Novel pulverizing mill for preparing aluminate cement

A kind of technology of aluminate cement and grinding machine, which is applied in the direction of separating solids from solids with airflow, solid separation, grain processing, etc. It can solve problems such as unfavorable high-efficiency production, increased production costs, and blade wear. Achieve the effects of increasing practicability, increasing service life and increasing grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

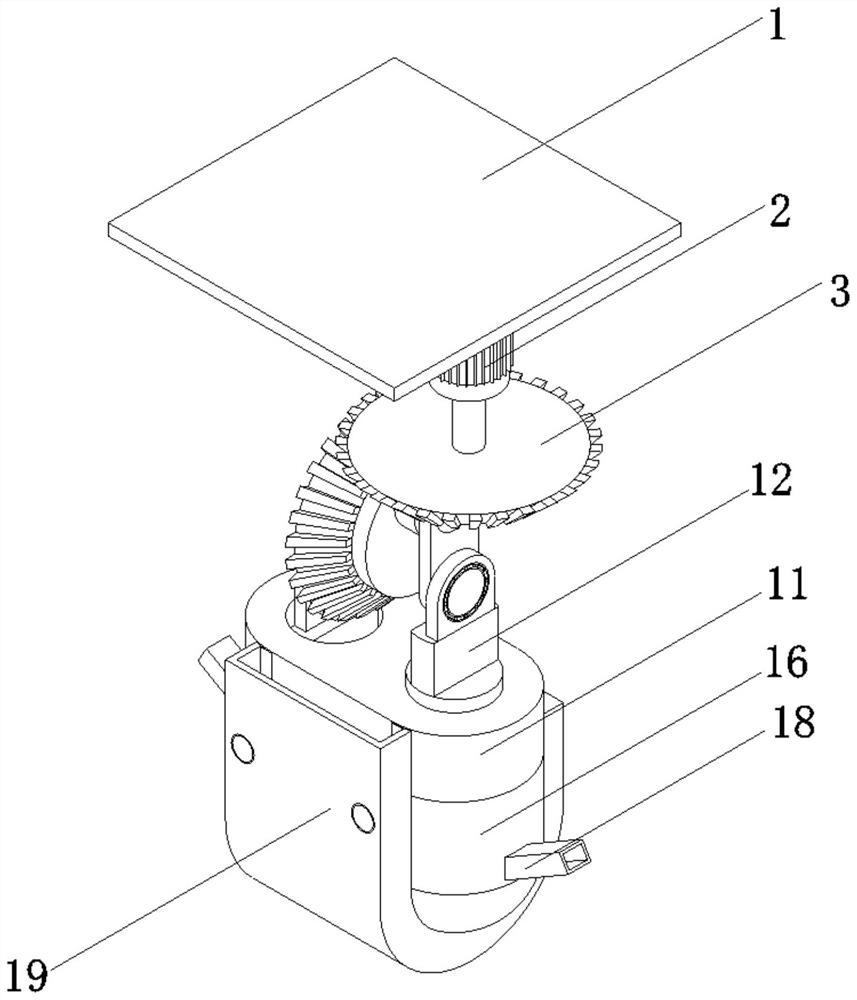

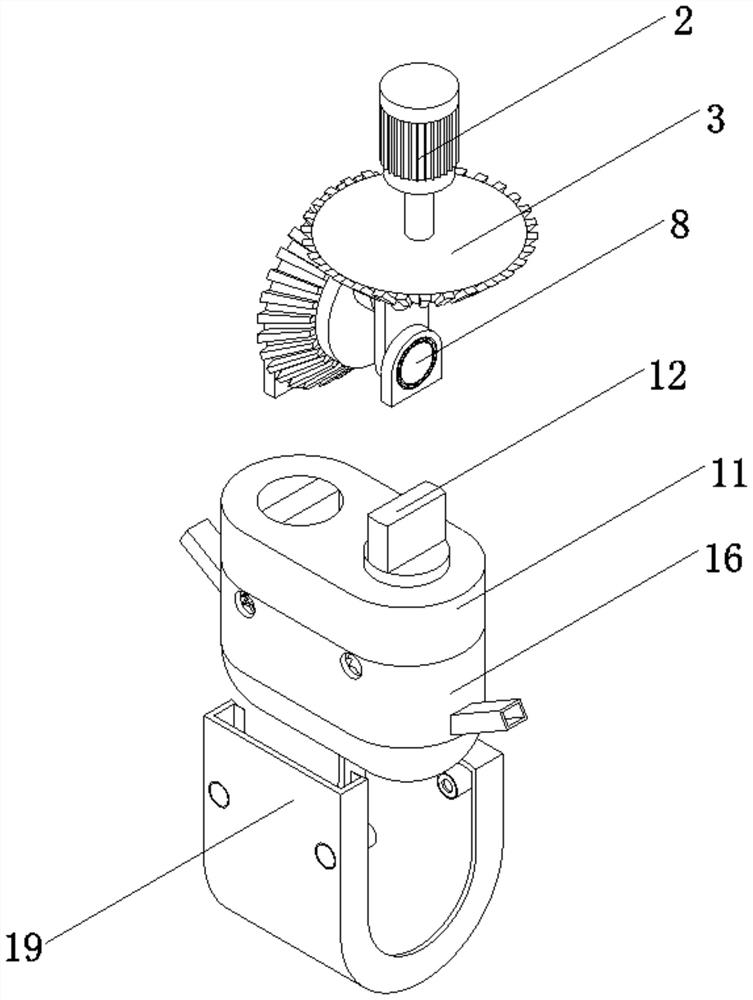

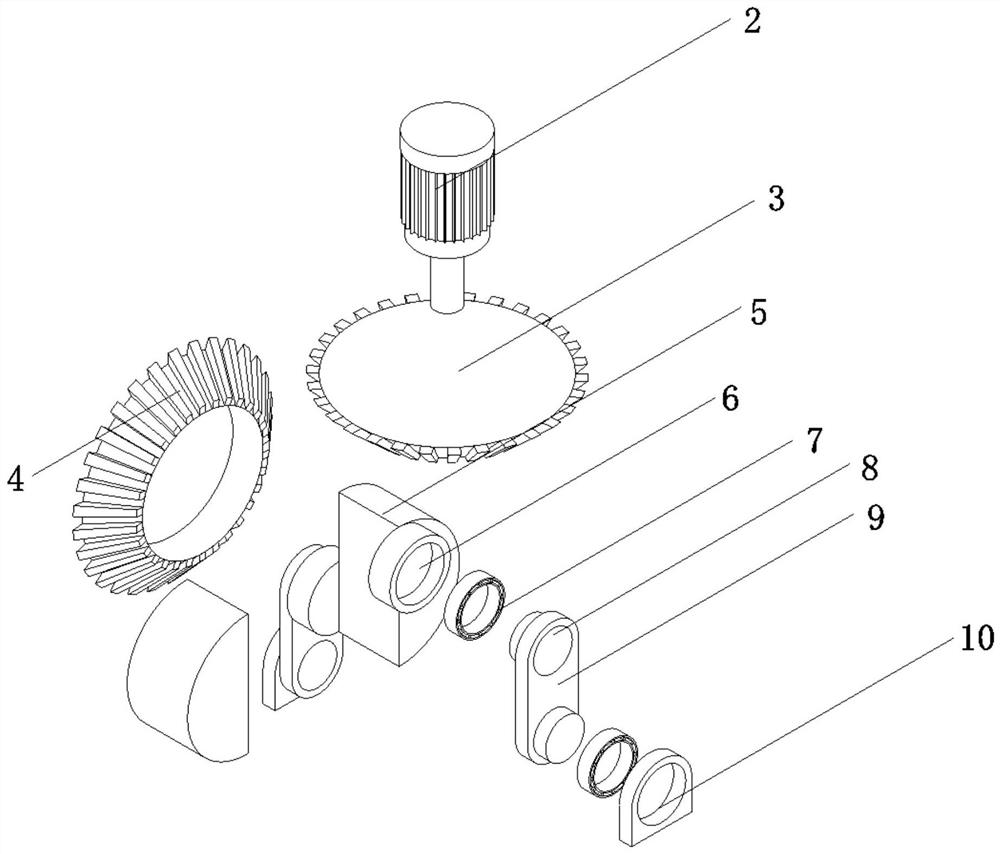

[0026] see Figure 1 to Figure 2 , the present invention provides a technical solution: a novel grinding machine for aluminate cement preparation, including a top fixing plate 1 and a limit sleeve 11, a driving motor 2 is fixedly installed under the top fixing plate 1, and the driving motor 2 outputs The bottom of the shaft is fixedly connected with the active bevel gear 3, the left side of the bottom of the active bevel gear 3 is meshed with the driven bevel gear sleeve 4 through the tooth groove, the inner cavity of the driven bevel gear sleeve 4 is fixedly installed with the rotating column 5, and the driving motor 2 And the setting of driving bevel gear 3, driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com