Polyurethane foam laminate, manufacturing method thereof, and gasket

A technology of polyurethane foam and manufacturing method, which is applied in the field of polyurethane foam layer, can solve problems such as reduced flame retardancy, sealing problems, and enlarged contact area, and achieves excellent flame retardancy, excellent adhesion, and small compression residual deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and 6~15

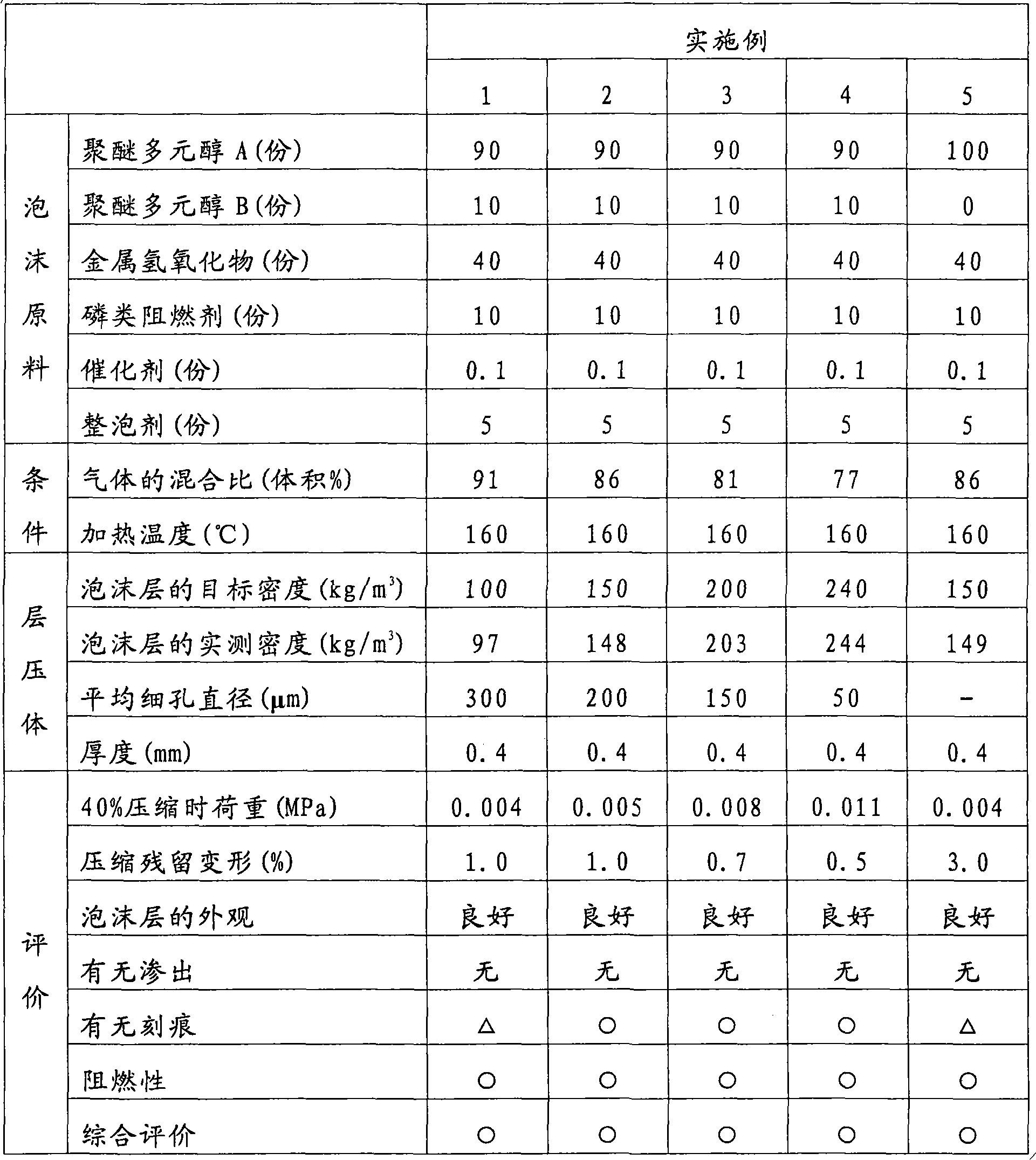

[0141] Examples 1-4 and 6-15, and Comparative Examples 1-7

[0142] 100 parts of polyether polyol (polyether polyol A and B are used in a mass ratio of 90 / 10), 0.1 part of catalyst, 5 parts of foam stabilizer, and metal hydroxides in the compounding amounts listed in Tables 1 to 4 Mix and stir the material powder and phosphorus flame retardant to prepare the first mixture.

