Control device of permanent magnetic contactor

A technology for control devices and contactors, applied in emergency protection circuit devices, relays, non-polar relays, etc., can solve problems such as coil burnout, power consumption, and large working current, and achieve the effects of strong breaking capacity, material saving, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

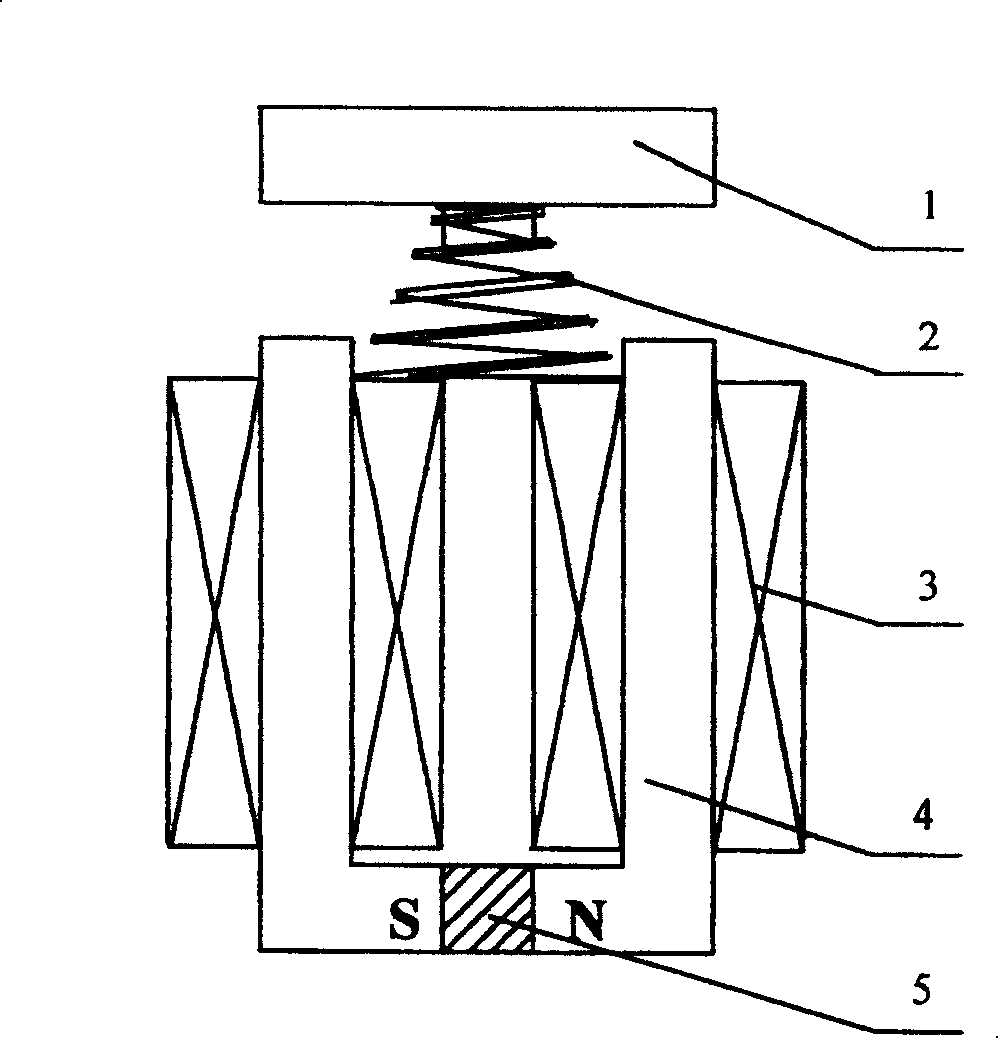

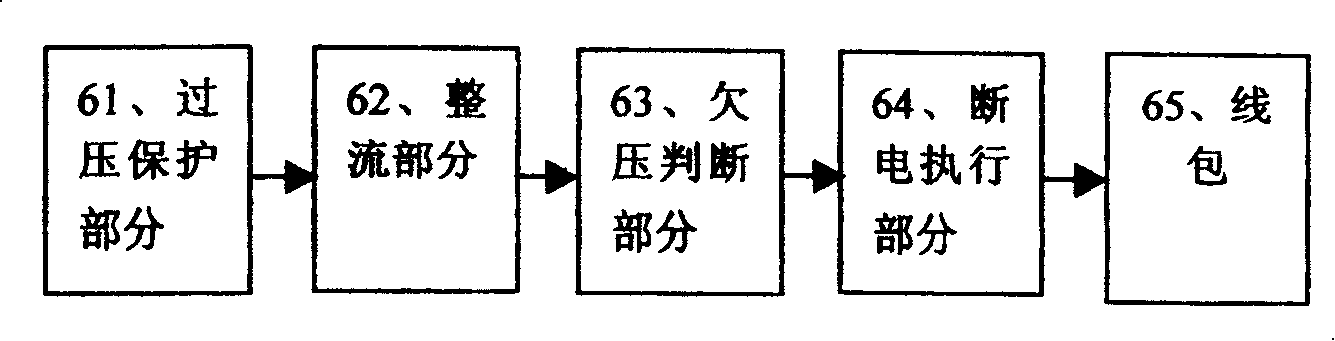

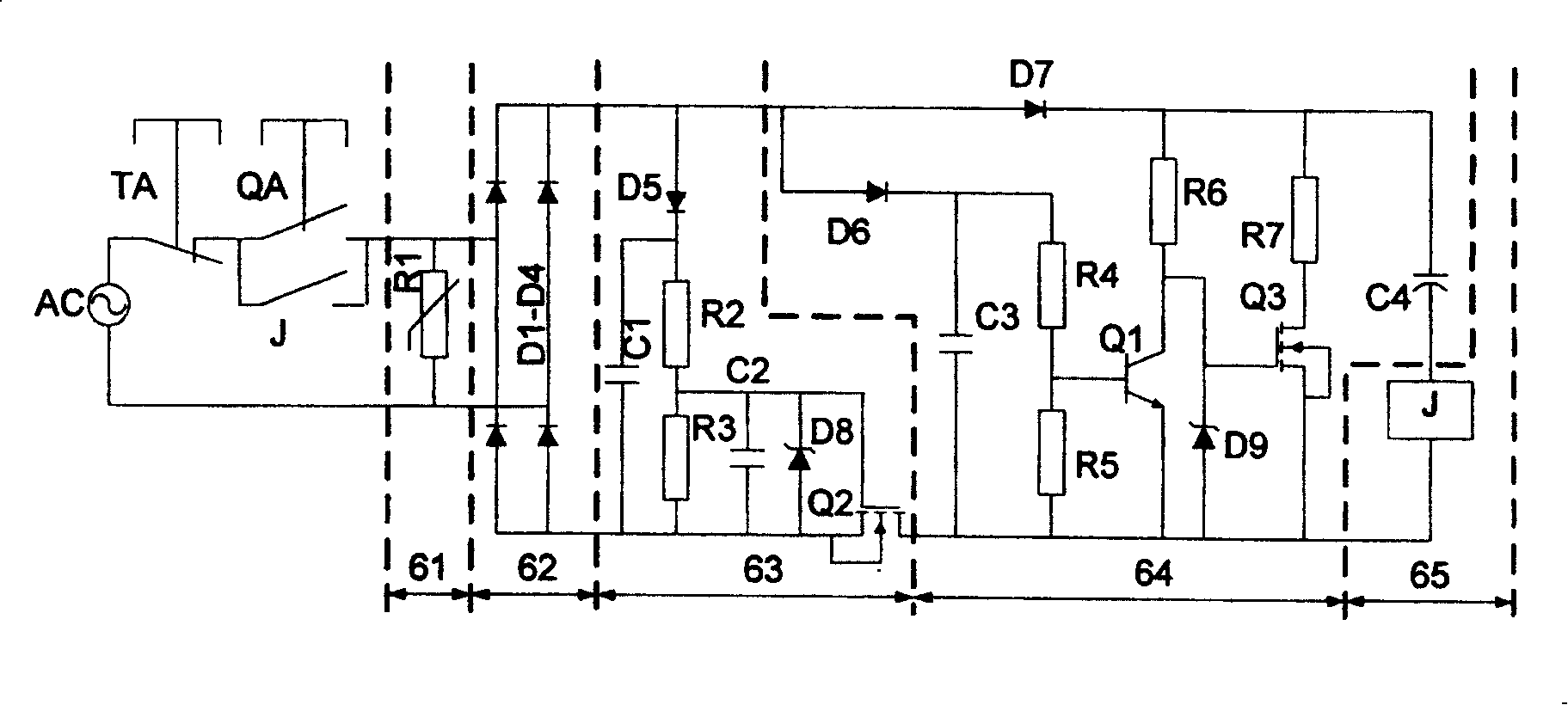

[0017] The permanent magnet contactor of the present invention is made up of moving iron core 1, static iron core 4, permanent magnet steel 5, coil 3, tower spring 2 and control circuit, is characterized in that: between two static iron cores 4, set There is a permanent magnetic steel 5, so that two static iron cores 4 and a permanent magnetic steel 5 form a "U"-shaped whole, and there is a coil 3 on each of the left and right static iron cores 4, and the phase between the two coils 3 They are connected in series and have the same polarity direction; the tower spring 2 is supported on the skeleton of the coil 3; the upper end of the tower spring 2 is connected with the moving iron core 1. The moving iron core 1 and the static iron core 4 are made of common electrical pure iron, and the permanent magnet 5 adopts NdFeB material with high magnetic energy product.

[0018] Such as figure 1 As shown, when the switch is closed, the coil passes a positive current, which is consisten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com