Vector controller of alternating current asynchronous motor

An AC asynchronous motor and vector controller technology, applied in the field of power equipment, can solve problems such as incomplete current overcurrent and voltage undervoltage protection functions, motor burnout, and easily damaged IGBTs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] Example.

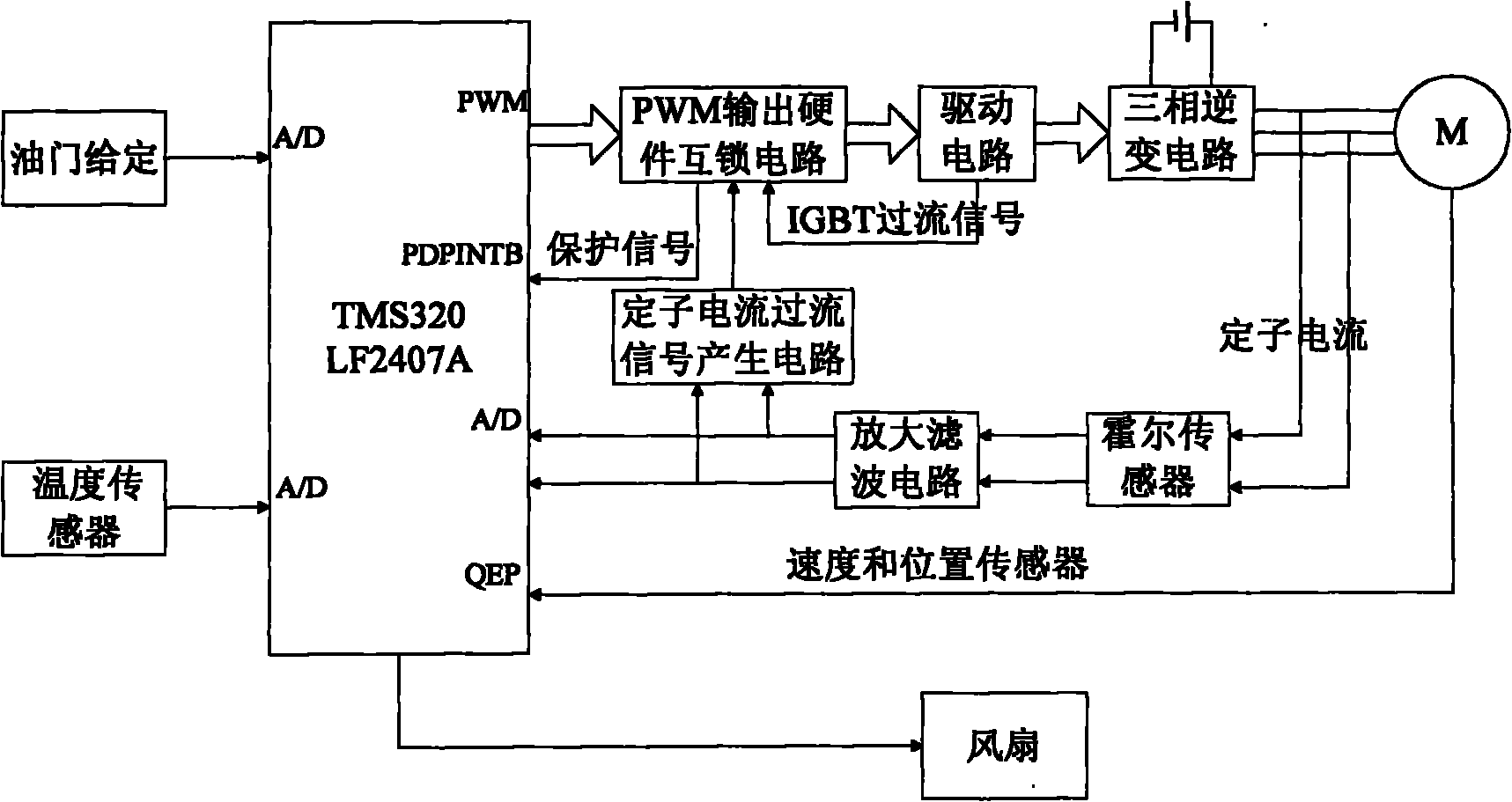

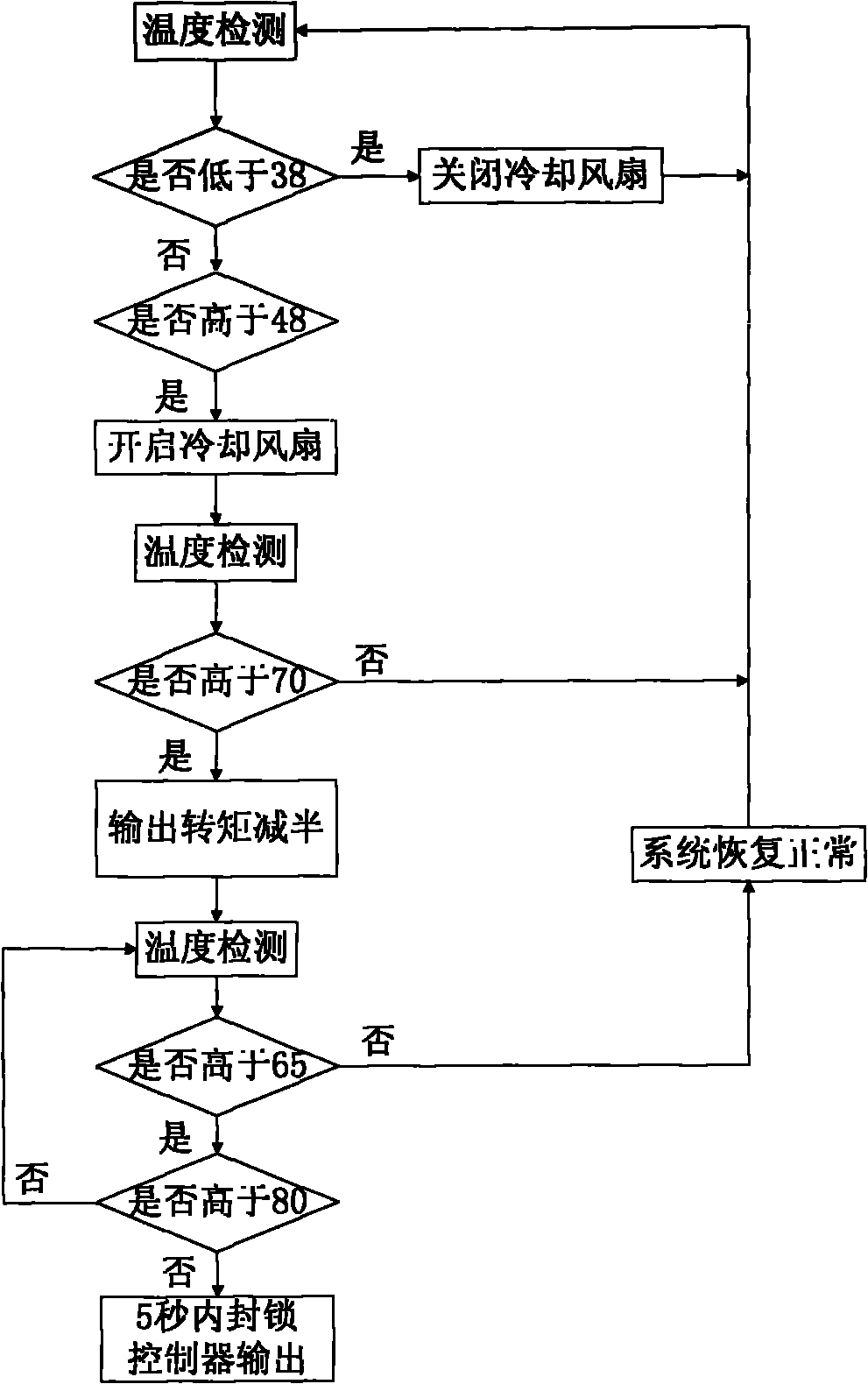

