Low-temperature preparation method of highly oriented single crystal titanium dioxide nanowire array film

A nanowire array and titanium dioxide technology, which is applied in the field of low-temperature preparation of semiconductor nanowire array films, can solve the problems of nanotube length limitation, unfavorable large-scale production, and affecting lighting methods, etc., to achieve low raw material costs and easy large-scale film formation , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

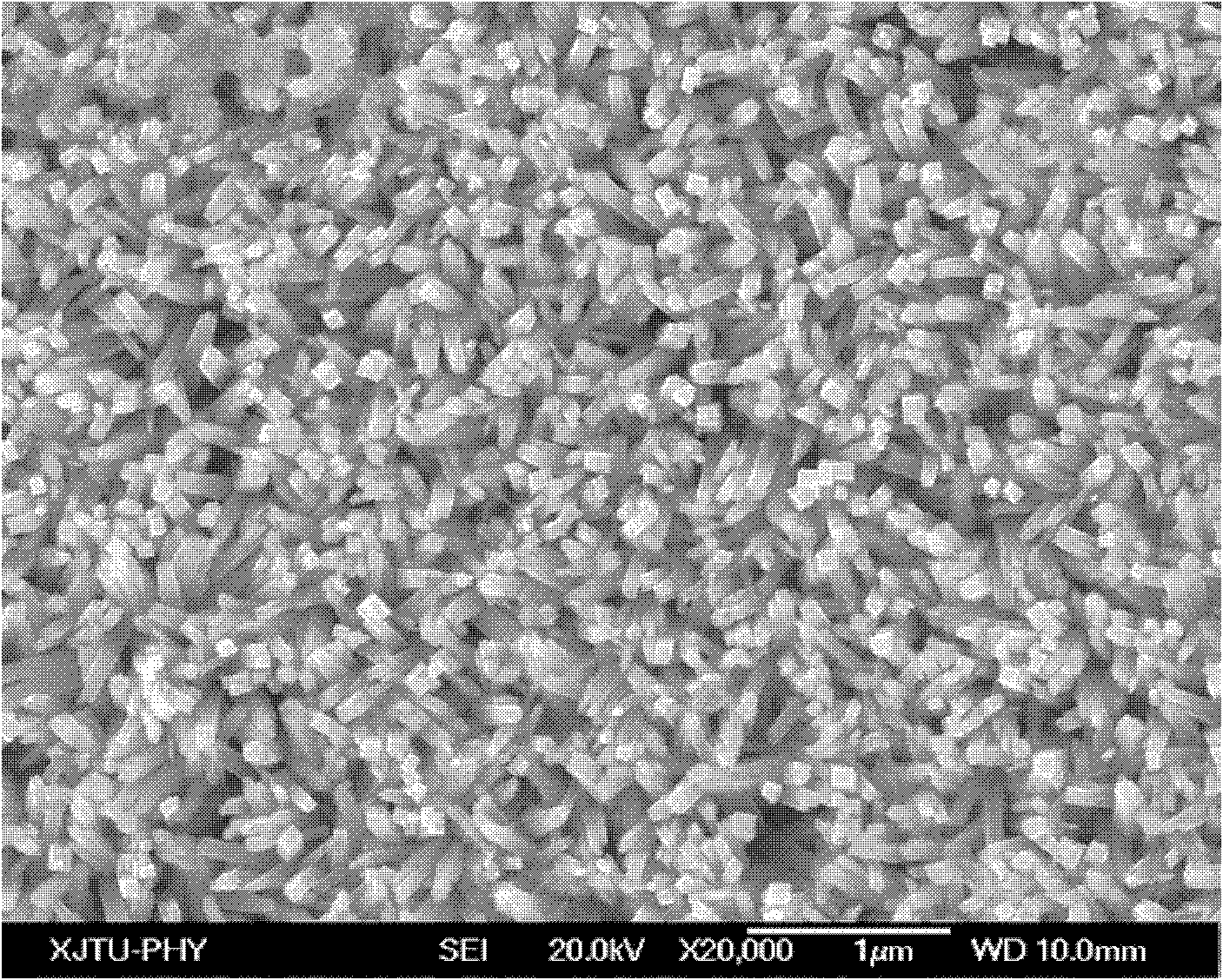

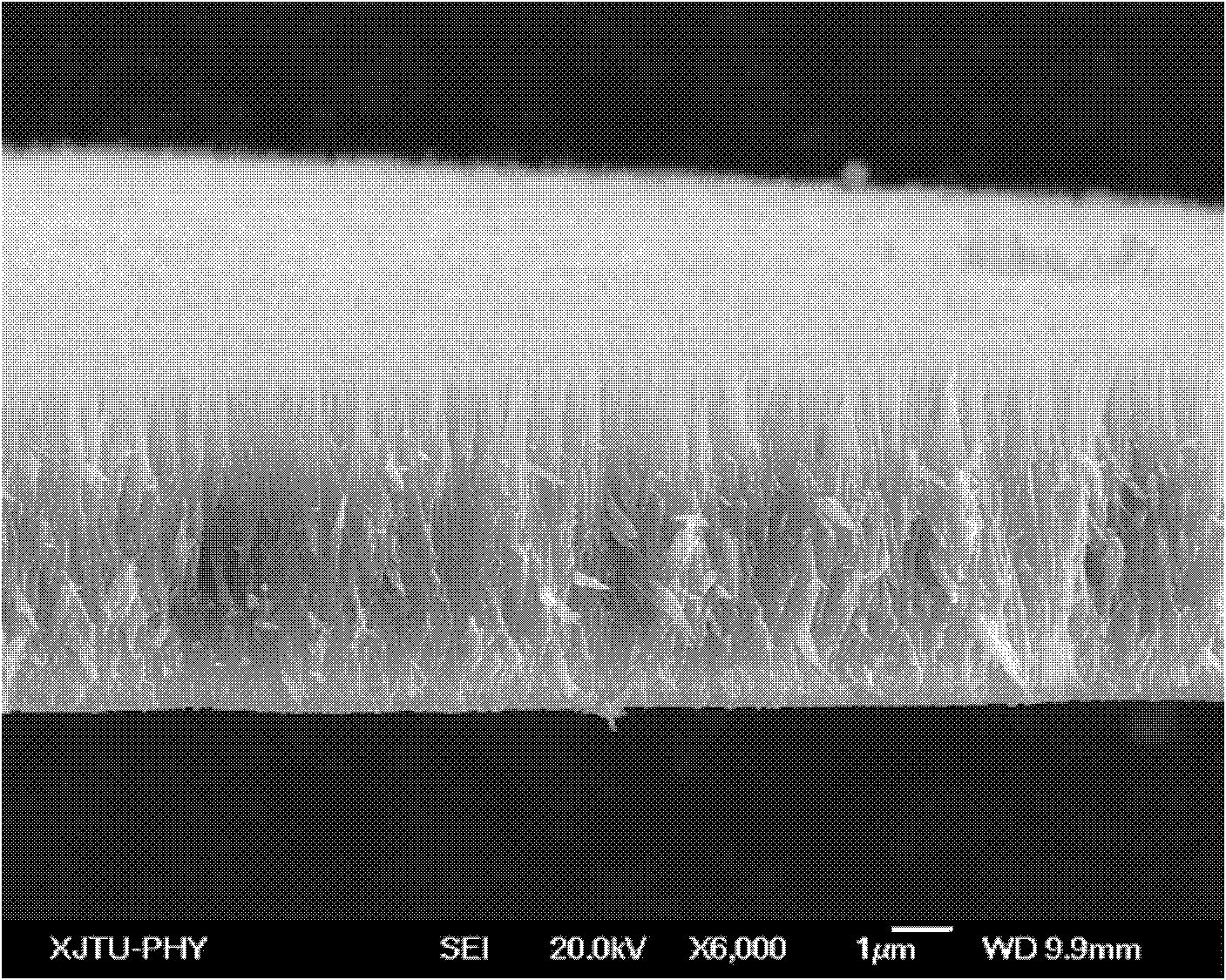

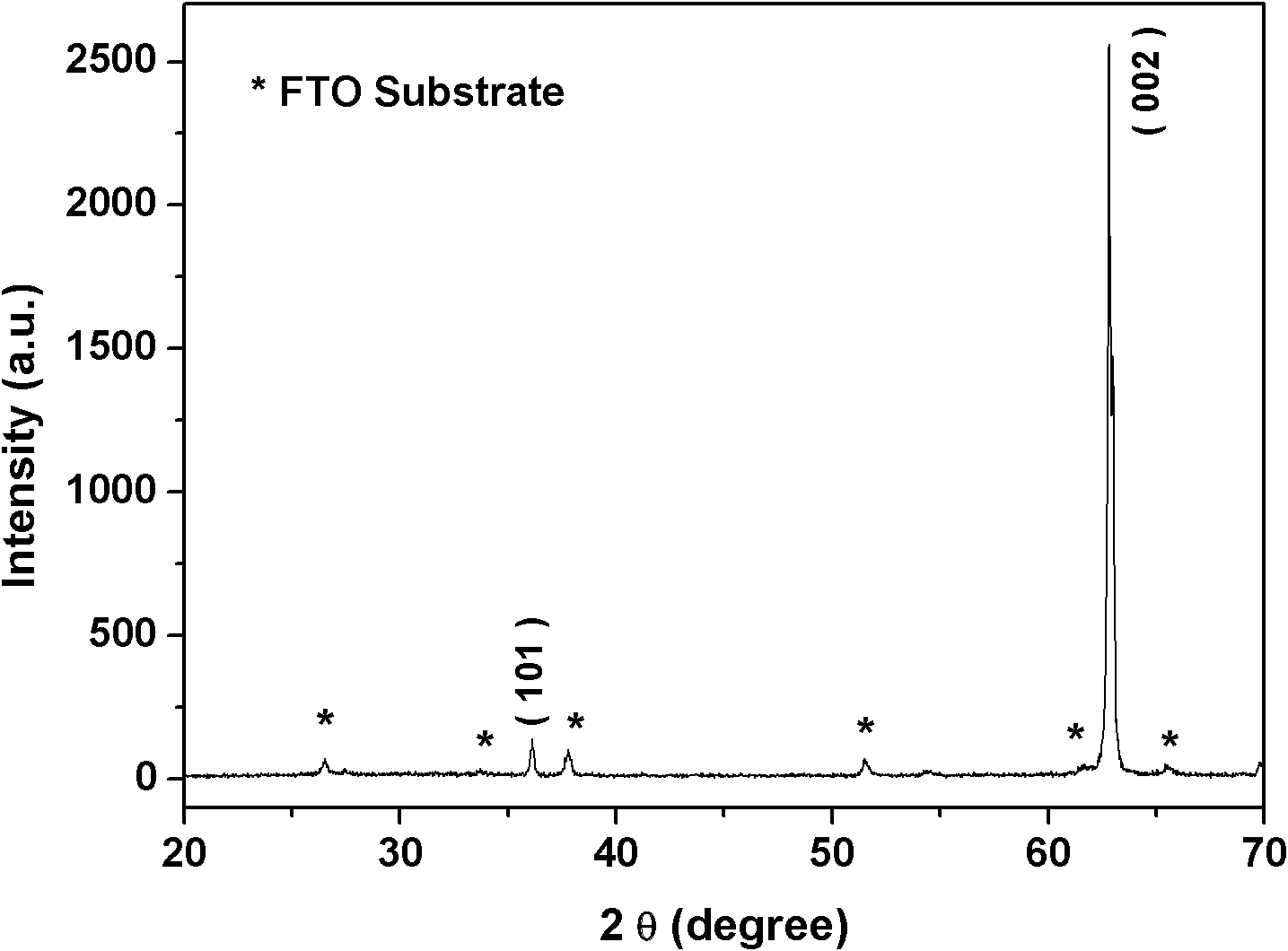

[0011] Example 1: 1) First, cut the fluorine-doped tin oxide conductive glass (FTO) into a size of 1.5cm × 2.0, and then ultrasonically clean it with acetone, ethanol and deionized water and dry it, then put the fluorine-doped tin oxide conductive glass Put it into the polytetrafluoroethylene lining of the stainless steel autoclave, mix toluene, butyl titanate and concentrated hydrochloric acid with a concentration of 36-38% according to the volume ratio of 10:0.5:0.5, and then add it to the polytetrafluoroethylene lining of the stainless steel autoclave 2) Next, transfer the sealed autoclave