Adhesive, adhesive sheet using the same and method for producing adhesive sheet

A technology of adhesives and adhesive sheets, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc. Adhesion retention, the inability to optimize the curved surface of the base material, etc., to achieve the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083] Hereinafter, the present invention will be described more specifically by way of examples and comparative examples.

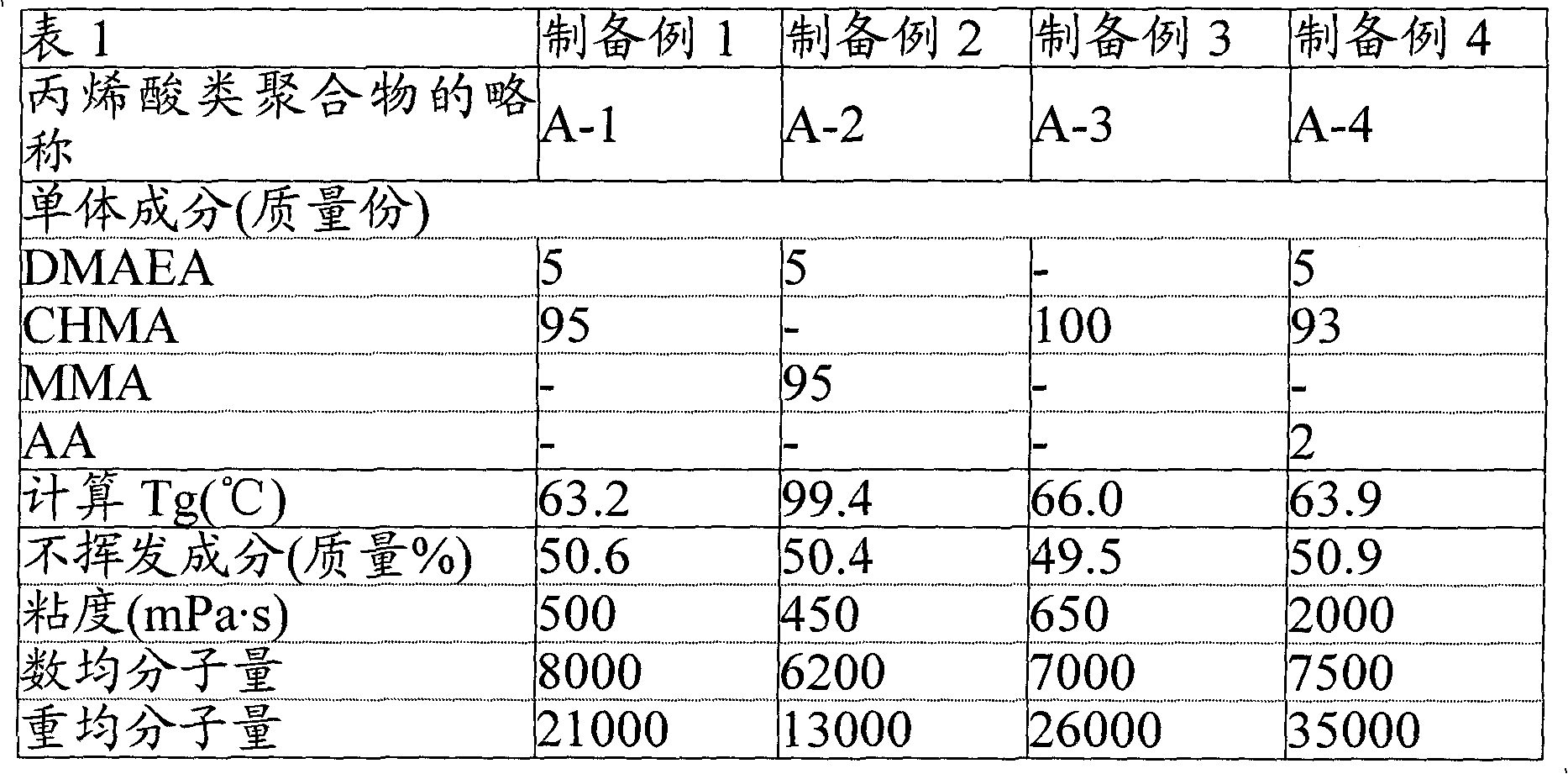

[0084] [Preparation of Acrylic Polymer]

preparation example 1

[0086] 35 parts by mass of toluene were charged into a reaction container equipped with a stirrer, a thermometer, a reflux cooling pipe, and a dropping funnel, and heated to a temperature of 90°C.

[0087] Next, premix 1 containing 95 parts by mass of cyclohexyl methacrylate and 5 parts by mass of N,N-dimethylaminoethyl acrylate, and 2 parts by mass of azobisisobutyronitrile as a polymerization initiator and Premix 2 with 50 parts by mass of toluene was added dropwise into the reaction container. The dropwise addition of the premix 1 was carried out for 6 hours, and the dropwise addition of the premix 2 was carried out for 6.5 hours.

[0088] After completion|finish of said dripping, the reaction liquid obtained by further heating at the same temperature for 2 hours was mixed with toluene, and the nonvolatile matter was 50.6 mass % of acrylic polymer (A-1) solutions.

preparation example 2

[0090] 35 parts by mass of toluene were charged into a reaction container equipped with a stirrer, a thermometer, a reflux cooling pipe, and a dropping funnel, and heated to a temperature of 90°C.

[0091] Next, premix 3 containing 95 parts by mass of methyl methacrylate and 5 parts by mass of N,N-dimethylaminoethyl acrylate, and 2 parts by mass of azobisisobutyronitrile as a polymerization initiator and toluene 50 parts by mass of premix 4 were added dropwise into the reaction container. The dropwise addition of the premix 3 was carried out for 6 hours, and the dropwise addition of the premix 4 was carried out for 6.5 hours.

[0092] After completion|finish of said dripping, the reaction liquid obtained by further heating at the same temperature for 2 hours was mixed with toluene, and the nonvolatile matter was 50.4 mass % of acrylic polymer (A-2) solutions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com