Fur dyeing kettle

A fur and pot body technology, applied in the field of fur dyeing pots, can solve the problems of affecting the dyeing operation, steam loss, energy waste, etc., and achieve the effects of saving chemical dyes, simple operation and cost saving.

Inactive Publication Date: 2010-09-22

TONGXIANG NEW ERA FUR

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Existing dyeing of fur all adopts stainless steel monomer without cover dyeing groove. Due to the need to observe the dyeing situation in time, this kind of dyeing groove is all open, and the groove wall is made of single-layer stainless steel material, but in the dyeing process , because the dyeing liquid needs a certain temperature, it is necessary to pass steam into the dyeing liquid to heat it, so that a large amount of heat will evaporate from the open tank along with the water vapor, making the whole dyeing workshop full of steam. , high temperature and steam-filled workshop environment, it is difficult for workers to operate in the workshop; the workshop is full of fog, the ambient air circulation is not smooth, and workers are often scalded due to careless operation. Scratching the groove causes the heat in the groove to be continuously emitted, and the dyeing liquor needs to be heated continuously for a long time to reach the required temperature. The heating speed is slow when the production workers operate, and in the process of continuous evaporation of heat, the dyeing temperature in the pot is more difficult. Steady control makes the operation process busy, and one person cannot take care of multiple grooves at the same time, especially if the heating time is too long, it will cause the product to be burned due to excessive temperature, and cause a large loss of steam and a large waste of energy

Because the dyeing temperature and dyeing time directly affect the dyeing quality, in order to control the dyeing quality as much as possible, it is necessary to observe the dyeing situation with the naked eye. Therefore, almost all dyeing technology experts currently believe that the dyed matter cannot be seen when the groove is covered with heat preservation, and it is impossible Feed, feed, discharge, this is not advisable

Thus, a consensus has been formed in the technical field: think that the fur dyeing device can not be sealed and covered, under the control of this awareness, until now, the fur dyeing grooves are still open, resulting in a large amount of energy consumption , the dyeing quality cannot be guaranteed, and the harsh dyeing environment further affects the dyeing operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

