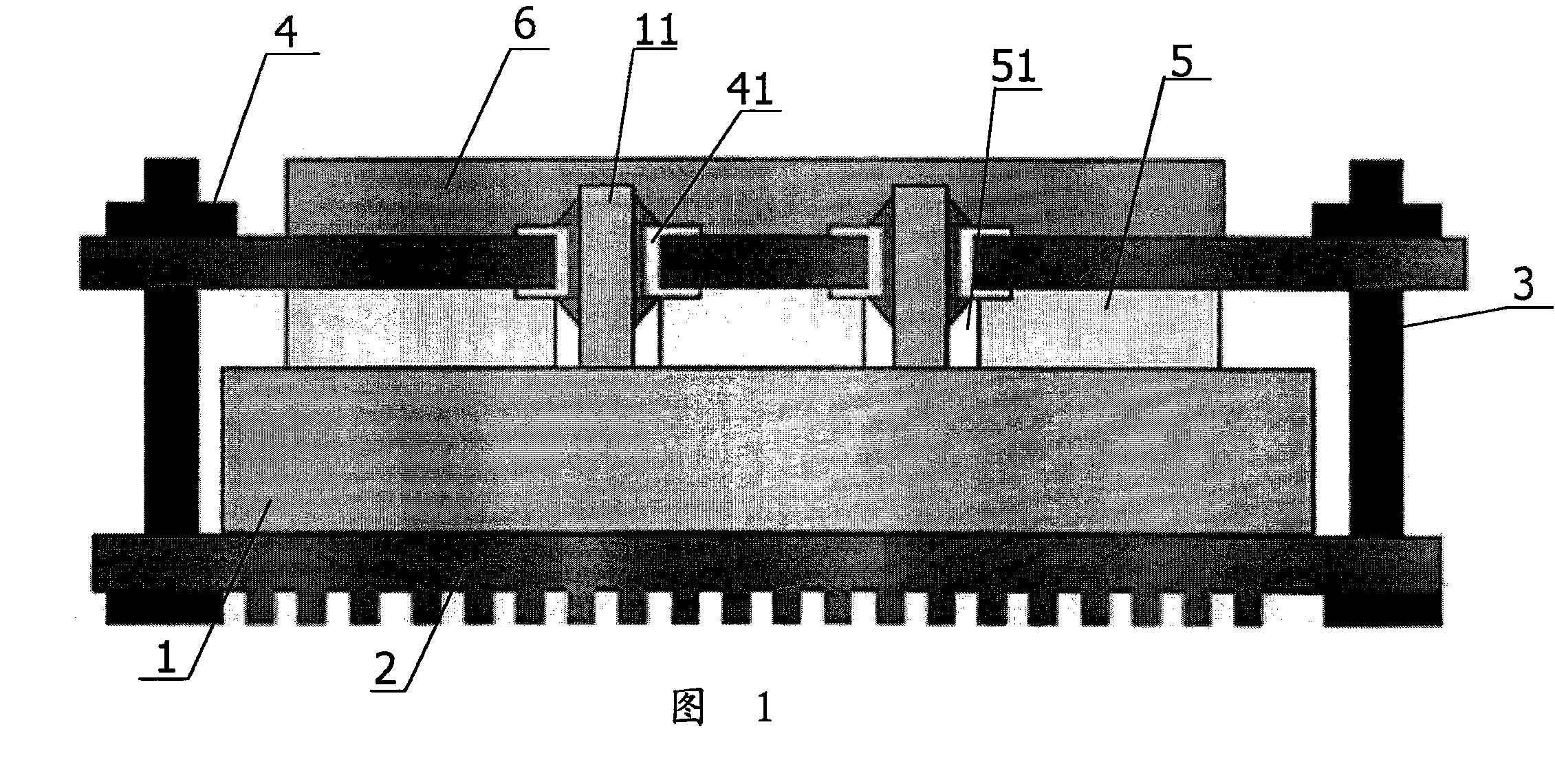

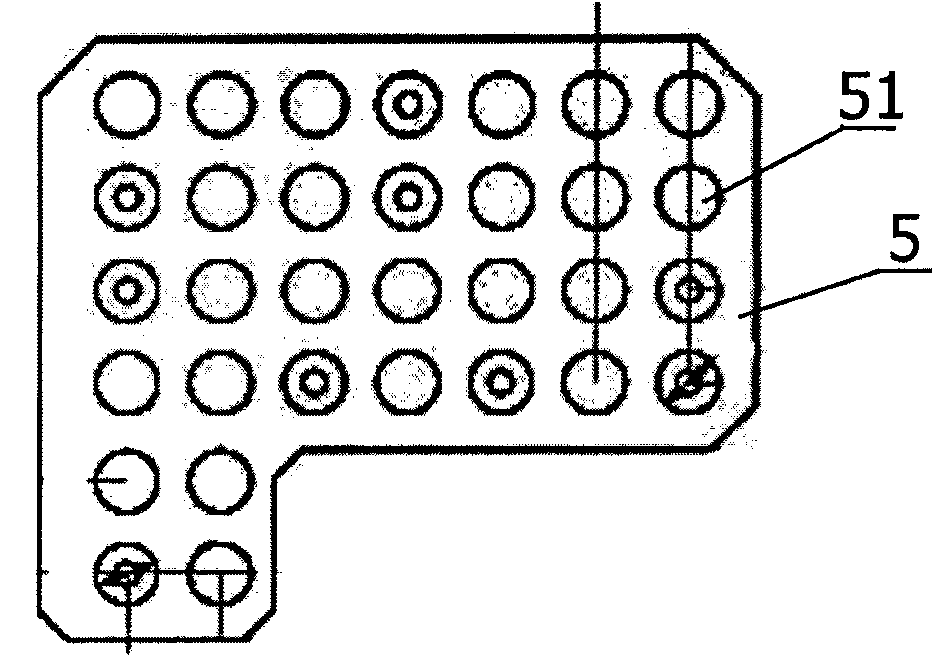

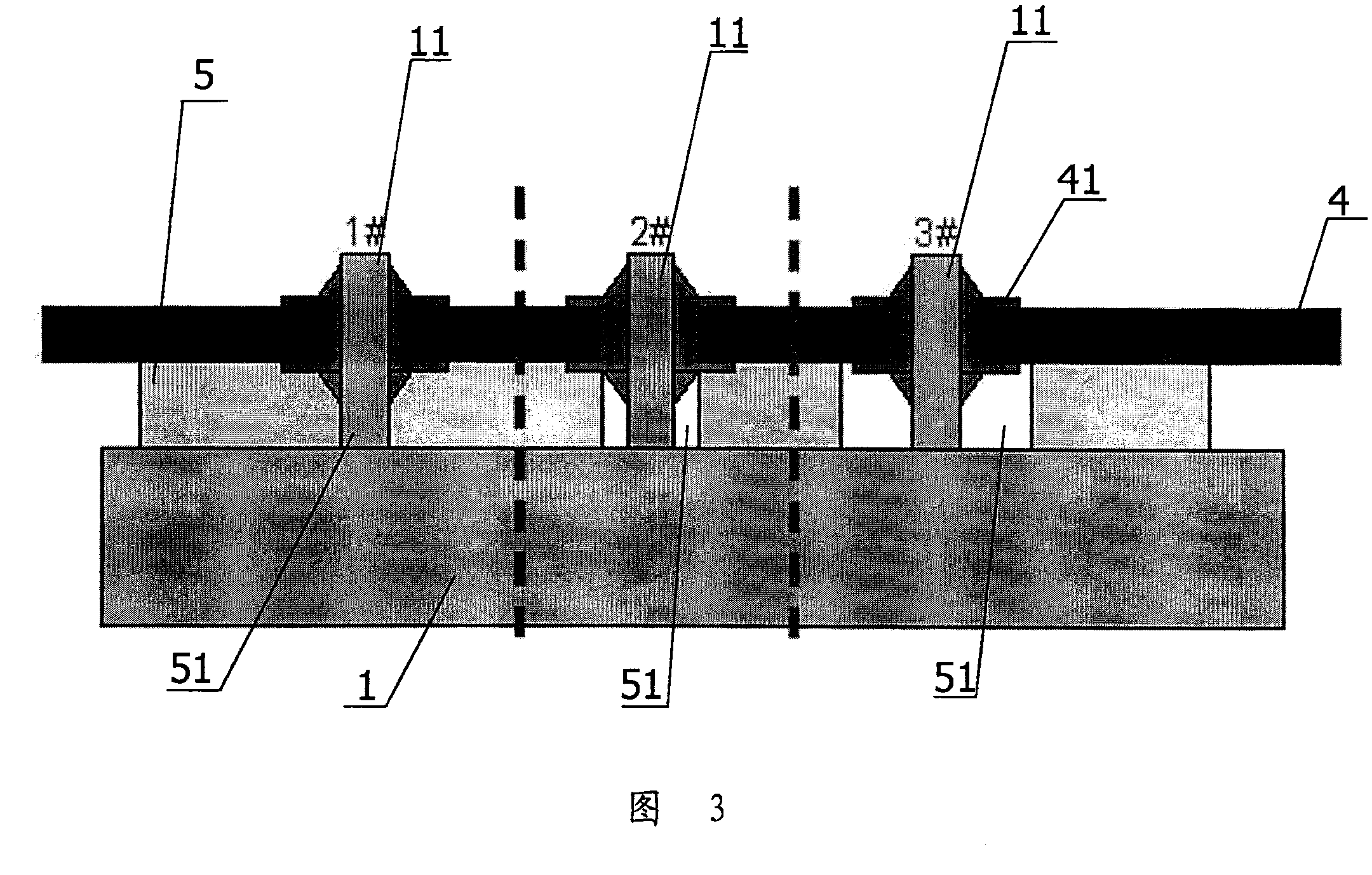

[0024] like figure 1 As shown, usually the power module 1 and the heat sink 2 are installed together, and then the pins 11 of the power module 1 are inserted into the corresponding pads 41 on the printed circuit board 4 . And the heat sink 2 and the printed circuit board 4 are connected together by bolts 3 , so that the power module 1 and the printed circuit board 4 are installed together. Then, the printed circuit board 4 is turned over, and each pin 11 protruding from the pad 41 is soldered, so as to complete the mechanical and electrical connection between the power module 1 and the printed circuit board 4 .

[0025] However, as mentioned in the background art, as the size of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com