Reciprocal rotary knife type material processor

A processing machine and material technology, applied in the field of kitchen utensils, can solve the problems of reduced crushing efficiency, insufficient impact speed and force of juice, and formation of vortices, so as to reduce machine energy consumption and noise, increase grinding effect, and process efficiency. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

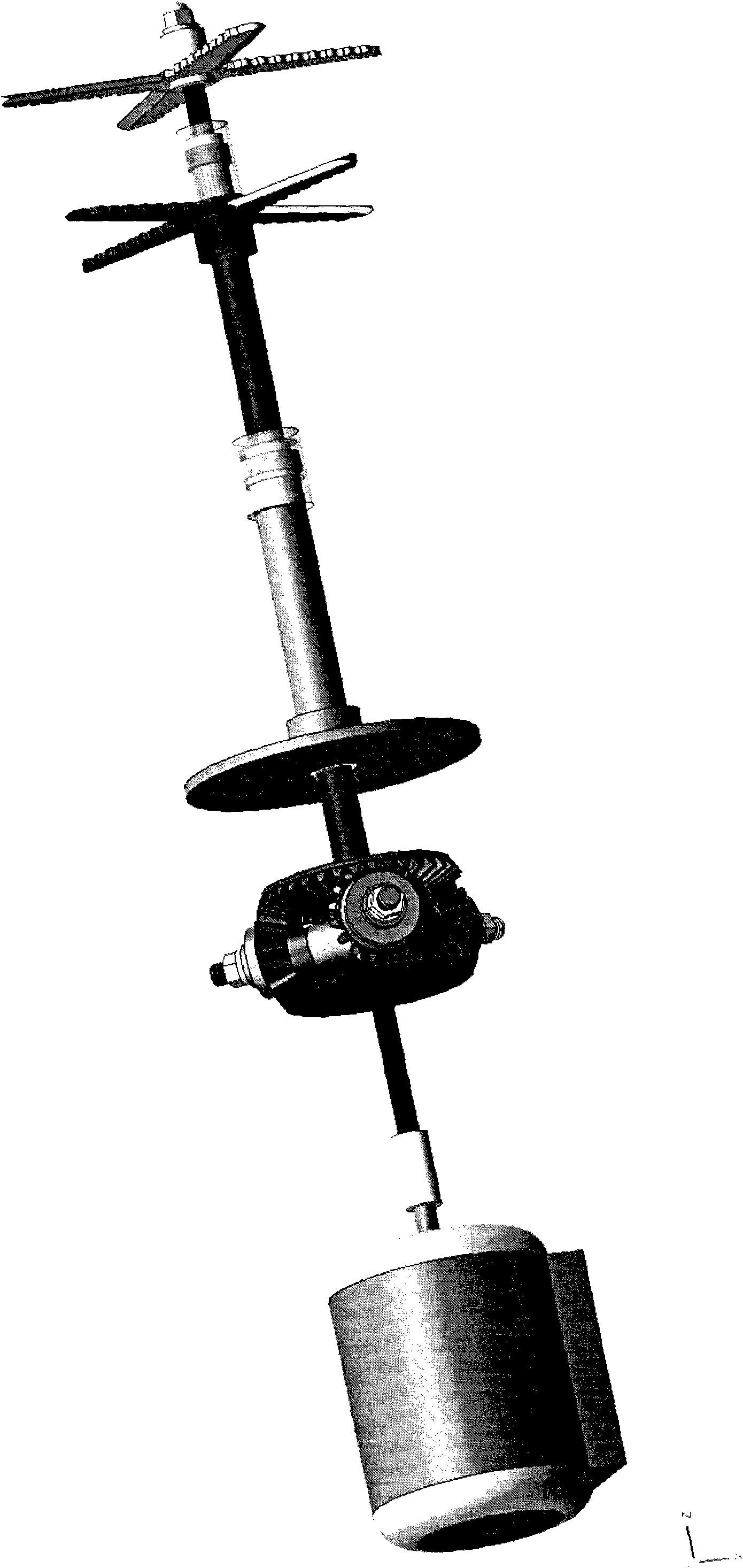

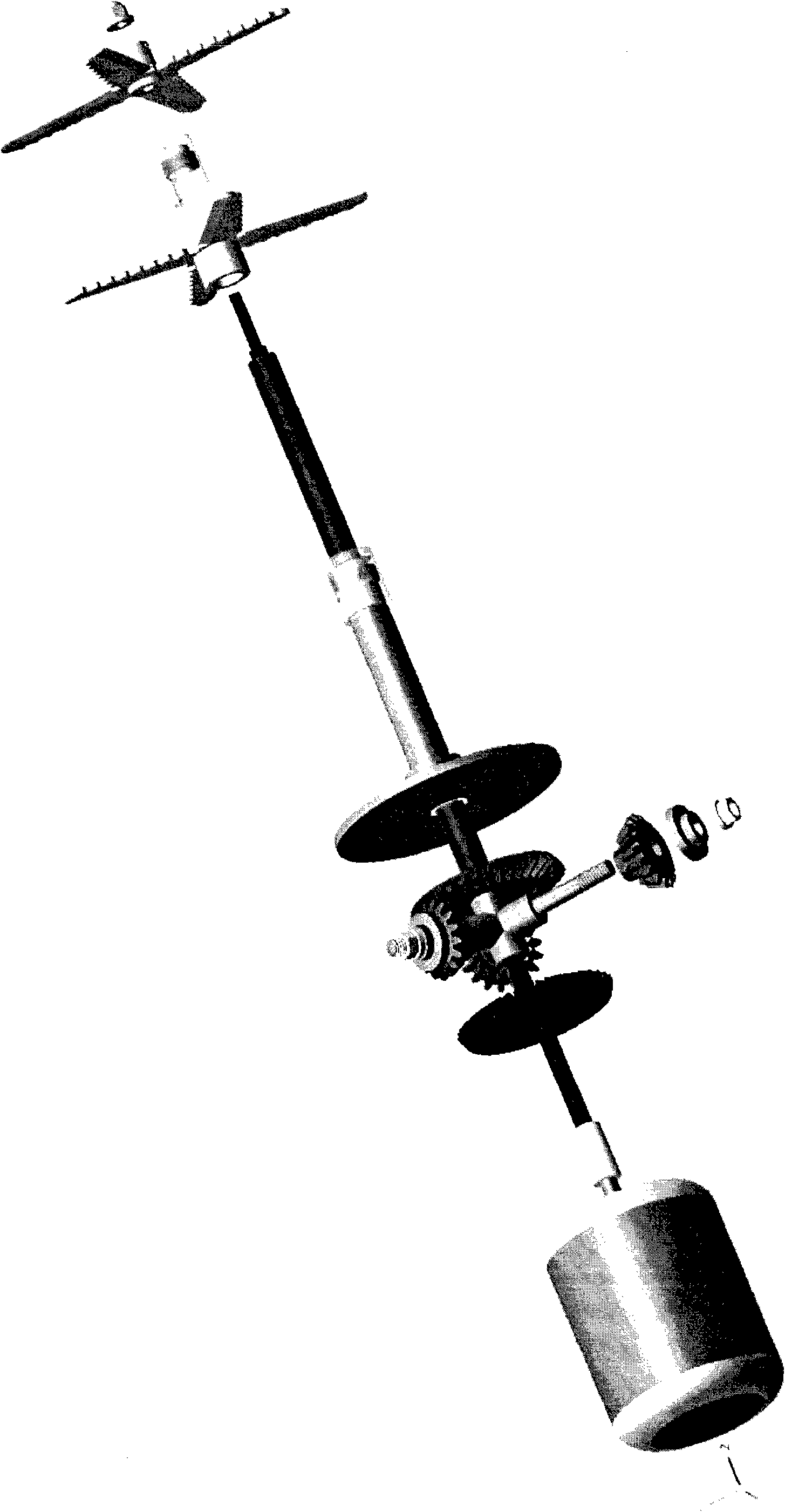

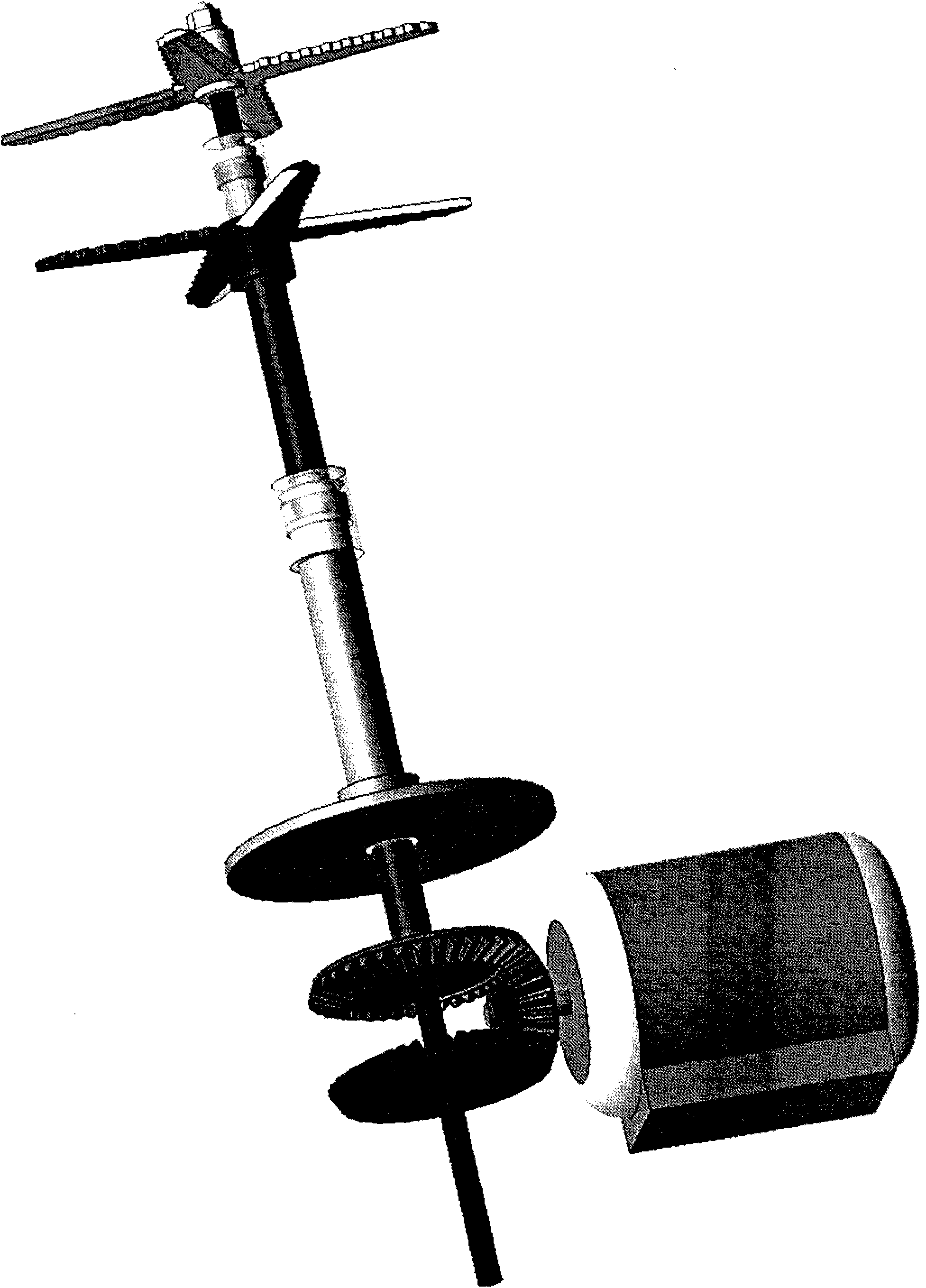

Image

Examples

Embodiment Construction

[0065] The principle of the existing single-motor-driven single-cutter shaft is relatively simple, but it has the disadvantage of single function, which is a compromise design. The speed and direction of rotation of the motor in the present invention can be controlled by the controller, and the speed and direction of rotation of the cutter on the cutter shaft will follow the control of the controller under the drive of the motor. The blade surface is made to have double-sided blades, and the blades on each side should be designed in different shapes, so that even the principle of single-motor-driven single-cutter shaft will increase the efficiency due to the different performances of the blades. This different shape can be sharp edge and blunt edge, smooth edge and serrated edge, flat edge and three-dimensional edge, or a combination of various edge shapes on multiple blades to produce different processing effects. The specific method should be determined according to the natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com