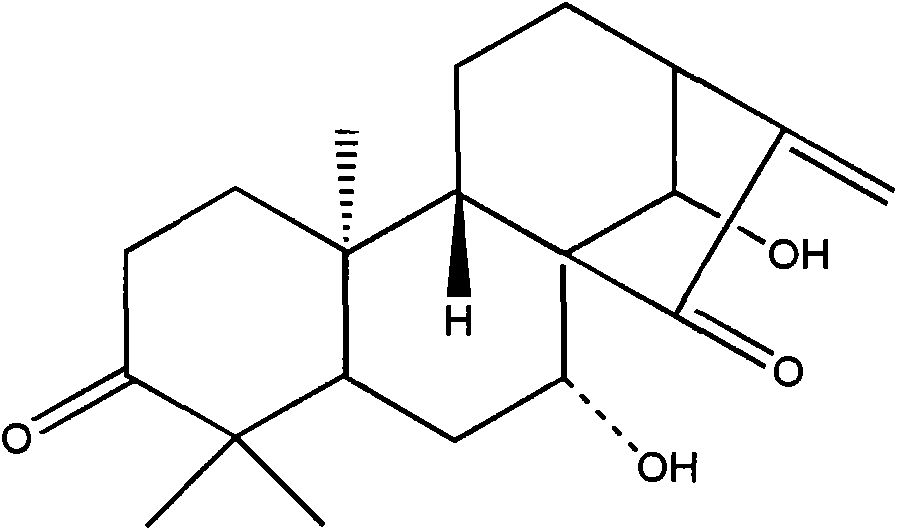

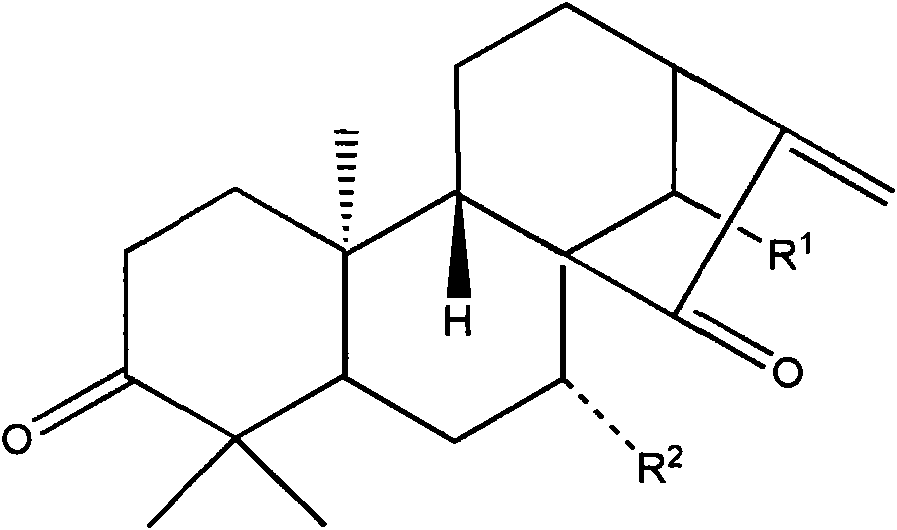

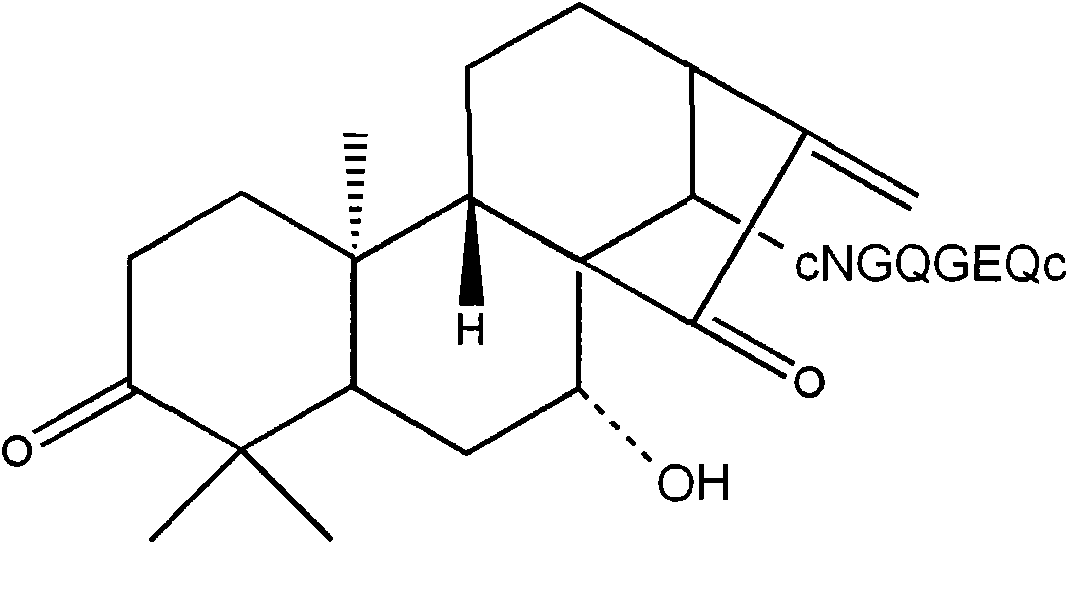

Glaucocalyxin A derivative, preparation method and application thereof

A technology of cyanine A and its derivatives, which is applied in the direction of drug combinations, pharmaceutical formulas, medical preparations containing active ingredients, etc., and can solve the problems of unreported pharmacological effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The preparation of embodiment 1 cyanine A (GLA) derivative:

[0067] The chemical reagents used in the following preparation process are analytically pure unless otherwise specified.

[0068] Using fragrant tea herbs (aerial parts) as a raw material, purifying cyanine A (GLA), and modifying its structure with a polypeptide cNGQGEQc, to prepare a method for preparing cyanine A (GLA) derivatives, specifically comprising the following steps:

[0069] Step 1: Crush

[0070] Take fragrant tea and vegetable medicinal materials (aerial parts) and pulverize to 20 mesh to 50 mesh.

[0071] Step 2: Extract

[0072] Step 2.1: Mix the pulverized product obtained in step 1 with 95% ethanol (A.R.) at a volume ratio of 1:6 to 1:10, heat, reflux at 80°C to 90°C for 1 to 2 hours, extract and filter, An extract and a residue are obtained.

[0073] Step 2.2: Mix the residue obtained in step 2.1 with 95% ethanol (A.R.) at a volume ratio of 1:6 to 1:10, heat, reflux at 80°C to 90°C for ...

Embodiment 2

[0107] The preparation of embodiment two cyanine A (GLA) derivatives:

[0108] Adopt the following technical parameters to improve the preparation method of embodiment one:

[0109] In the step 2.1, the pulverized product is mixed with 95% ethanol (A.R.) in a volume ratio of 1:6.5, heated, refluxed at 82° C. for 1.8 hours, and then extracted and filtered.

