Locally-reinforced composite dot-matrix sandwich panel and preparation method thereof

A composite material and local reinforcement technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problem of low shear strength and achieve the effect of improving shear strength, increasing strength and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

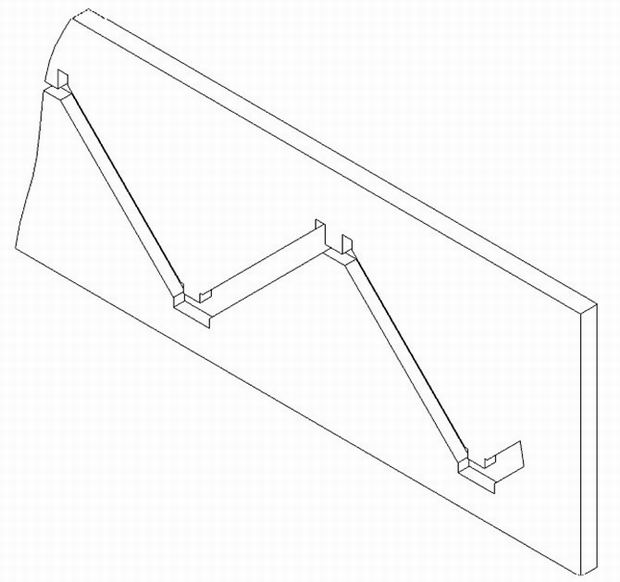

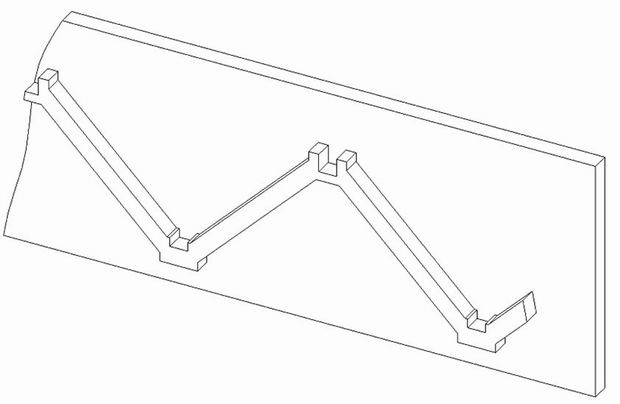

[0016] Specific implementation mode one: the following combination Figure 1 to Figure 7 Describe this embodiment, this embodiment is made up of pyramid lattice core 1, a plurality of reinforcing pieces 2, composite material upper panel 3 and composite material lower panel 4,

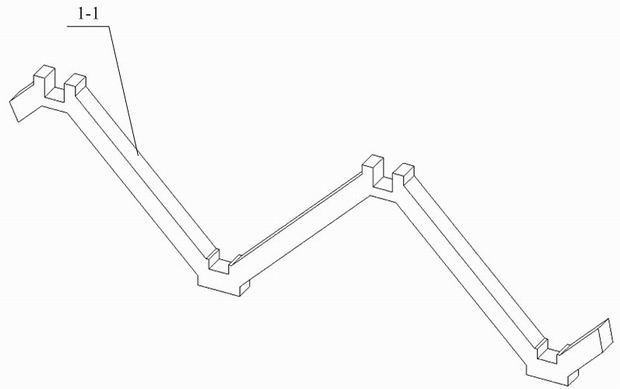

[0017] The pyramid lattice core 1 is composed of a plurality of unidirectional fiber lattice structural monomers 1-1, and each unidirectional fiber lattice structural monomer 1-1 is a continuous W-shaped integral piece composed of four rods. The connection of adjacent rods has a slot structure, and a plurality of unidirectional fiber lattice structure monomers 1-1 interlock each other in a criss-cross pattern through the slot structure to form a pyramid lattice core 1; all two unidirectional fiber points The mutual occlusion of the array structure monomers 1-1 is reinforced by a reinforcing piece 2, and all the reinforcing pieces 2 located at the upper end of the pyramidal lattice core 1 are bonded toge...

specific Embodiment approach 2

[0019] Specific implementation mode two: the following combination Figure 5 This embodiment is described. The difference between this embodiment and Embodiment 1 is that the center of the reinforcement member 2 has a through hole or a blind hole for reinforcement. Other components and connections are the same as those in Embodiment 1.

[0020] When the center of the reinforcement 2 is a through hole, while the composite upper panel 3 and the composite lower panel 4 are bonded to the reinforcement 2, they are also bonded to the two unidirectional fiber lattice structure monomers 1-1 reinforced by the reinforcement 2. 1. The outer surfaces of the joints are bonded at the same time; when the center of the reinforcement 2 is a blind hole, the composite upper panel 3 and the composite lower panel 4 are respectively bonded to the bonding surfaces of the reinforcement 2. The use of the reinforcing member 2 further strengthens the constraint between the unidirectional fiber lattice ...

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the reinforcing member 2 is circular, elliptical, square, rectangular or rhombus. Other compositions and connections are the same as those in the first or second embodiment.

[0022] The shape of the reinforcing piece 2 can be selected according to the needs in actual use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com