Composition of fexofenadine hydrochloride and microcrystalline cellulose and preparation method thereof

A technology of fexofenadine hydrochloride and microcrystalline cellulose is applied in the field of fexofenadine hydrochloride and microcrystalline cellulose composition and preparation thereof, and achieves good clinical effect, good fluidity and compressibility, good Effects of disintegration and compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

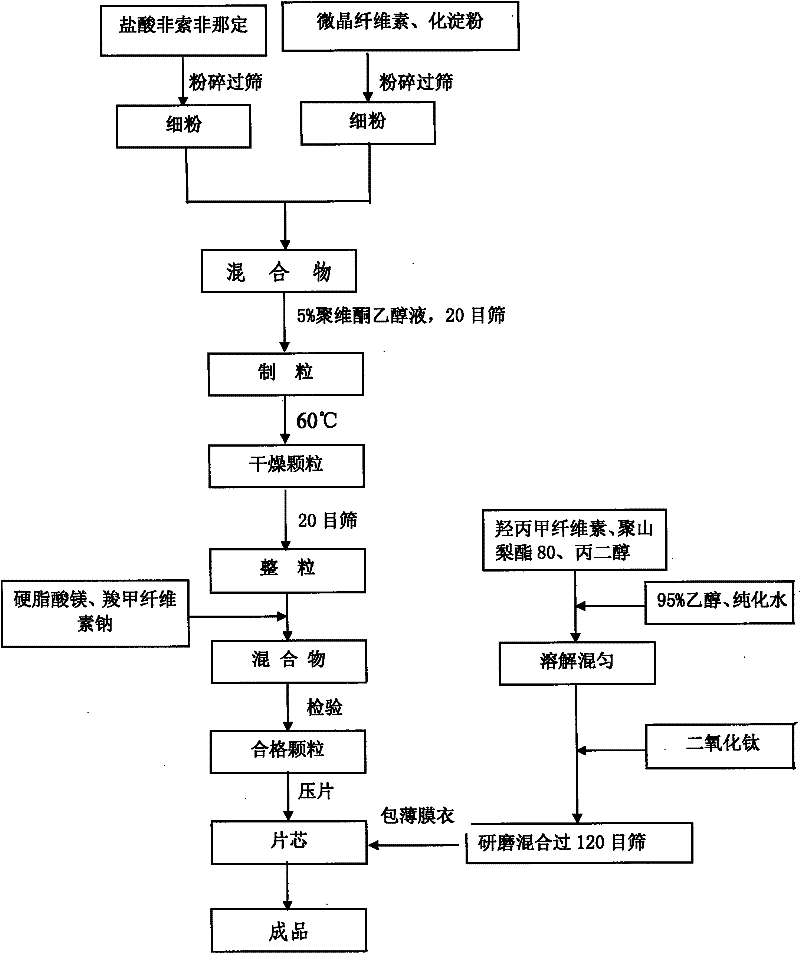

[0024] Referring to accompanying drawing, the present invention relates to a kind of combination medicine of fexofenadine hydrochloride and microcrystalline cellulose, it is characterized in that, described medicine has by making 1000 cores altogether:

[0025] 60g of fexofenadine hydrochloride, 66g of microcrystalline cellulose, 34g of starch, 10g of sodium carmellose, appropriate amount of 5% ethanol solution of povidone, 0.8g of magnesium stearate;

[0026] Pack 1000 film coats in total: hypromellose 0.67g, propylene glycol 0.33ml, polysorbate 800.33ml, titanium dioxide 0.67g, 95% ethanol 26.7ml, purified water 6.67ml.

[0027] Preferably, the medicine has 50 tablet cores: fexofenadine hydrochloride 3.00g, microcrystalline cellulose 4.75g, carmellose sodium 0.44g, magnesium stearate 0.04g, 5% povidone Appropriate amount of ethanol solution.

[0028] Preferably, the medicine has 50 cores made in total: 3.00 g of fexofenadine hydrochloride, 4.45 g of microcrystalline cellulo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com