Gate valve device

A gate valve and spool technology applied in the field of gate valve devices to achieve the effect of easy power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

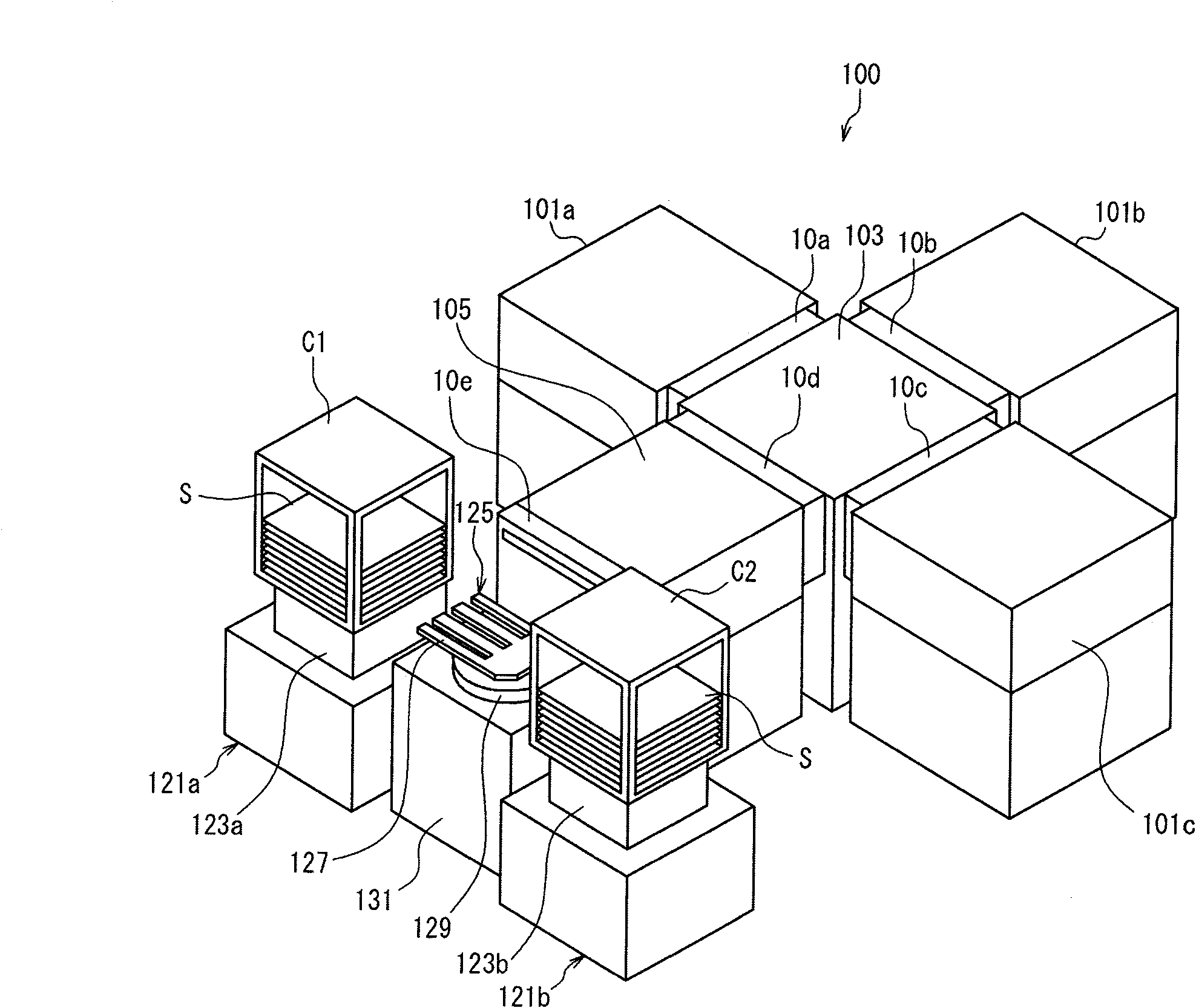

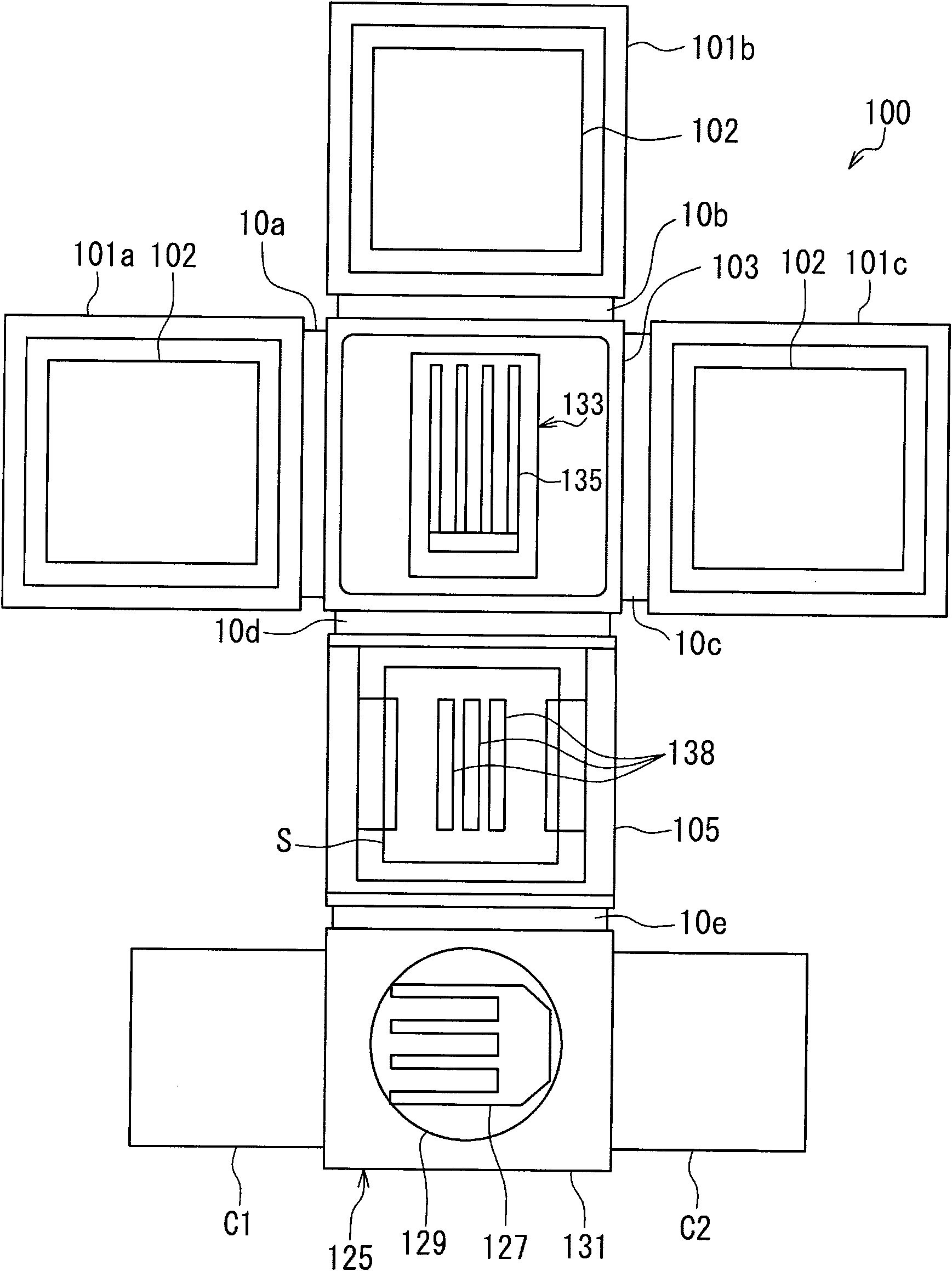

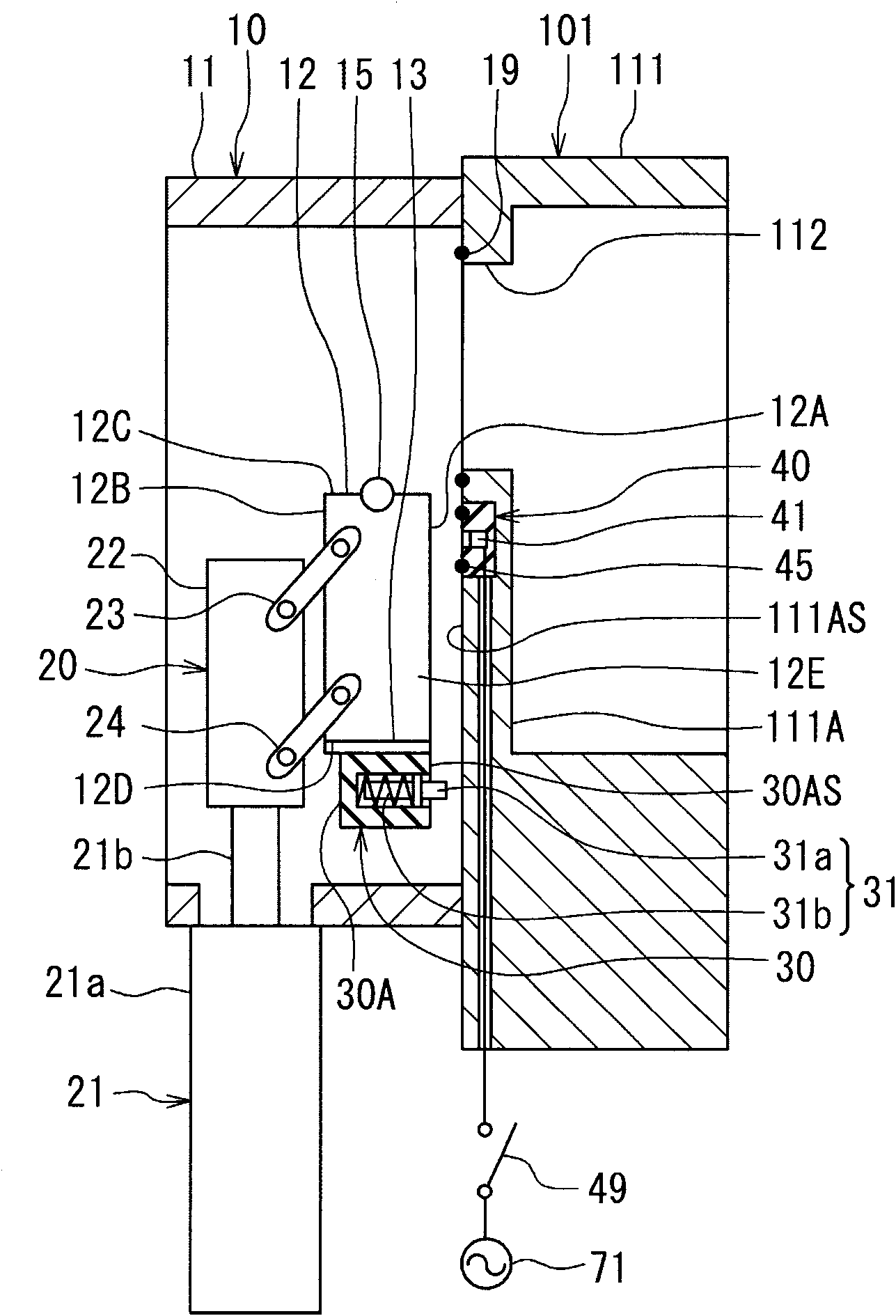

[0040] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. First, refer to figure 1 and figure 2 , the configuration of a vacuum processing system 100 as an example of a system including the gate valve device according to the first embodiment of the present invention will be described. figure 1 It is a perspective view schematically showing the vacuum processing system 100 . figure 2 It is a top view schematically showing the inside of the vacuum processing system 100 . The vacuum processing system 100 is configured, for example, as a processing system for performing plasma processing on a glass substrate (hereinafter simply referred to as "substrate") S for FPD. Moreover, as FPD, a liquid crystal display (LCD), an electroluminescence (Electro Luminescence; EL) display, a plasma display panel (PDP), etc. are mentioned.

