Electrothermal copper-smelting slag depleted furnace body

A technology for smelting slag and furnace body, which is applied in the field of electrothermal depletion furnace body of copper smelting slag, can solve the problems of long process flow and large floor space, and achieve the advantages of reducing cost, reducing power consumption, reducing power consumption and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

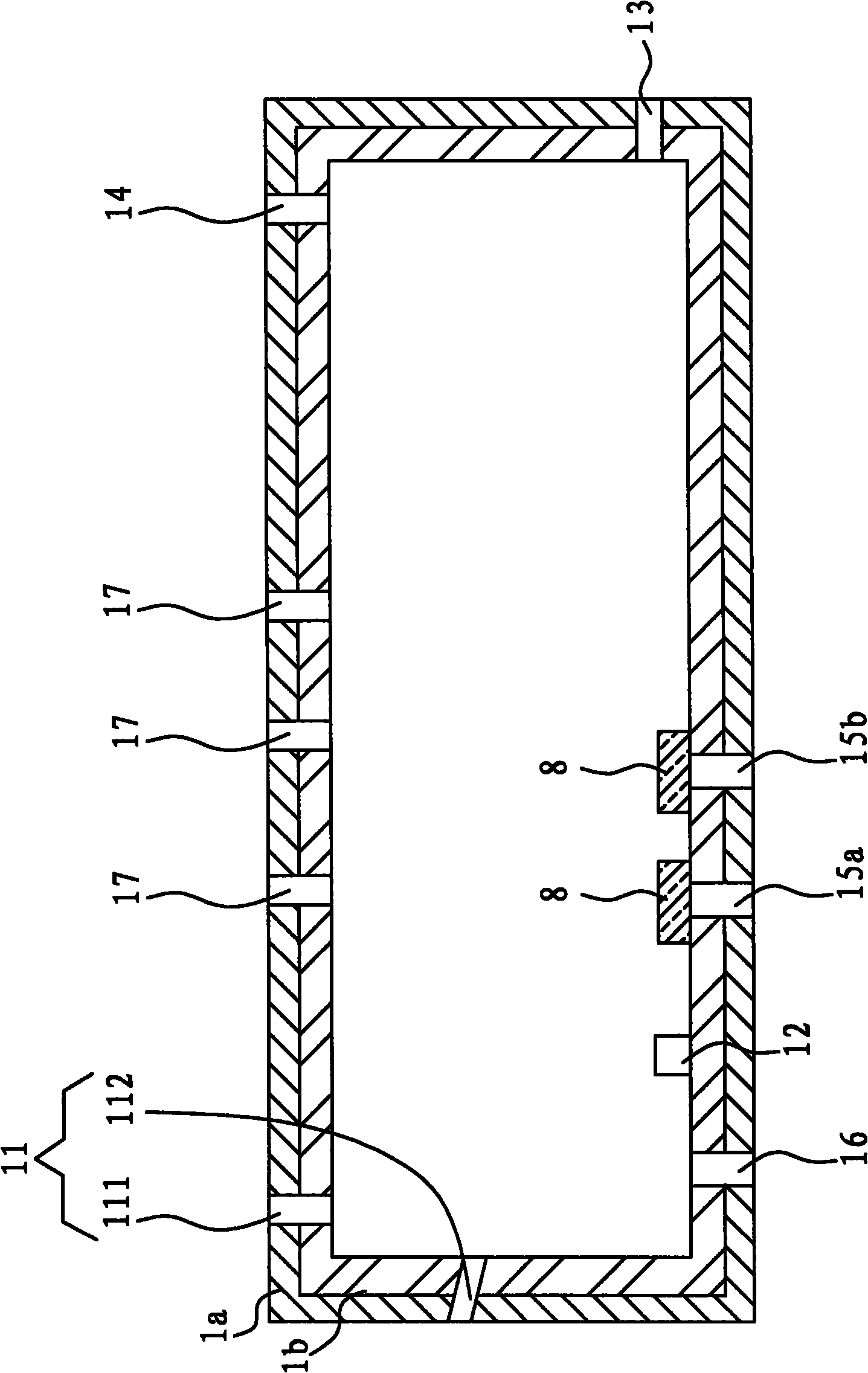

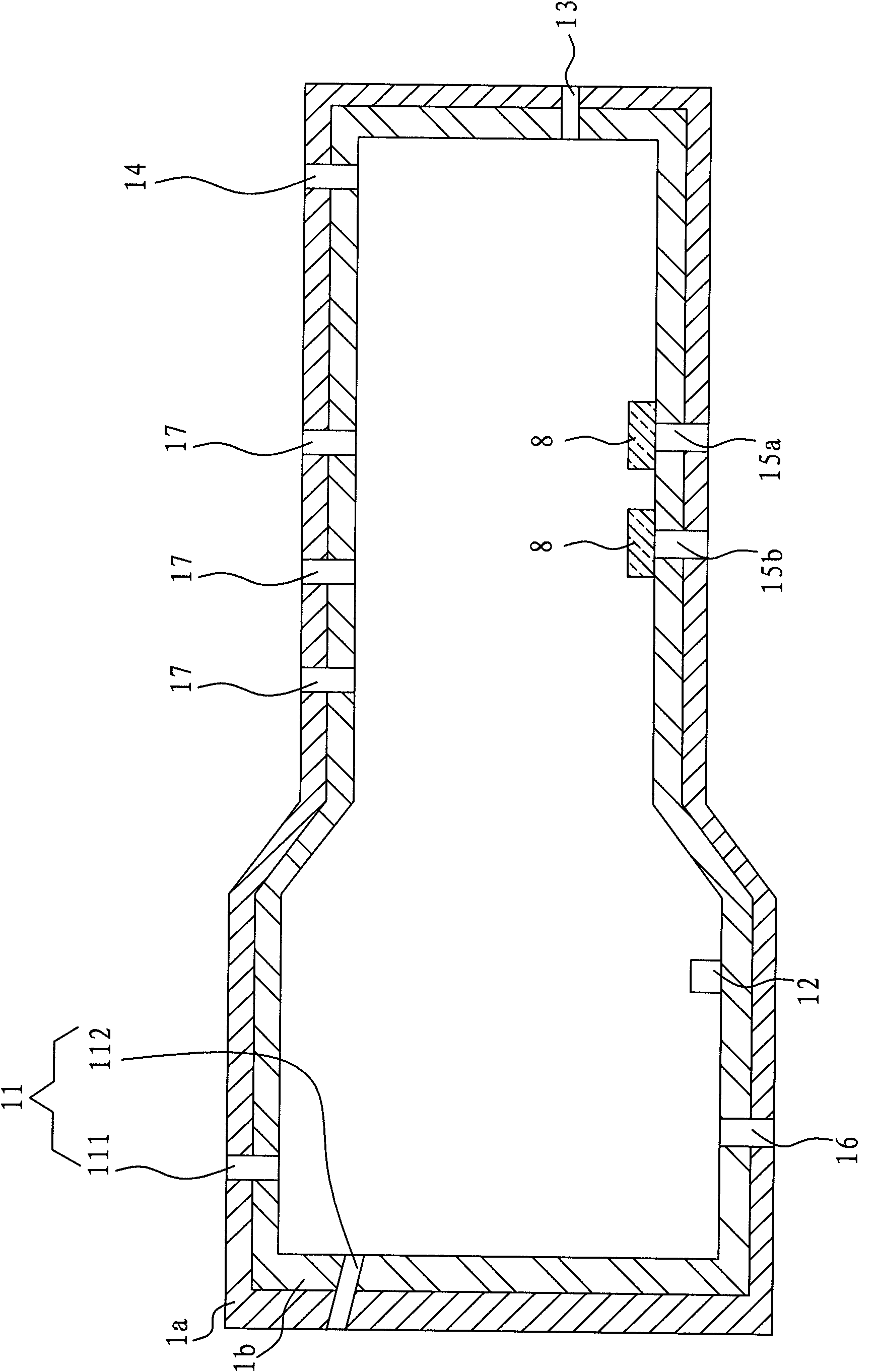

[0038] Refer below figure 1 with 2 The furnace body 1 of an electrothermal depletion furnace for copper smelting slag according to an embodiment of the present invention is described.

