Methods of manufacturing anti-dazzle film and die for making anti-dazzle film

A manufacturing method and anti-glare film technology, which are applied in the field of anti-glare film manufacture and mold manufacturing for anti-glare film production, can solve the problems of brightness distribution being difficult to see clearly, dazzling, etc., to prevent the reduction of visibility, high contrast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

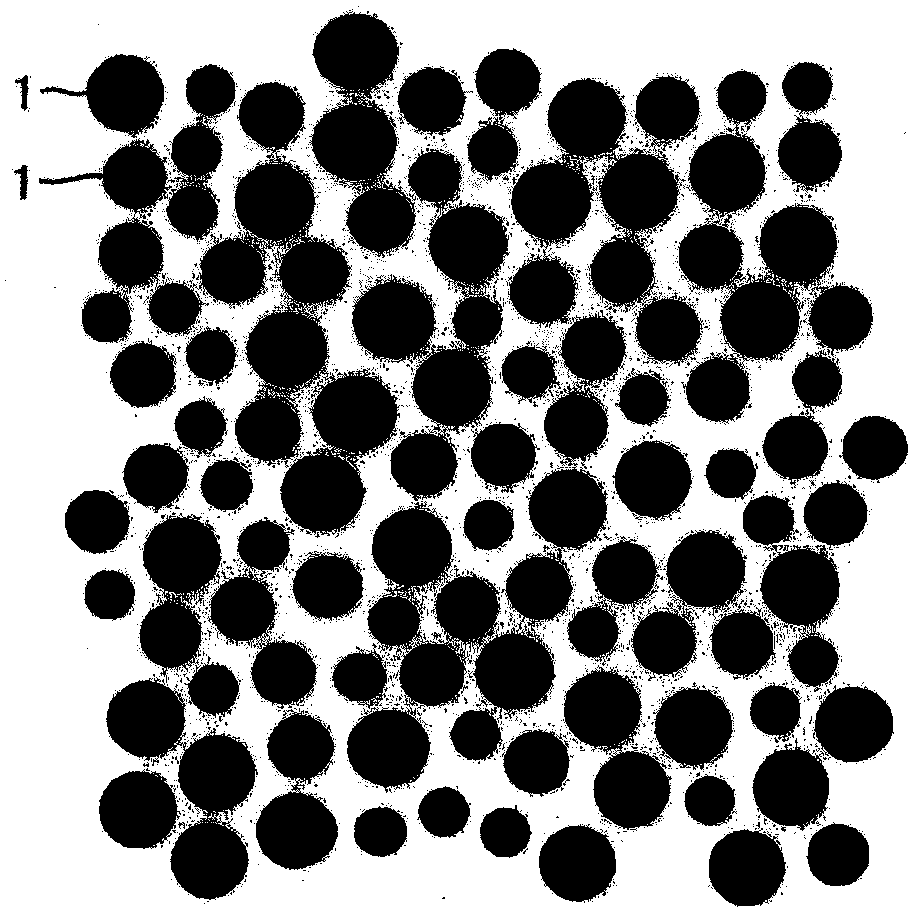

[0124] An aluminum coil (A5056 based on JIS) having a diameter of 200 mm on the surface of which copper ballard plating was applied was prepared. Copper Ballard plating consists of copper plating / thin silver plating / surface copper plating, and the overall thickness of the plating is set at about 200 μm. The copper-plated surface is mirror-polished, and a photosensitive resin is applied to the polished copper-plated surface, followed by drying to form a photosensitive resin film. Then, with laser light, the Figure 8 A pattern in which the shown patterns are repeatedly juxtaposed is exposed on the photosensitive resin film and developed. Exposure to laser light and development were performed using Laser Stream FX (manufactured by Think Laboratory Co., Ltd.). A positive photosensitive resin is used for the photosensitive resin film.

[0125] Then, the first etching treatment is performed with copper chloride solution. The etching amount at this time was set to 7 μm. The pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com