Ultrasonic flaw detection method and device thereof

一种探伤装置、超声波的技术,应用在测量装置、使用声波/超声波/次声波分析固体、使用声波/超声波/次声波进行材料分析等方向,能够解决难以检测缺陷回波等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] Embodiments of the present invention will be described below with reference to the drawings.

[0115] Figure 1 to Figure 18 One embodiment of the present invention is shown.

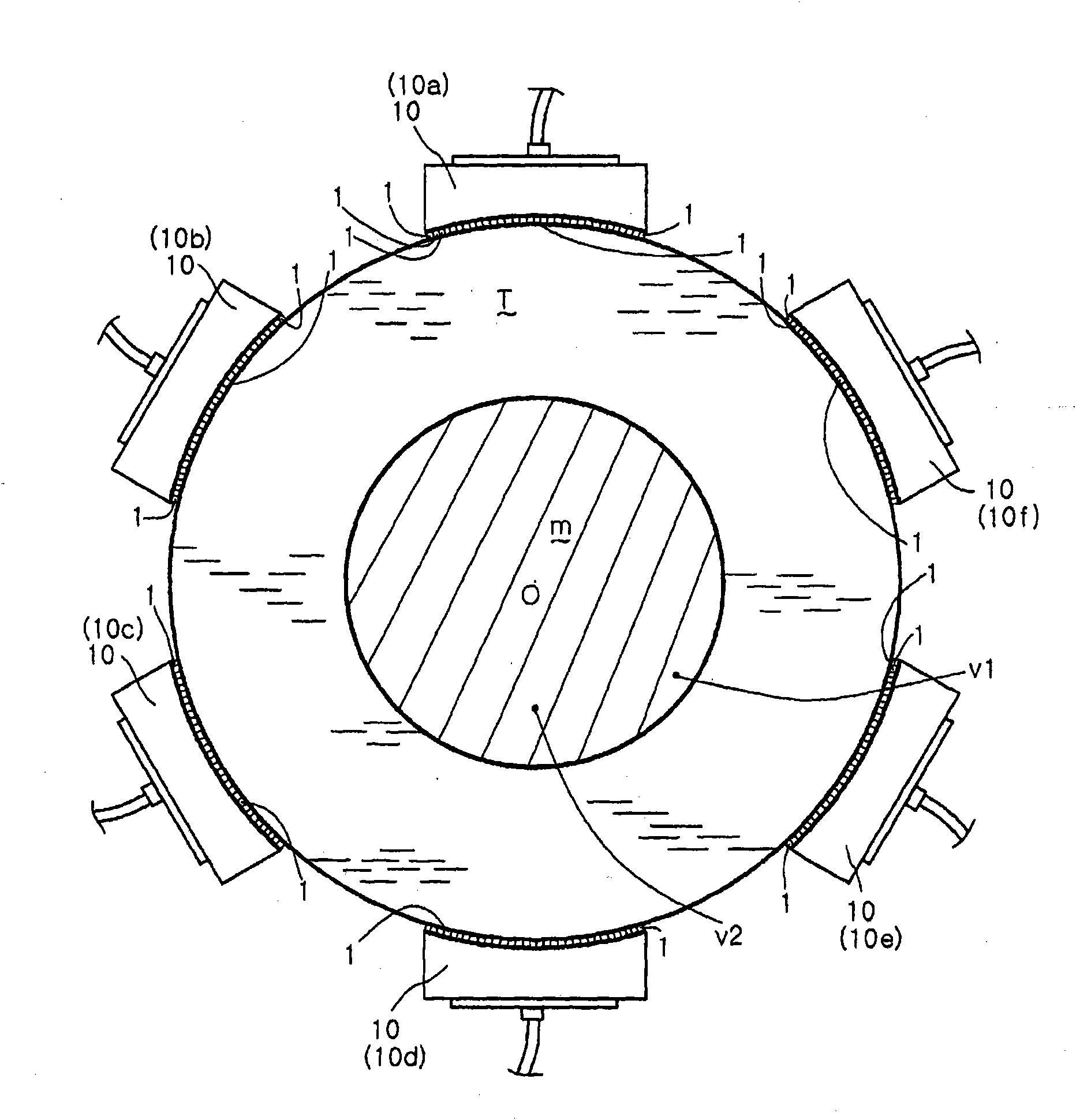

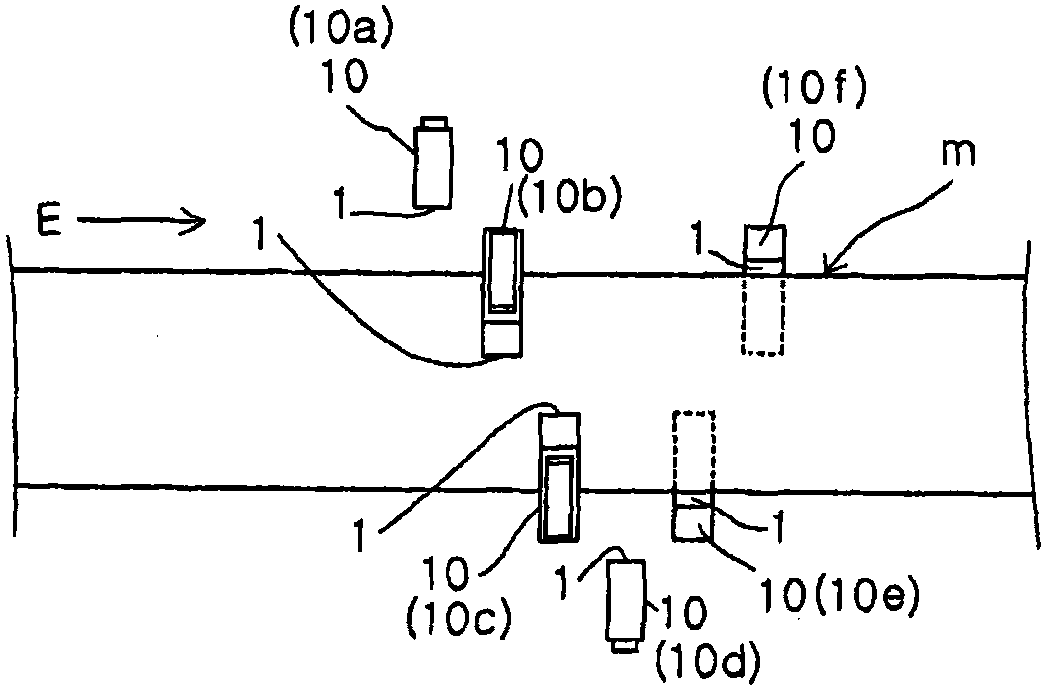

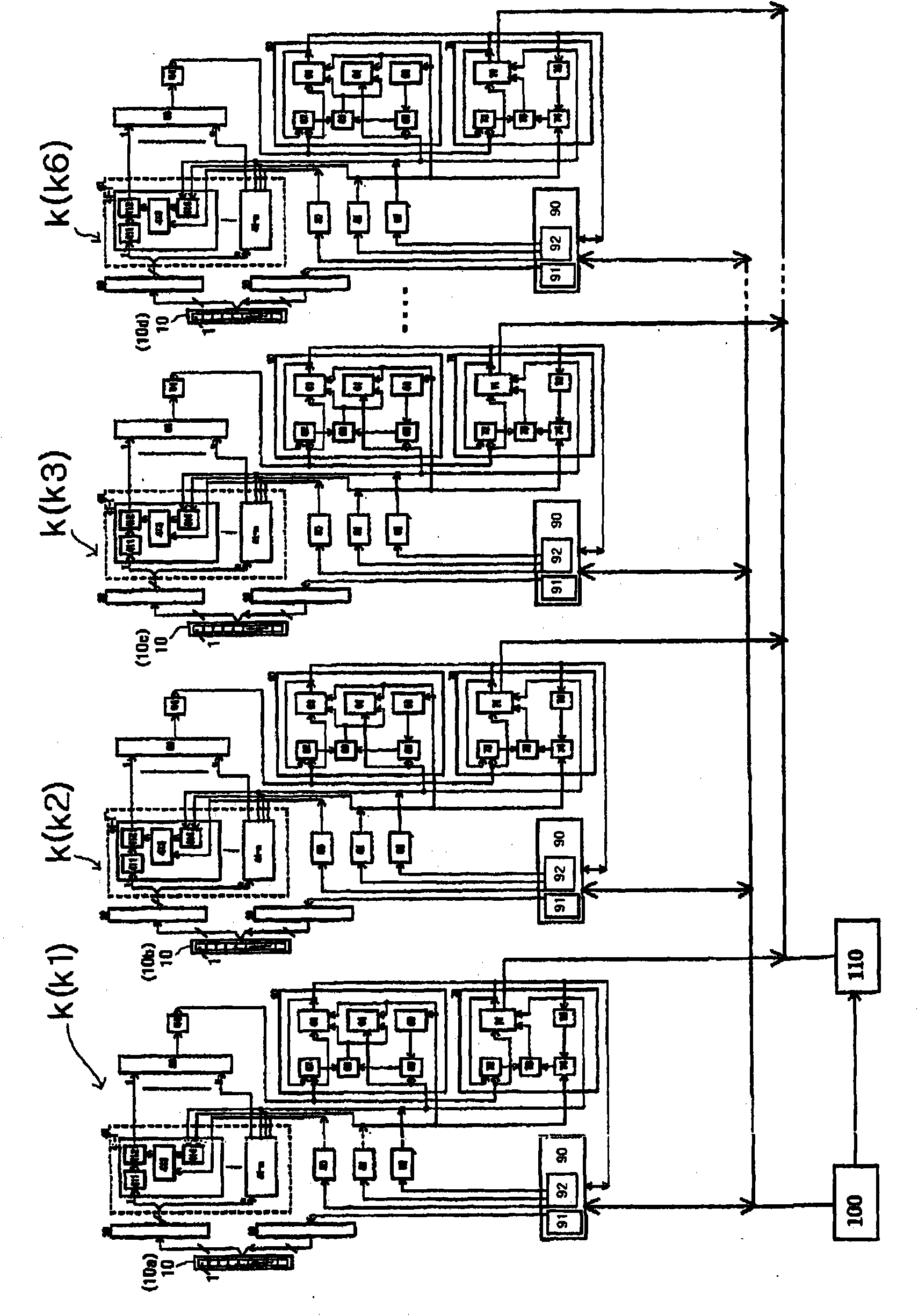

[0116] figure 1 It is a schematic cross-sectional view showing the arrangement of an array probe of a device according to an embodiment of the present invention. figure 2 It is a schematic side view showing the above arrangement. image 3 is the block diagram of the device. Figure 4 is enlarged image 3 The block diagram of the main part of the block diagram. Figure 5 It is a schematic cross-sectional view showing the focal position of ultrasonic waves of one array probe of the above-mentioned device with respect to a test material. Image 6 It is a schematic longitudinal sectional view illustrating a plane wave in volume focusing of each steel sheet as an inspection object. Figure 7 It is a schematic longitudinal sectional view illustrating volume focusing in the present invention in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com