Single-working medium pressure-bearing circulated layered heat-storage split solar water heater with glass heat collecting pipes

A technology of solar water heaters and glass heat collecting tubes, applied in the field of solar thermal energy utilization, can solve the problems of low heat collecting efficiency of heat collecting tubes, failure to withstand pressure, and no antifreeze, etc., and achieve the effect of improving heat collection efficiency and significant temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

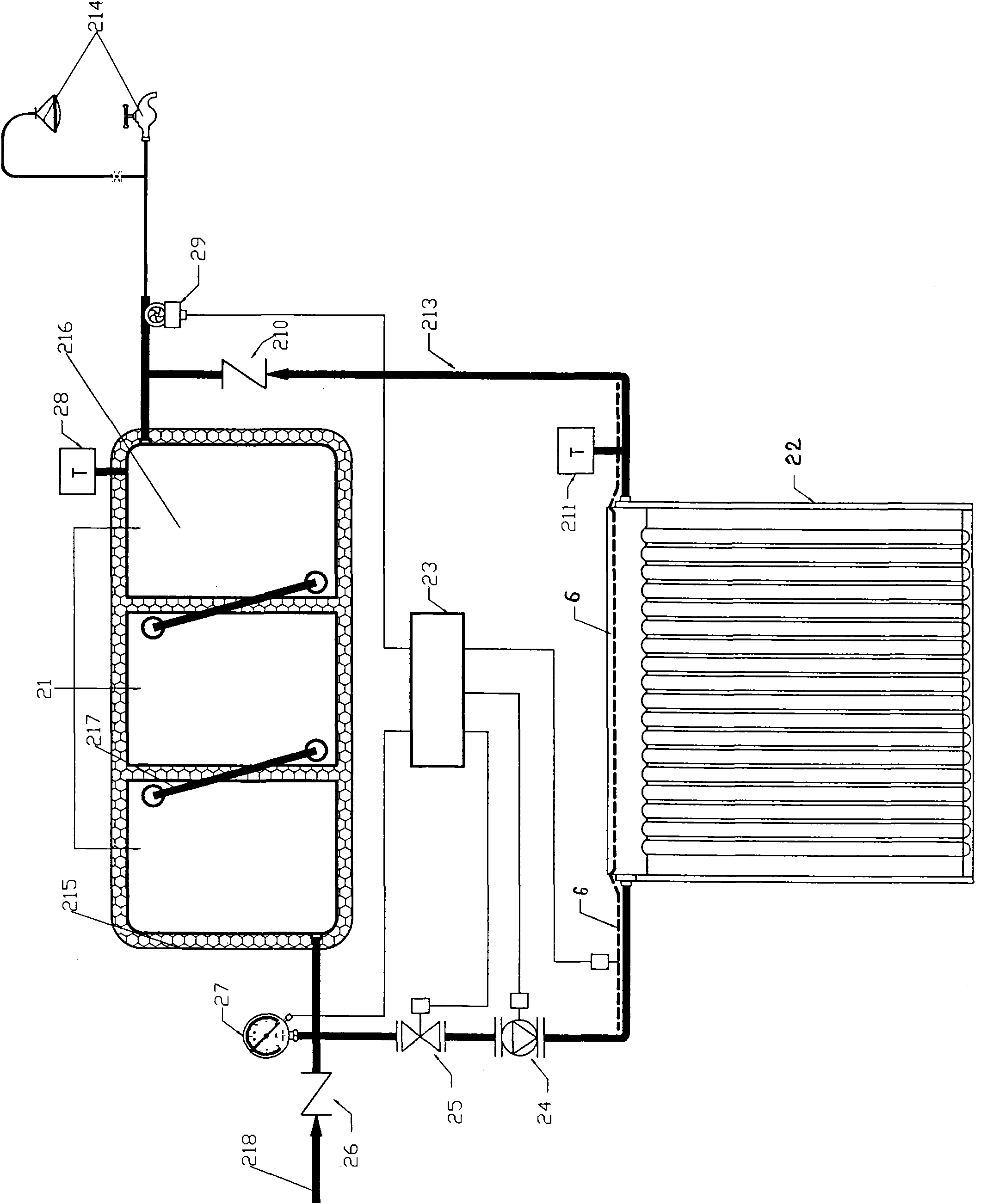

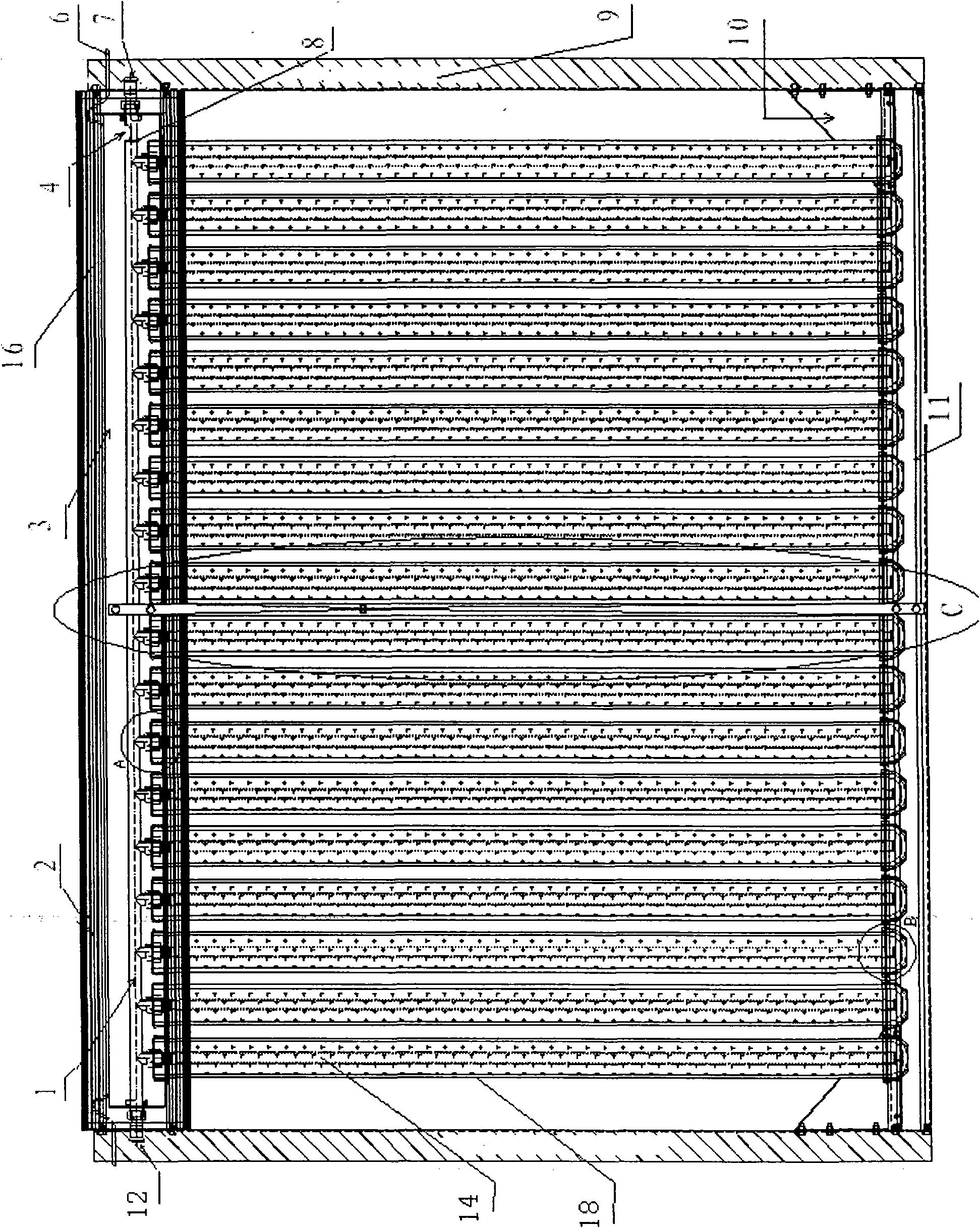

[0027] A kind of glass heat-collecting tube single working medium pressurized cycle layered thermal storage split solar water heater, such as figure 1 Shown includes water inlet check valve 26, temperature sensor, water outlet check valve 210, solar heat collector 22, glass heat collector tube, single working medium, pressurized cycle, layered heat storage split solar water heater, and layered heat storage tank 21. Explosion-proof pressure gauge 27, circulating pump 29, tap water pipe 218 is connected to one end of the four-way connecting pipe through the water inlet check valve 26, and one end of the four-way connecting pipe is connected to the layered heat storage tank 21 through the pipe, and the four-way connection One end of the pipe is connected to an explosion-proof pressure gauge, and one end of the four-way connection pipe is connected to the cold water working medium inlet of the solar heat collection module through the pipeline through the solenoid valve 25 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com