to constant temperature equipment, and keep it warm for 20 hours at a constant temperature of 160°C for solvothermal reaction. After the reaction, it is naturally cooled to Room temperature; 3) Then, open the lid of the autoclave, take out the fluorine-doped tin oxide conductive glass, fully rinse the fluorine-doped tin oxide conductive glass with absolute ethanol and isopropanol, and dry ...

Embodiment 2

[0012] Example 2: 1) First, cut the fluorine-doped tin oxide conductive glass (FTO) into a size of 1.5cm × 2.0, and then ultrasonically clean it with acetone, ethanol and deionized water and dry it, then put the fluorine-doped tin oxide conductive glass Put it into the polytetrafluoroethylene lining of the stainless steel autoclave, mix toluene, butyl titanate and concentrated hydrochloric acid with a concentration of 36-38% according to the volume ratio of 10:0.5:0.5, and then add it to the polytetrafluoroethylene lining of the stainless steel autoclave Seal the autoclave in an ethylene liner; 2) Next, transfer the sealed autoclave to a constant temperature device, keep it warm for 10 hours at a constant temperature of 180°C, and carry out a solvothermal reaction. After the reaction is completed, naturally cool to room temperature 3) Then, open the autoclave cover, take out the fluorine-doped tin oxide conductive glass and adopt an ultrasonic bath to remove the residue on the ...

Embodiment 3

[0013] Example 3: 1) First, cut the fluorine-doped tin oxide conductive glass (FTO) into a size of 1.5cm × 2.0, and then ultrasonically clean it with acetone, ethanol and deionized water and dry it, then put the fluorine-doped tin oxide conductive glass Put it into the polytetrafluoroethylene lining of the stainless steel autoclave, mix toluene, butyl titanate and concentrated hydrochloric acid with a concentration of 36-38% according to the volume ratio of 10:0.8:1.0, and then add it to the polytetrafluoroethylene lining of the stainless steel autoclave Seal the autoclave in an ethylene liner; 2) Next, transfer the sealed autoclave to a constant temperature device, keep it warm for 10 hours at a constant temperature of 180°C, and carry out a solvothermal reaction. After the reaction is completed, naturally cool to room temperature ; 3) Then, open the autoclave cover, take out the fluorine-doped tin oxide conductive glass, fully rinse the residue on the conductive surface of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap