Combined type impeller, manufacturing method and aerator manufactured by using same

A composite, aerator technology, applied in the direction of chemical instruments and methods, applications, water aeration, etc., can solve the problems of fish and shrimp stuck, water cannot flow effectively, and affect the oxygenation capacity of the aerator, etc., to achieve High oxygen increasing capacity, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

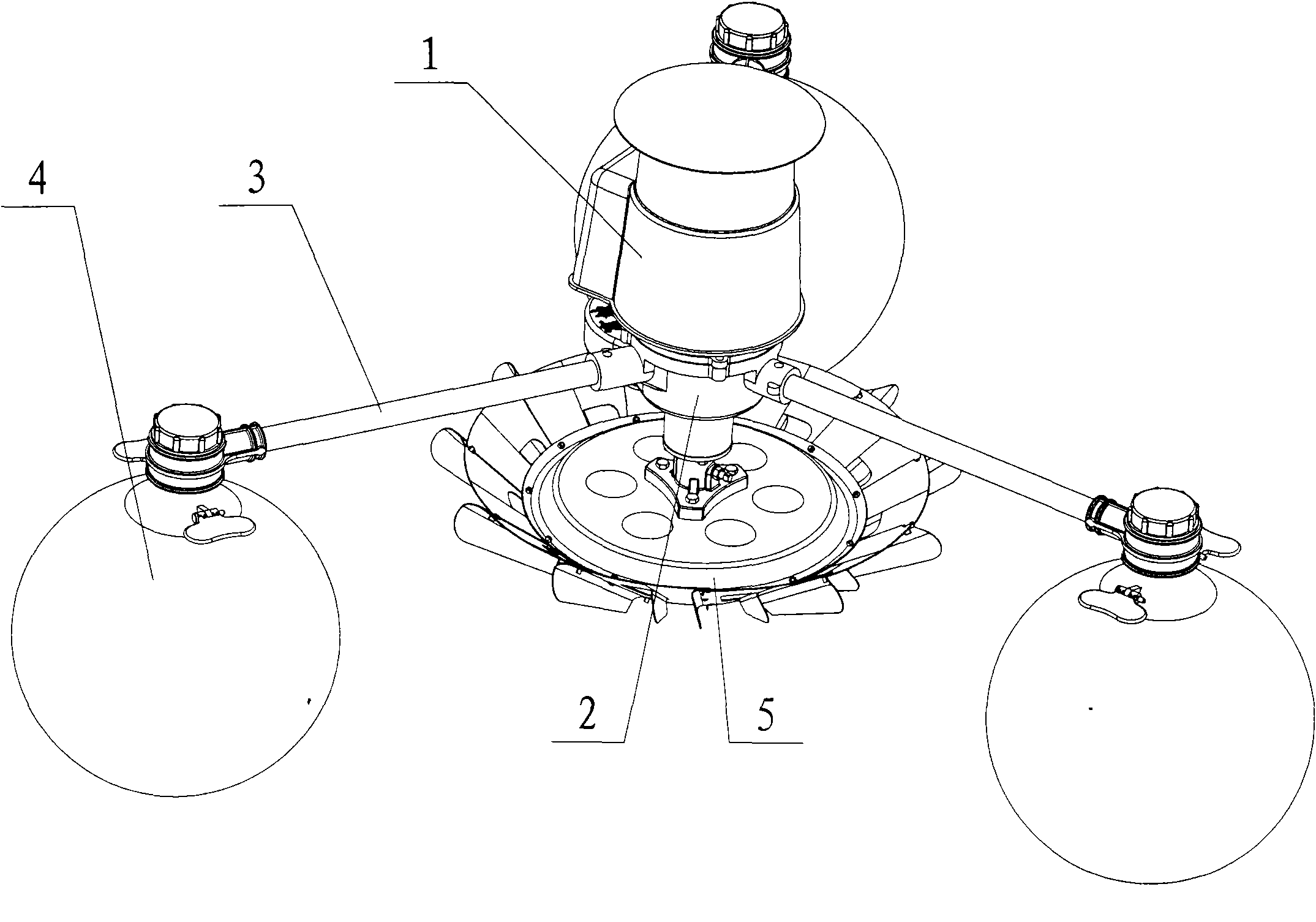

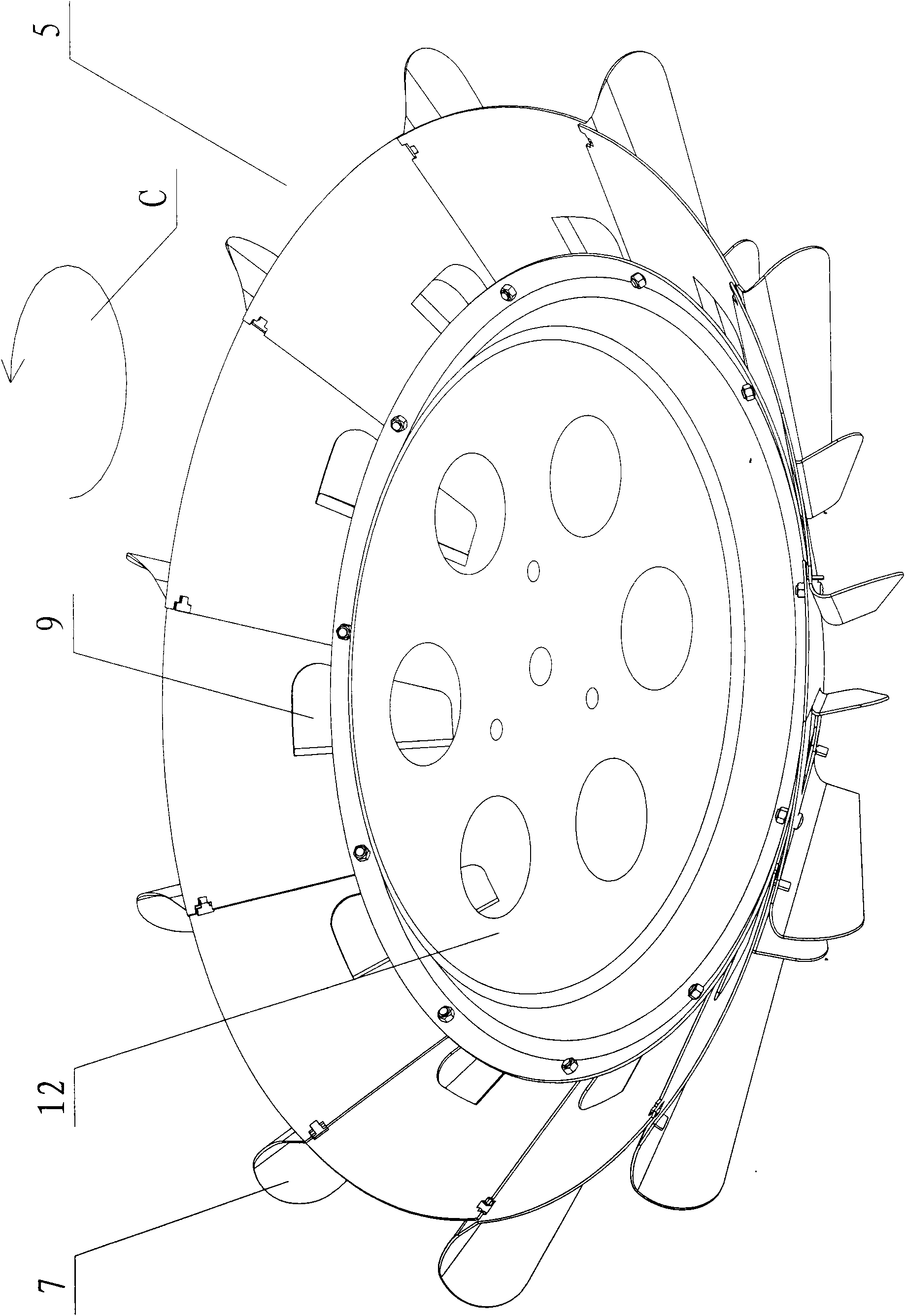

[0030] Below with specific embodiment the utility model is described further, see Figure 1-7 :

