A device for crushing medicinal materials

A crushing device and medicinal material technology, applied in cocoa, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inability to carry out large-scale milling, inability to control the amount of feed, and inability to achieve sufficient crushing, etc., to achieve The structure is simple, the crushing efficiency is improved, and the crushing effect is sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

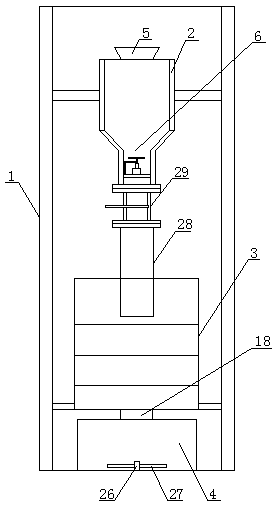

[0020] Such as Figure 1-7 As shown, a medicinal material pulverizing device of the present invention includes a frame 1, and the frame 1 is sequentially provided with a tablet feeding box 2, a grinding box 3 and a storage tank 4 from top to bottom, and the feeding box 2 is connected to the grinding box 3 , The grinding box 3 is connected with the storage tank 4 .

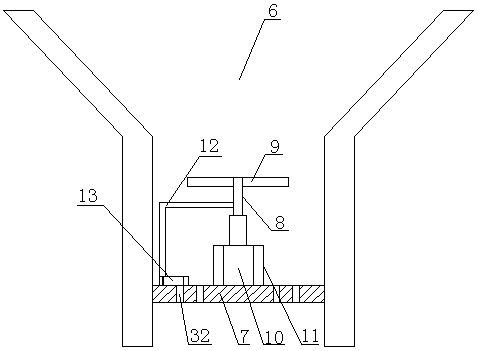

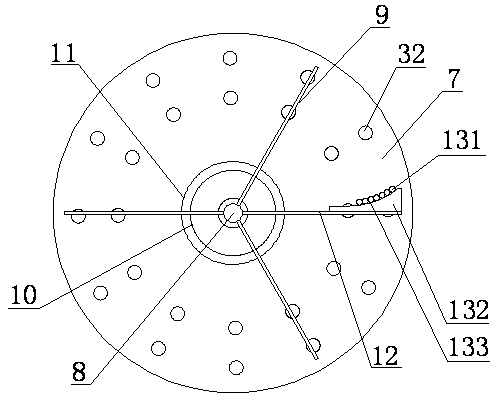

[0021] The top of the feed box 2 is provided with a material inlet 5, and the bottom of the feed box 2 is provided with a discharge port I6. The discharge port I6 is funnel-shaped, and a crushing device is installed in the discharge port I6 through a circular fixing plate 7. device, the crushing device includes a crushing shaft 8, crushing blades 9 and a crushing motor 10, the outside of the crushing motor 10 is provided with a dust cover 11, and the crushing motor 10 is fixedly insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com