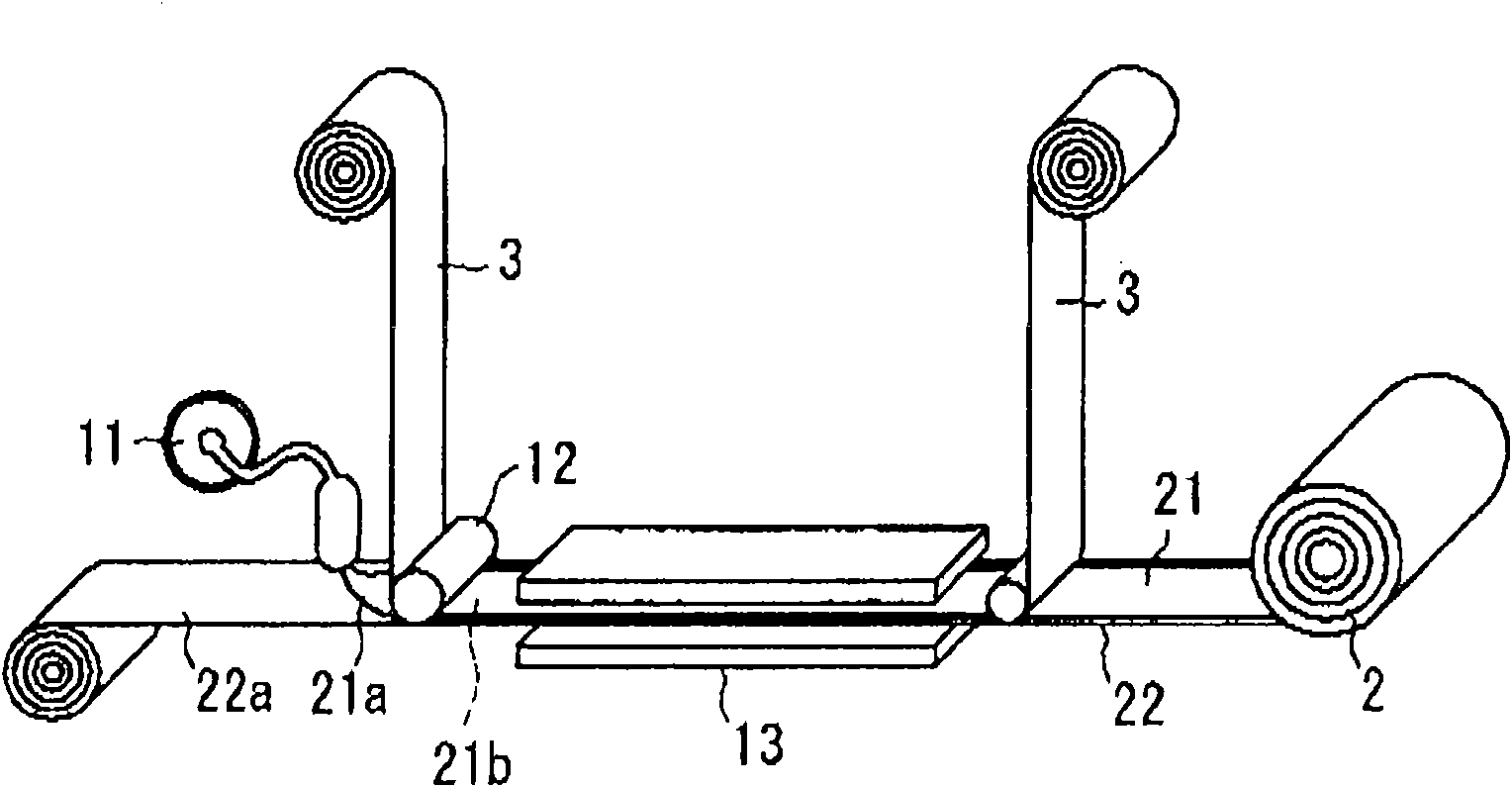

[0143] Then, put the first mixture and the polyisocyanate whose isocyanate index reaches 0.9-1.1 into the chamber of the Oaks mixer. Then, an amount of nitrogen gas in an amount to achieve a predetermined volume ratio described in Tables 1 to 4 was simultaneously injected so that the target density of the foam layer described in Tables 1 to 4 was achieved.

[0144] Secondly, the above-mentioned ingredients are stirred and mixed indoors to prepare a foamed gas-liquid mixture. And this gas-liquid mixture is supplied on the resin film conveyed at a speed of 5 m / min, and on the surface of the cast gas-liquid...

Embodiment 5

[0147] A polyurethane foam laminate was obtained in the same manner as above except that only 100 parts of polyether polyol A was used as the polyether polyol (Table 1).

[0148] Cut test pieces from the polyurethane foam laminate produced above, measure the density of the foam layer, the average pore diameter, the load at 40% compression, and the compression residual deformation, and evaluate the appearance of the foam layer, whether there is bleeding, whether there is a scratch, and flame retardant. The results are shown in Tables 1 to 4.

[0149] (1) The density of the foam layer

[0150] A square shape (50 mm×50 mm) was cut out from the obtained polyurethane foam laminate to prepare a test piece, and the vertical and horizontal dimensions of the test piece were accurately measured with a caliper. Then, the thickness of the resin film was subtracted from the thickness of the laminate shown in each table to obtain the thickness of the foam layer. Then, the volume of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com