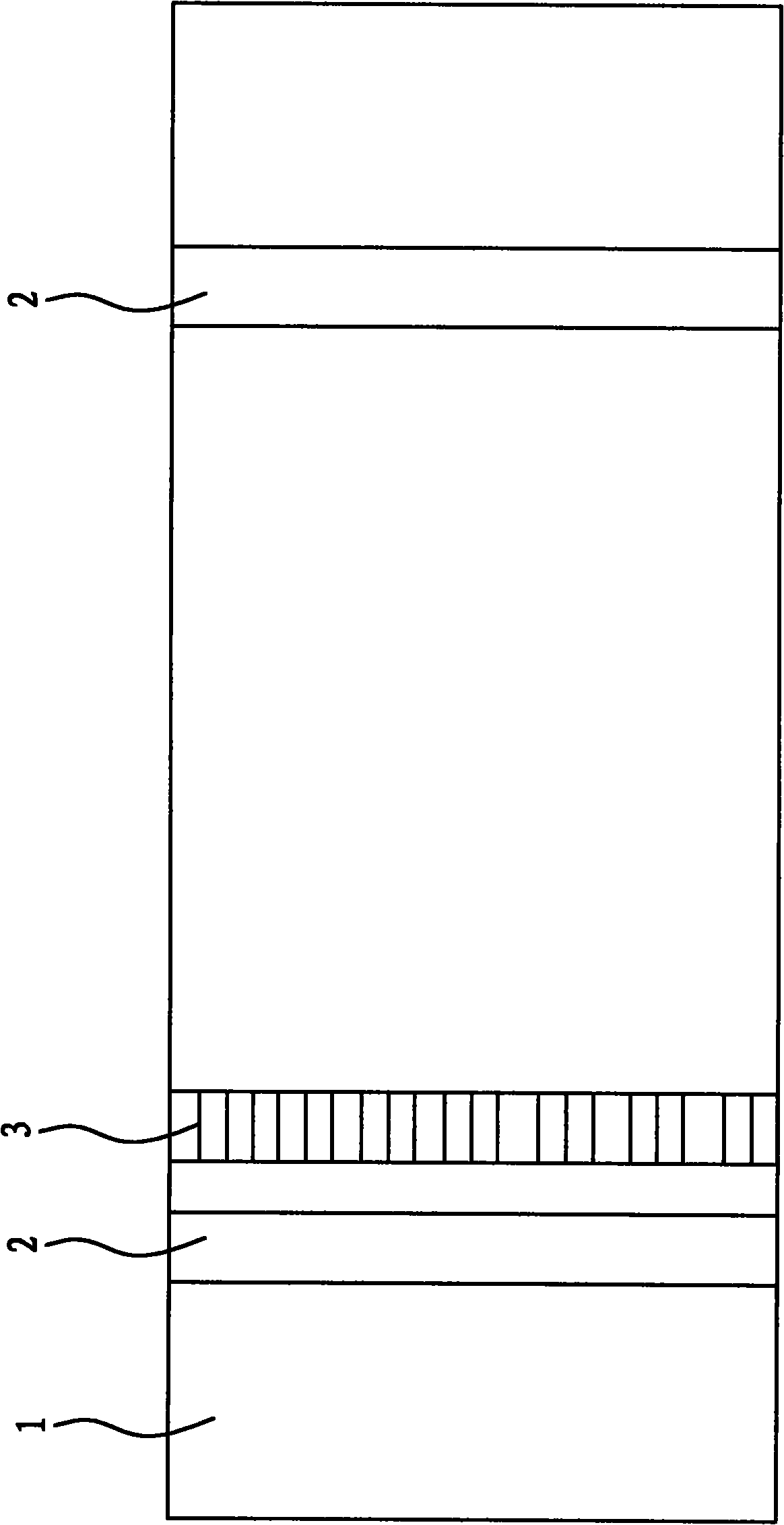

[0039] exist figure 1 with 2 In the example shown, the furnace body 1 of the electrothermal depletion furnace for copper smelting slag is a horizontal cylindrical vessel, but the present invention is not limited thereto. The furnace body 1 includes a furnace shell 1a defining a furnace, and a refractory material layer 1b provided on the inner wall of the furnace shell 1a. The body of furnace 1 is formed with a charging port 11, a siphon port 12, a slag discharge port 13, an electrode socket 17, a smoke exhaust port 14, and an oxygen lance socket 16 formed at the bottom of the furnace shell 1a.

[0040] Ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com