Three-axis servo feed transmission structure of machining center

A three-axis servo and feed transmission technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as the influence of precision retention, bearing sealing problems, thermal expansion stacking problems, etc., to improve precision and Stability, ease of repair and maintenance, and high parts generalization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

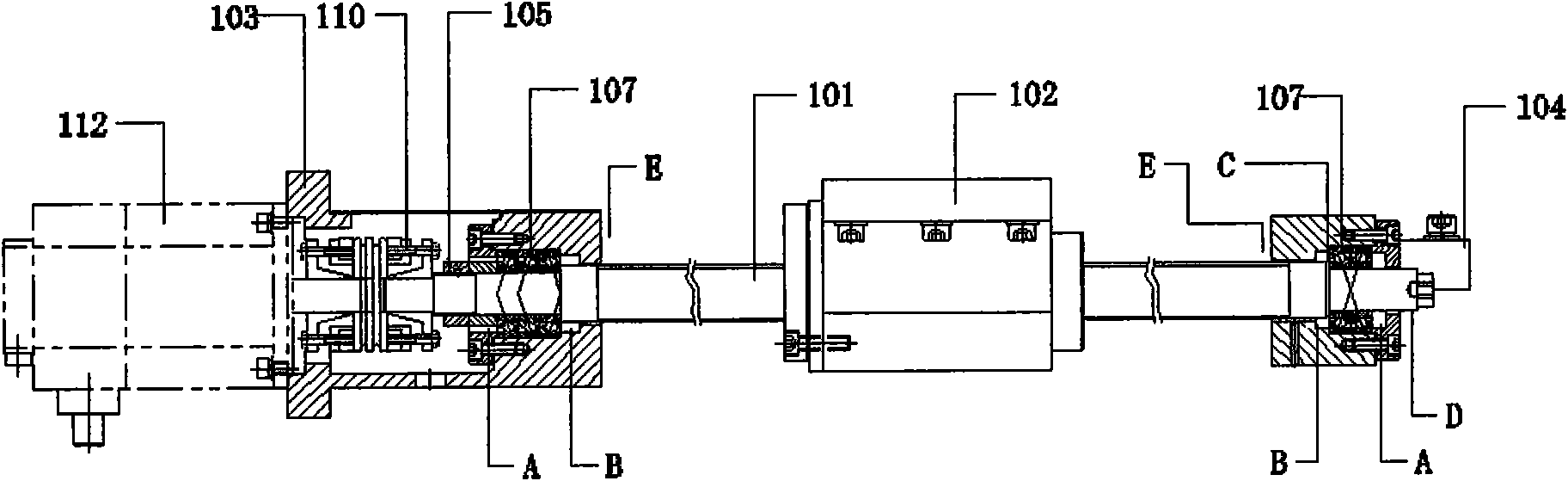

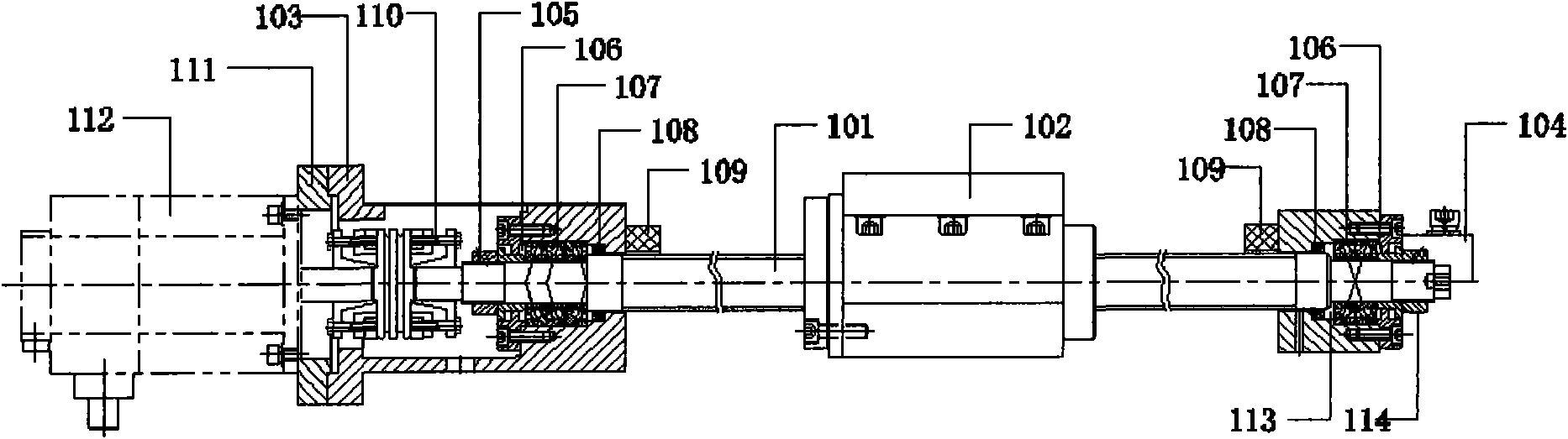

[0015] Depend on image 3 As shown: the present invention includes: ball screw 101, nut seat 102, motor seat 103, bearing seat 104, lock nut 105, two sets of precision bearings 107 supporting both ends of ball screw 101, coupling 110 and servo motor 112 An outer seal 106 and an inner seal 108 are arranged respectively on both sides of the precision bearing 107, and a limit buffer collision block 109 is arranged on the ball screw 101 near the precision bearing 107; at the rear end of the ball screw 101 A gap 113 is reserved at the inner shoulder of the screw; a pre-stretched lock nut 114 is placed at the tail end of the ball screw 101;

[0016] The two sets of precision bearings 107 are respectively a radial thrust ball bearing support in the form of 3 rows of DBD combination at the front end and a radial thrust ball bearing support in the combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com