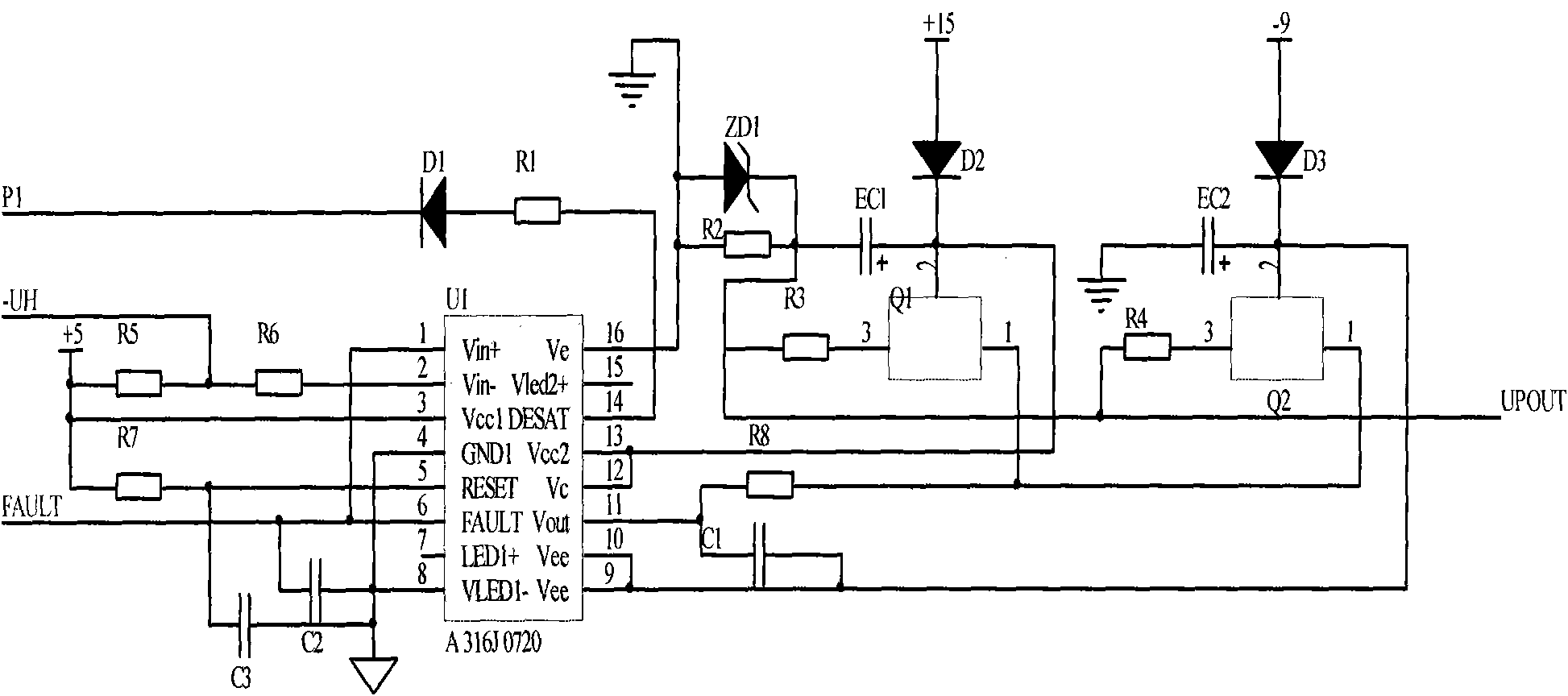

[0028] This example figure 1 As shown, the controller includes the control chip TMS320LF2407A, PWM output hardware interlock circuit, drive circuit, three-phase inverter circuit, motor, Hall sensor, amplification filter circuit, stator current overcurrent signal generation circuit, temperature sensor, fan, etc. The control chip TMS320LF2407A is connected to the PWM output hardware interlock circuit, drive circuit, three-phase inverter circuit, and motor in turn through the PWM port; the Hall sensor is connected to the A / F of the control chip TMS320LF2407A through the amplification filter circuit after extracting the stator current of the motor. D port, the amplification and filtering circuit is connected to the PWM output hardware interlock circuit through the stator current overcurrent signal generation circuit; the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com