A Multi-Aperture Fixture for End Grinding Single Fibers or Chips

A multi-aperture and fixture technology, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve problems such as the contradiction between processing accuracy and quantity, and the production capacity bottleneck of optical splitters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

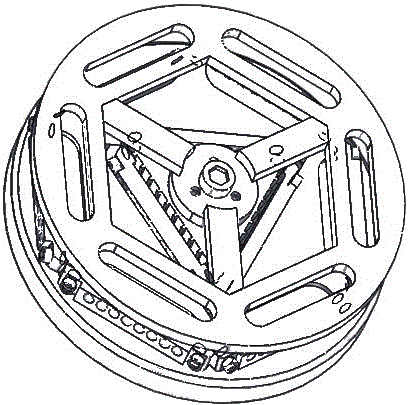

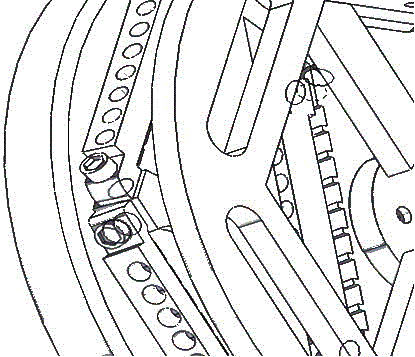

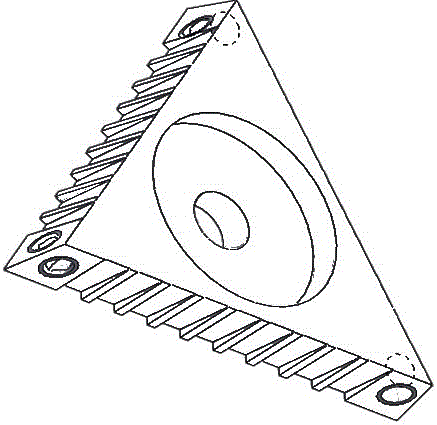

[0022] The technical scheme adopted in the present invention is as Figure 1A , 1B As shown, according to the present invention, the multi-aperture single fiber (Pigtail) or chip (chip) grinding jig includes a base, and the base is provided with two layers of positioning platens inside and outside. equilateral triangles (such as figure 2 shown), a clamping mechanism is set in the groove. The outer positioning platform is composed of a regular hexagon with equidistant grooves on the edge (such as image 3 shown), a clamping mechanism is set in the groove. The two-layer positioning platform is connected by a round top cover with a hole, such as Figure 4 shown. Such as Figure 5A and 5B As shown, the base includes an iron ring of a certain thickness (such as Figure 6 As shown) and the base body; two layers of circular bosses with different thicknesses are dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com