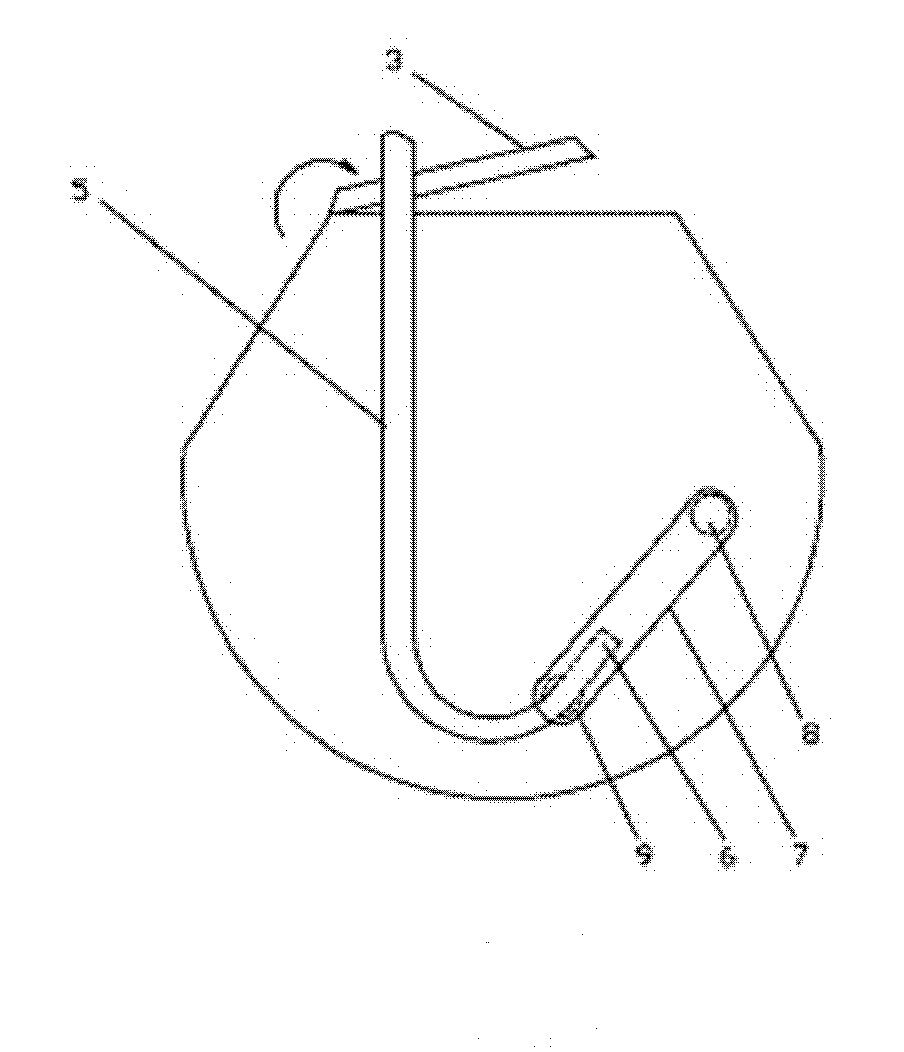

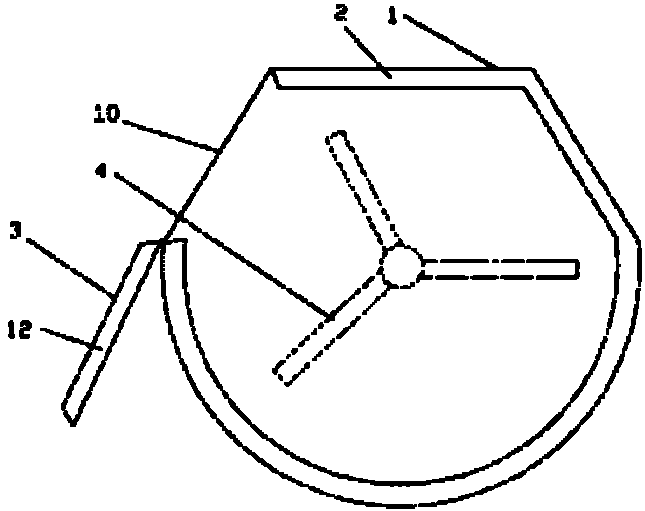

The invention discloses a fur dyeing kettle, comprising a kettle body, a kettle opening and a stirrer device. The fur dyeing kettle is characterized by comprising a thermal barrier; a kettle cover being matched with the kettle opening is arranged on the pot opening and is provided with an insulating layer; the thermal barrier and the insulation layer are in a structure that thermal insulation material is arranged in the middle of stainless steel material on both sides; a backflow pipe is arranged outside one side of the kettle body; the backflow pipe and a port on one side of the kettle body are respectively a backflow liquid inlet and a backflow liquid outlet; and a vapor feed pipe is connected on the backflow pipe. The fur dyeing kettle of the invention has simple workman operation, saves time, labor and cost, and can meet the requirement on economization, beautiful appearance, environmental protection and energy conservation. Compared with the prior art, practical operation proves that vapor, chemical dye and water and power resources are respectively saved more than 50%, more than 15% and more than 10%.

Description

technical field The invention relates to a fur dyeing device, in particular to a fur dyeing pot. Background technique Existing dyeing of fur all adopts stainless steel monomer without cover dyeing groove. Due to the need to observe the dyeing situation in time, this kind of dyeing groove is all open, and the groove wall is made of single-layer stainless steel material, but in the dyeing process , because the dyeing liquid needs a certain temperature, it is necessary to pass steam into the dyeing liquid to heat it, so that a large amount of heat will evaporate from the open tank along with the water vapor, making the whole dyeing workshop full of steam. , high temperature and steam-filled workshop environment, it is difficult for workers to operate in the workshop; the workshop is full of fog, the ambient air circulation is not smooth, and workers are often scalded due to careless operation. Scratching the groove causes the heat in the groove to be continuously emitted, and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06P3/30

Inventor 徐建龙

Owner TONGXIANG NEW ERA FUR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com