Control method of numerical-control drilling and tapping machine tool magazine

A control method and tapping machine technology, applied in the direction of digital control, electrical program control, manufacturing tools, etc., can solve the problems of poor reliability, delayed stop, high failure rate, etc., to improve accuracy and stability, and facilitate repair and maintenance , the effect of controlling production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

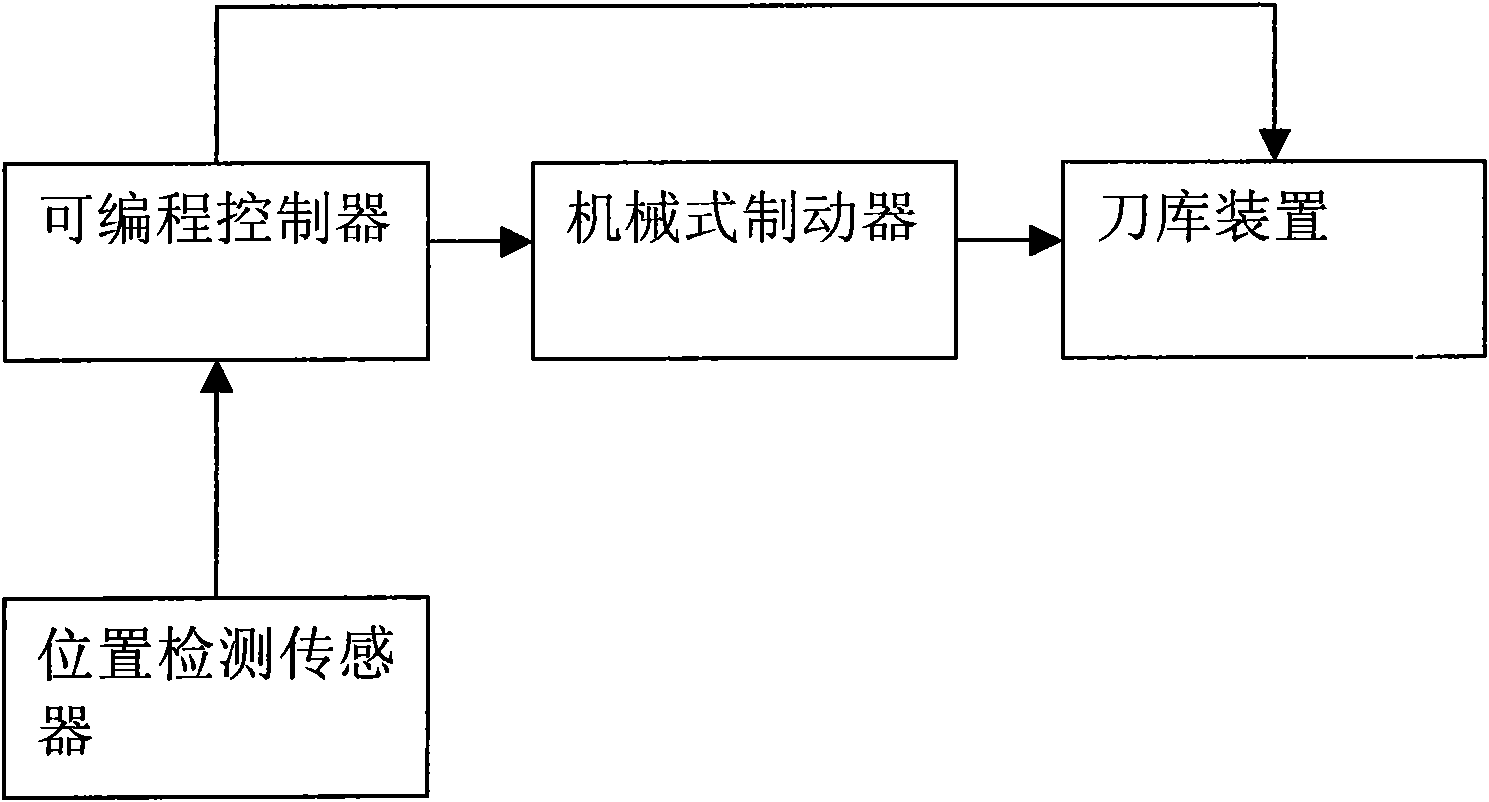

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

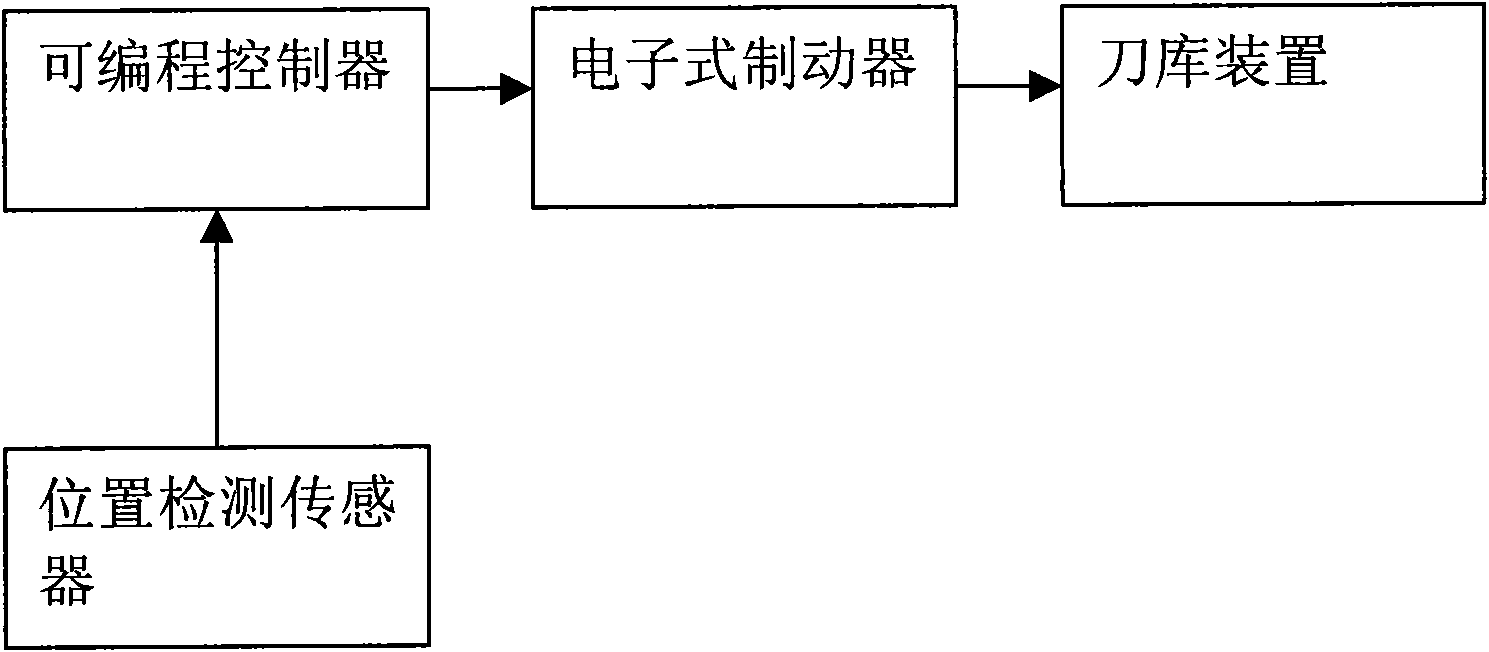

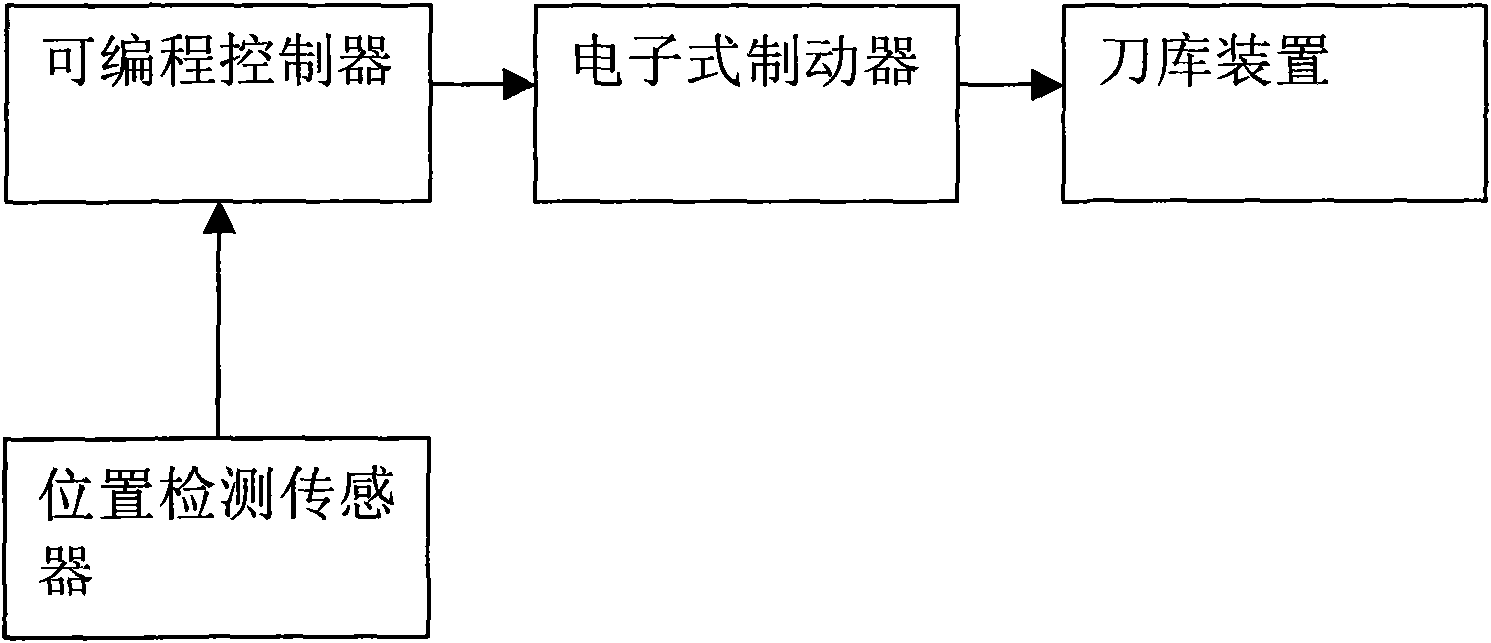

[0019] Depend on figure 2 Visible: the present invention is realized through the following steps:

[0020] The programmable controller sends commands to control the positive and negative rotation of the tool magazine to the electronic brake;

[0021] Start the tool magazine device through the electronic brake and run according to the instructions of the programmable controller;

[0022] The position detection sensor sends back the detection signal to the programmable controller;

[0023] Through the calculation and processing of the programmable controller, when the detection signal sent back meets the command requirements, the programmable controller sends a command to the electronic brake instantaneously;

[0024] The electronic brake stops the operation of the tool magazine device instantaneously upon receiving the instruction, and at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com