System for preparing pollution-level 65# cooling fluid and process

A technology of pollution degree and cooling liquid, which is applied in the direction of mixer accessories, mixers, instruments, etc., can solve the problem of no manufacturer's preparation, achieve the effect of reducing pollution level, improving pollution level, and stable and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

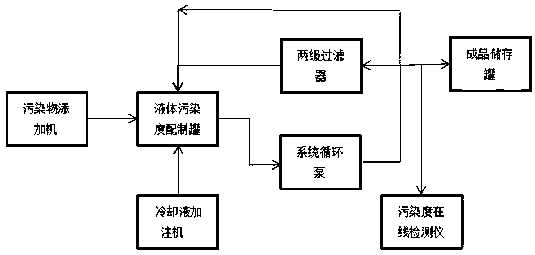

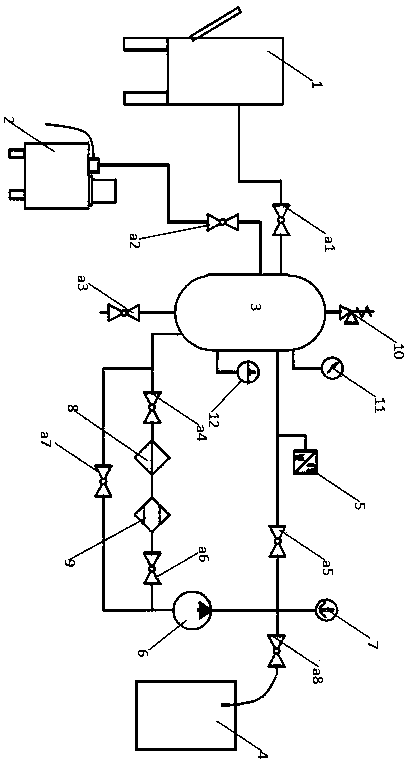

[0030] Below in conjunction with the accompanying drawings the present invention is further described; the liquid pollution degree preparation tank is provided with a coolant inlet, a coolant outlet, a coolant circulation port, a coolant discharge port, a safety valve (10), a pressure gauge (11) and a liquid level Count (12). The pollutant adding machine (1) and the coolant filling machine (2) are respectively connected to the coolant inlet of the liquid pollution degree preparation tank (3) through pipelines, and the pollutant addition machine (1) is connected to the liquid pollution degree preparation tank (3) Ball valve I (a1) is installed on the pipeline between them, and ball valve II (a2) is installed on the pipeline between the coolant filling machine (2) and the liquid pollution degree preparation tank (3). The coolant outlet of the liquid pollution degree preparation tank (3) is connected to the finished product storage tank (4) through a pipeline and the pollution de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com