Metal salts of higher fatty acids and electronic photographic equipment

A high-grade fatty acid and metal salt technology, which is applied in the direction of electrography, anionic surface active compounds, and electric recording technology using charge patterns, etc., can solve the problem of increased grinding amount, shortened molded body life, and unstable abrasiveness, etc. problem, to achieve a good supply state, the effect of small hardness deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

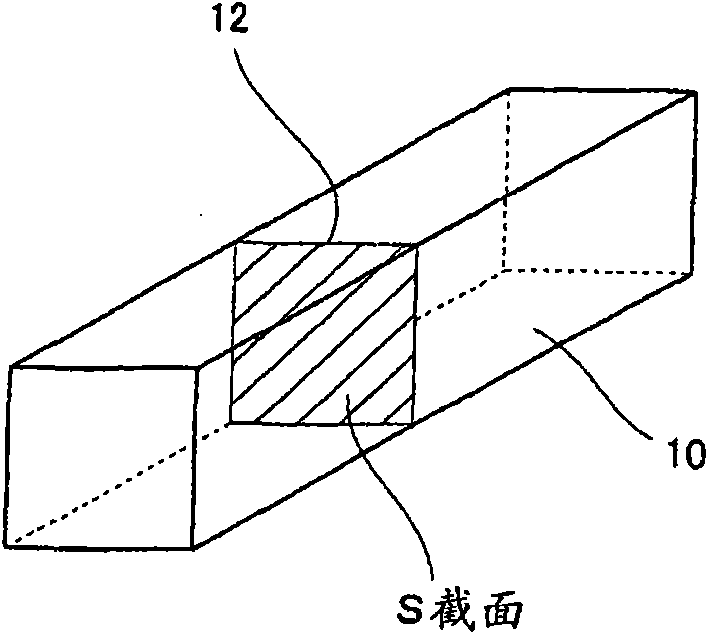

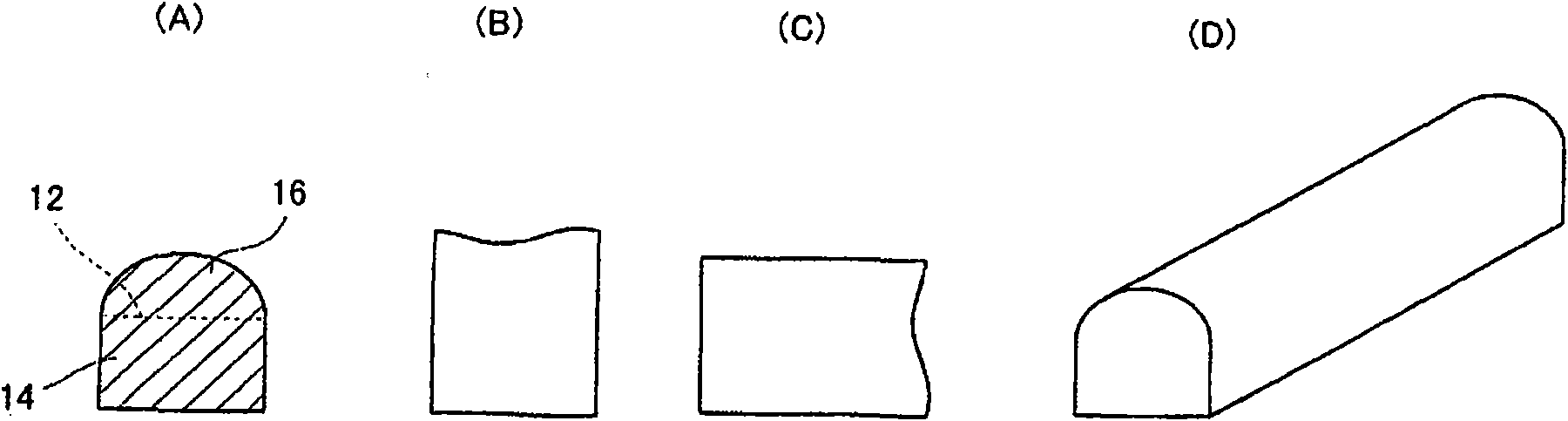

[0063] Mold ( Figure 11 ) is to have such as figure 2 The shape of the groove of the S-section block molded body shown in (A) is 5 mm in length x 5 mm in width and 310 mm in length. Insert 10 molds and 3 heaters with 16 fastening bolt holes spaced on the left and right. A plate and a flat plate are combined and fastened so that the groove surface is in contact with the flat surface of other molds, and installed on a mold base equipped with a heater insertion port and a cooling mechanism as a combination of molds that can mold a total of 320 blocks ( Figure 12 , Figure 13 ). In addition, 3 sheath heaters are installed on the top, middle and bottom of the mold, and 2 sheath heaters are installed on the cover plate for heat insulation and the mold base, for a total of 13. Sheath heater. In addition, in the figure, 41 is the upper heater insertion port, 42 is the middle heater insertion port, 43 is the lower heater insertion port, 44 is the temperature drop sensor inserti...

Embodiment 2

[0065] In addition to the change becomes to have as image 3 A higher fatty acid metal salt block shaped body was produced in the same manner as in Example 1 except for the die having grooves of the S-section block shaped body shown in (A). The results are shown in Table 1.

Embodiment 3

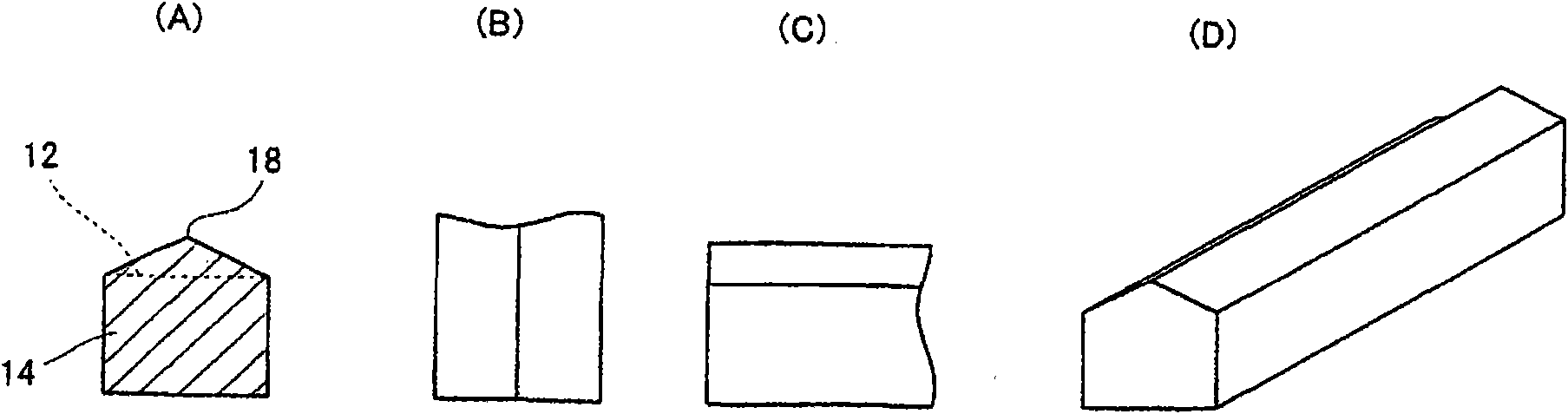

[0067] In addition to the change becomes to have as Figure 4 A higher fatty acid metal salt block shaped body was produced in the same manner as in Example 1 except for the die having grooves of the S-section block shaped body shown in (A). The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com