[0041] The vacuum processing system 100 has five vacuum chambers connected in a cross shape. ...

no. 2 Embodiment approach

[0102] Below, refer to Figure 10 ~ Figure 12 , and a gate valve device according to a second embodiment of the present invention will be described. Figure 10 ~ Figure 12 It is a sectional view showing the structure of the gate valve device of this embodiment. in addition, Figure 10 Indicates the open state of the gate valve device, Figure 11 and Figure 12 Indicates the closed state of the gate valve device.

[0103] Differences between the gate valve device 80 of this embodiment and the gate valve device 10 of the first embodiment will be described below. The gate valve device 80 has a housing 81 instead of the housing 11 of the gate valve device 10 . The casing 81 has a box shape having an upper portion, a bottom portion, and four side portions connecting the upper portion and the bottom portion. One of the four side portions of the housing 81 is in contact with the wall 111A of the housing 111 of the chamber 101 . This side portion is referred to as a wall consti...

no. 3 Embodiment approach

[0116] Below, refer to Figure 13 ~ Figure 17 , and a gate valve device according to a third embodiment of the present invention will be described. Figure 13 ~ Figure 15 It is a sectional view showing the structure of the gate valve device of this embodiment. in addition, Figure 13 Indicates the open state of the gate valve device, Figure 14 and Figure 15 Indicates the closed state of the gate valve device. Figure 16 yes means Figure 14 It is a front view of the valve body, the heater, the connector part, the sub-connector part and the sub-terminal part of the gate valve device in the state shown. Figure 17 It is a circuit diagram showing the circuit configuration of the gate valve device of this embodiment.

[0117] The gate valve device 90 of the present embodiment includes a sub-connector part 50 and a sub-terminal part 60 in addition to the constituent elements of the gate valve device 10 of the first embodiment. The sub connector part 50 is integrated with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com