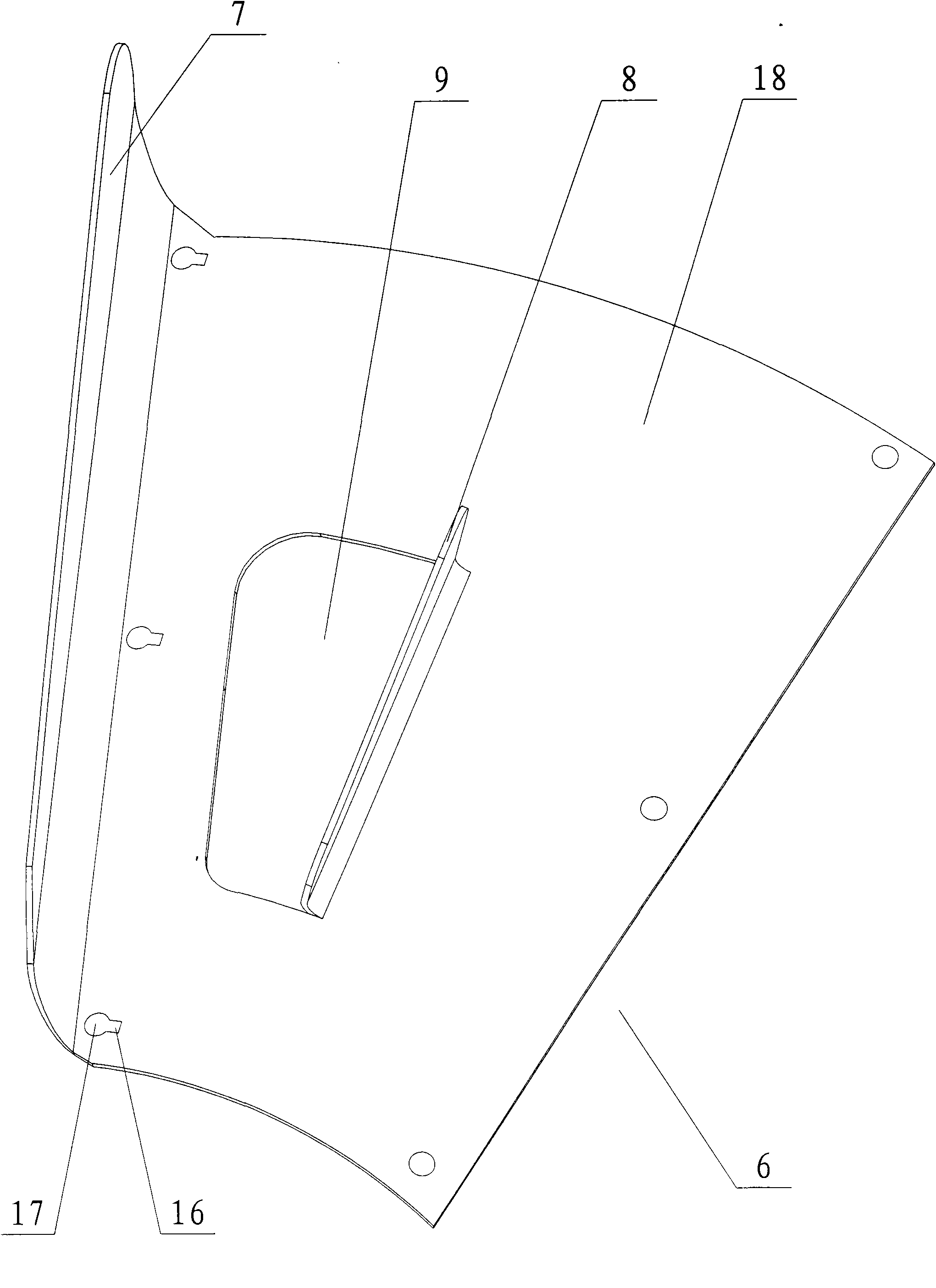

[0031] Composite impeller, a plurality of single impeller blades 6 are combined with each other and connected with the support disc 12 to form an annular composite impeller 5, the single impeller blade 6: is set on one side of each fan-shaped wheel housing 18 There are large blades 7, and a water-passing window 9 is provided in the middle of each fan-shaped wheel housing 18, and small blades are arranged on the same direction as the large blade 7 on the side of each fan-shaped wheel housing 18 away from the window 9 of the large blade 7 8. The interlocking is that the buckle or buckle groove 16 provided on the front side of a sector-shaped wheel shell 18 is fastened to the buckle groove or buckle 10 provided on the rear side of the adjacent sector-shaped wheel shell 18 .

[0032] At least one small vane 8 and a water-passing window 9 are respectively arranged on each fan-shaped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com