Battery pack pressing equipment

A technology of lamination equipment and battery components, applied in the direction of lamination, lamination devices, layered products, etc., can solve the problems of easy deformation and damage of three-fold slide rails, easy to cause work injuries, and uncompact structure, etc., to achieve precise control and The effect of wide adjustment range, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

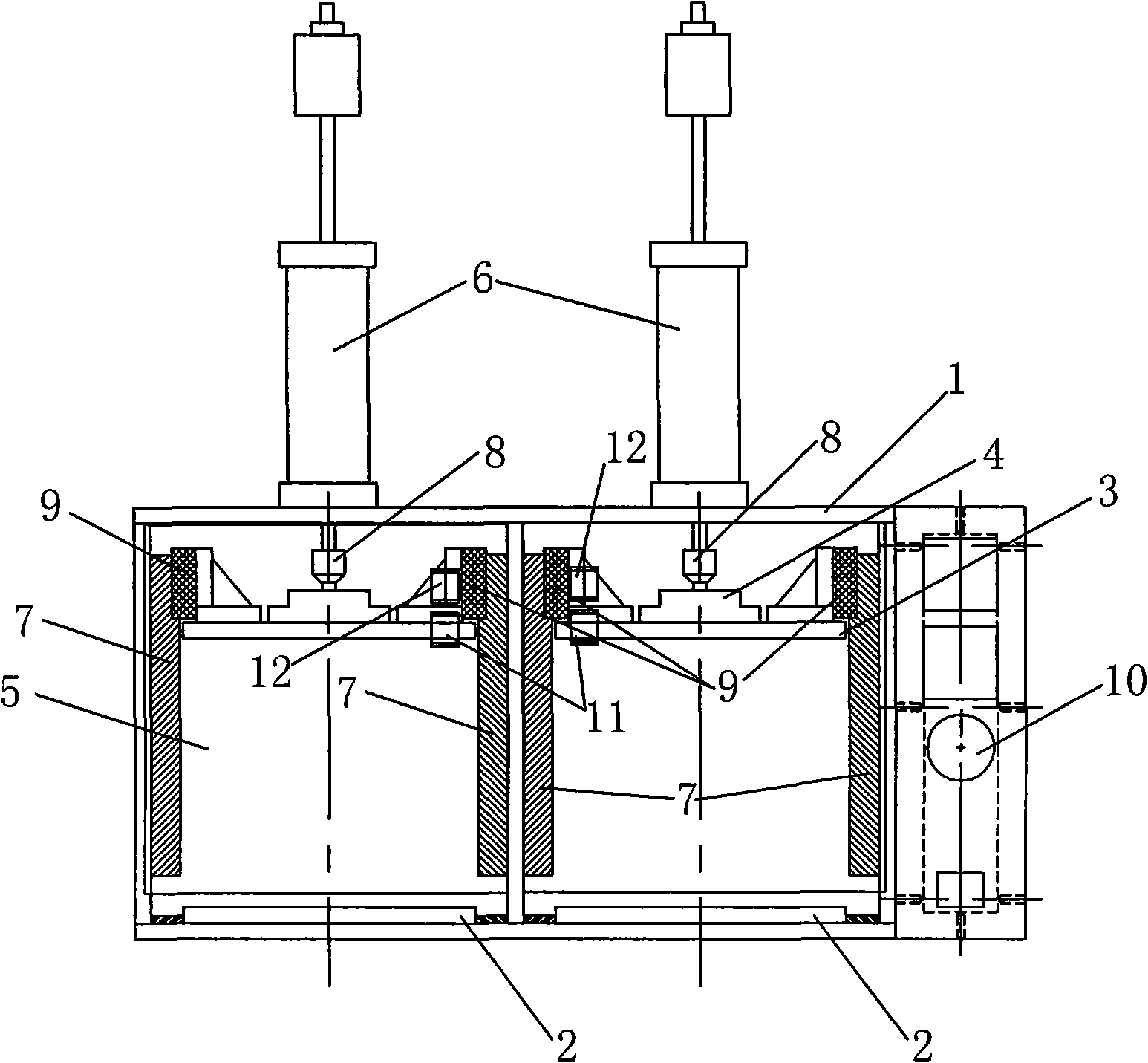

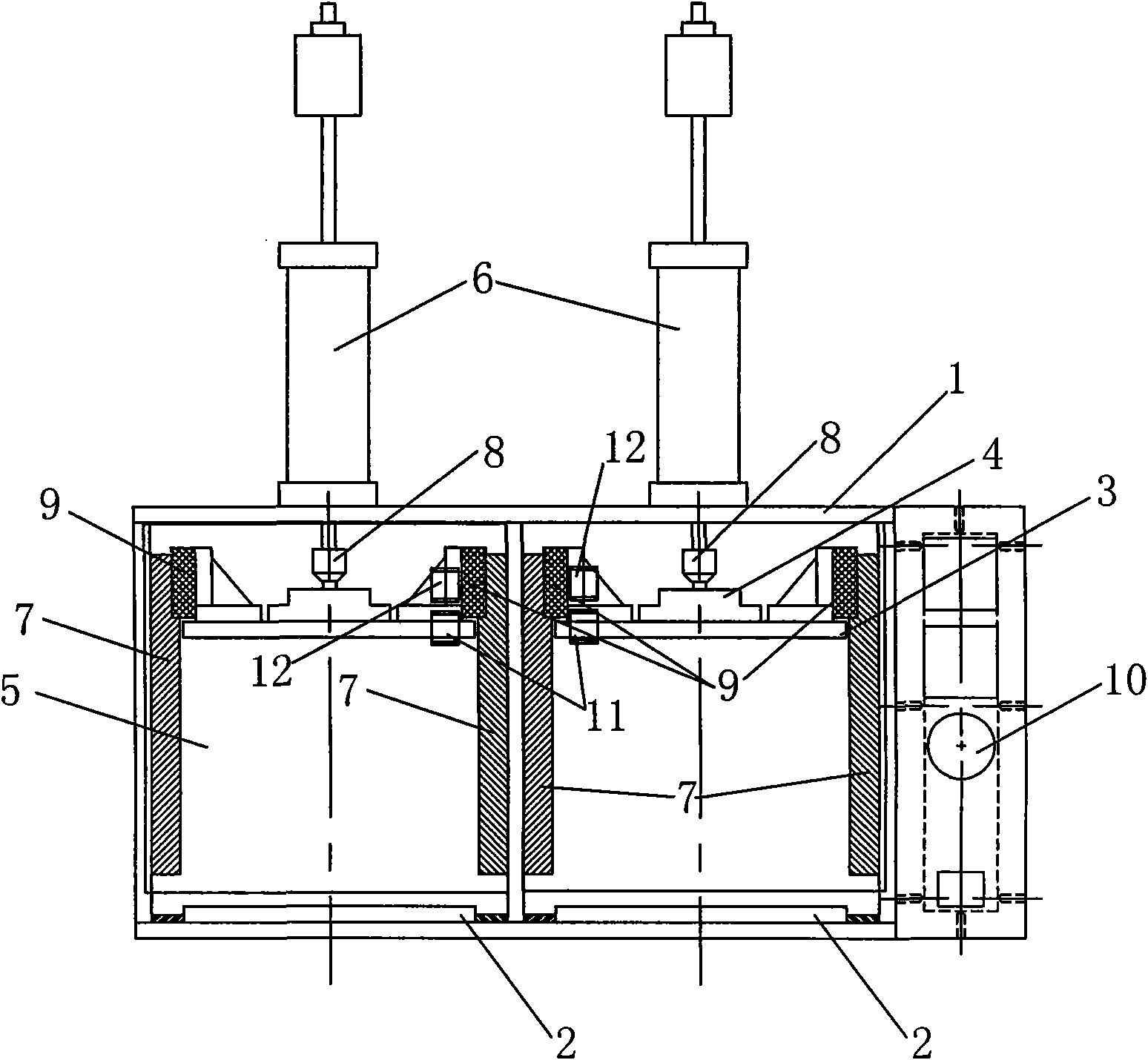

[0015] Such as figure 1 As shown, a battery assembly pressing equipment mainly includes a box body 1, a bottom plate 2, an upper platen 3, a flange plate 4, and a case cover 5. The flange plate 4 is set on the upper platen 3, and the bottom plate 2 is set on the The upper pressing plate 3 is vertically below, and is arranged in the box body 1 together with it, and the box cover 5 is set at the front part of the box body 1; it is characterized in that: the battery assembly pressing equipment is provided with a cylinder 6, and the cylinder 6 is set in the box body On the top of the body 1, the battery assembly pressing equipment is provided with slide rails 7, and the slide rails 7 are arranged on both inner sides of the box body 1;

[0016] The cylinder 6 is an adjustable stroke cylinder, and the bottom of the cylinder 6 is provided with a floating joint 8;

[0017] Described case cover 5 is provided with start switch 11 and emergency stop switch 12;

[0018] The slide rail 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com