Cup-shaped harmonic oscillator of cup-shaped fluctuated gyroscope and mechanical balancing method thereof

A technology of mechanical balance and harmonic oscillator, which is applied in the direction of speed measurement by gyro effect, gyroscope/steering sensing equipment, measuring device, etc. It can solve the problems of extremely high requirements for shape modification equipment, single shape modification means, and poor economy. , to achieve the effect of improving the modification efficiency, flexible operation and high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

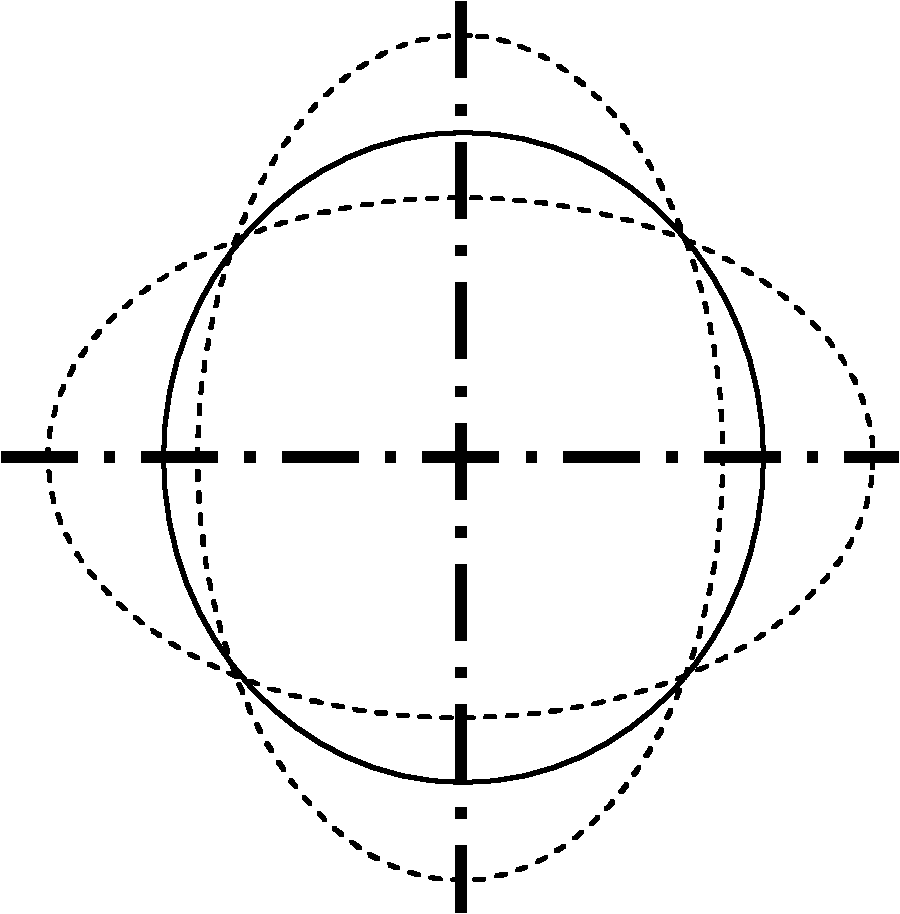

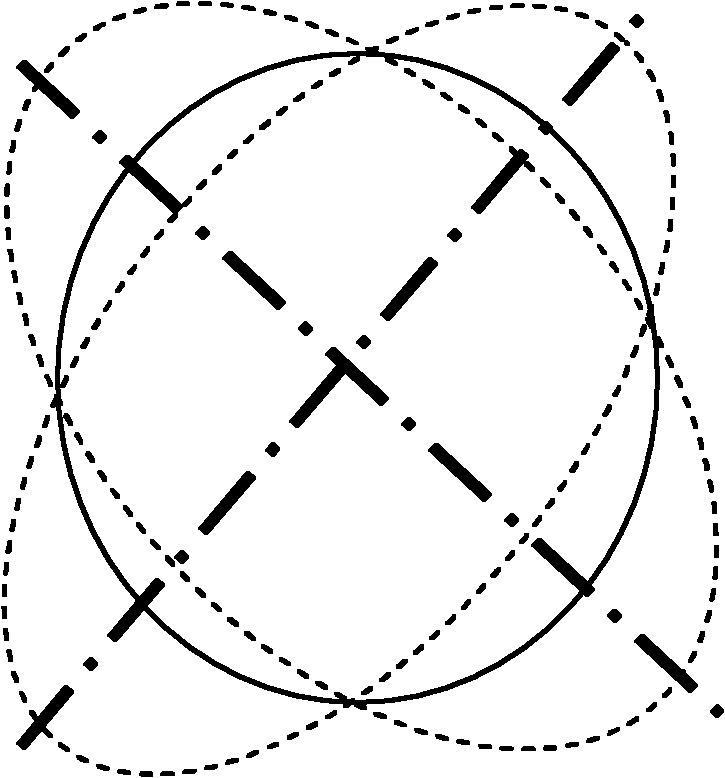

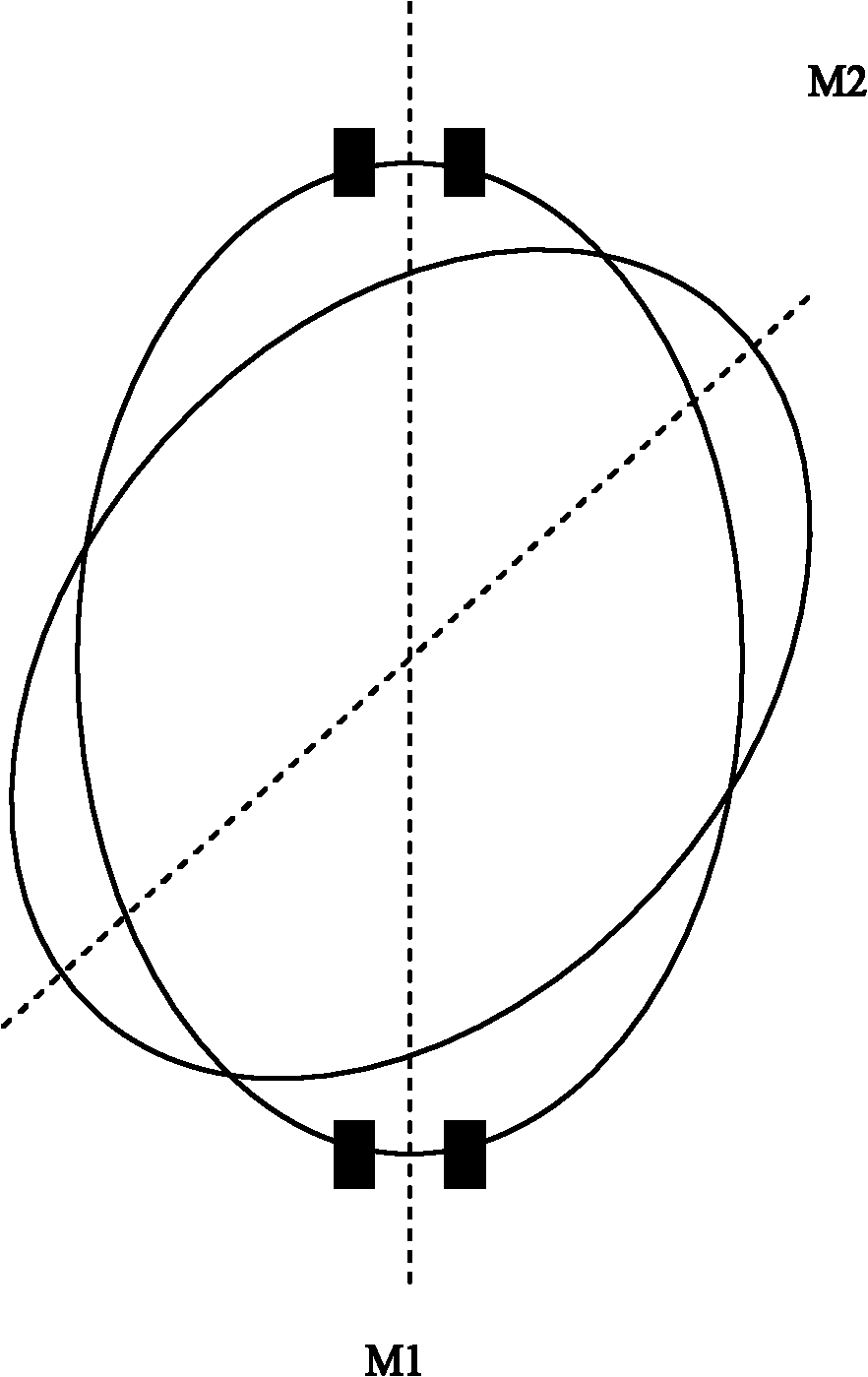

[0025] a kind of like Figure 7 , Figure 8 The cup-shaped resonator of the cup-shaped undulating gyroscope of the present invention shown, the cup-shaped resonator comprises a cylindrical side wall 1 and a circular chassis 2 ( The diameter of the chassis is 25mm), the side wall 1 includes a resonant ring 11 on the top and a vibration transmission part 12 on the bottom, a mounting base 21 is provided at the center of the chassis 2, and the resonant ring 11 is connected with the chassis 2 through the vibration transmission part 12. The top of the resonant ring 11 is evenly arranged with sixteen shaping grooves 3 (groove width 1 mm and groove depth 0.5 mm) along the circumferential direction, and eight shaping holes 4 (the diameter of the shaping holes are evenly arranged on the chassis 2 on the periphery of the mounting base 21 is 4.5mm). A piezoelectric electrode 5 is pasted between two adjacent modification holes 4 of the chassis 2, the vibration of the excited piezoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com