[0110] In the step 2.2, the residue is mixed with 95% ethanol (A.R.) at a volume ratio of 1:9.5, heated, refluxed at 88° C. for 1.2 hours, extracted and filtered, and this step is repeated once.

[0111] In the step 3.1, the extract is heated and concentrated under reduced pressure at a temperature of 57°C.

[0112] In the step 3.2, the primary concentrate and water were mixed in a volume ratio of 1:8.5, stirred at room temperature and then left to stand for 11 hours before the supernatant and solid were separated.

[0113] In the step 3.3, the solid was mixed with ethyl acetate (A.R.) at a volume ratio of 1:5.5, stirred ...

Embodiment 3

[0130] Preparation of embodiment three cyanine calyxin (GLA) derivatives:

[0131] Adopt the following technical parameters to improve the preparation method of embodiment one:

[0132] In the step 2.1, the pulverized product is mixed with 95% ethanol (A.R.) at a volume ratio of 1:7.5, heated, refluxed at 84° C. for 1.6 hours, and then extracted and filtered.

[0133] In the step 2.2, the residue is mixed with 95% ethanol (A.R.) at a volume ratio of 1:8.5, heated, refluxed at 86° C. for 1.4 hours, extracted and filtered, and this step is repeated once.

[0134] In the step 3.1, the extract is heated and concentrated under reduced pressure at a temperature of 59°C.

[0135] In the step 3.2, the primary concentrate and water were mixed at a volume ratio of 1:8.5, stirred at room temperature and then allowed to stand for 10 hours to separate the supernatant and solid.

[0136] In the step 3.3, the solid was mixed with ethyl acetate (A.R.) at a volume ratio of 1:5.5, stirred and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com