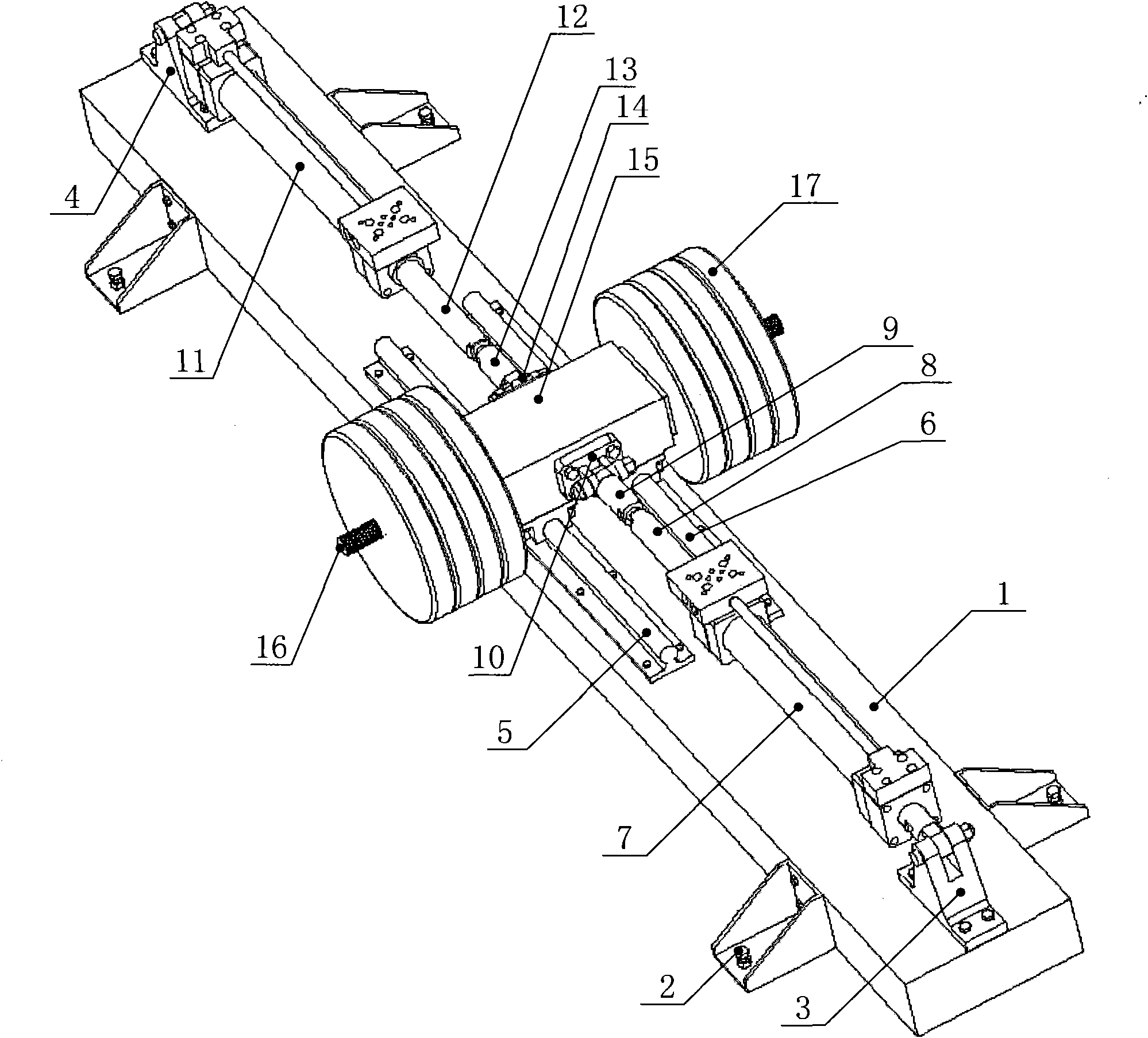

Experiment table for testing hydraulic servo system

A technology of hydraulic servo system and test bench, which is applied in the field of test benches, can solve the problems of high risk, high experiment cost, and high risk, and achieve the effect of reducing experiment cost and risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

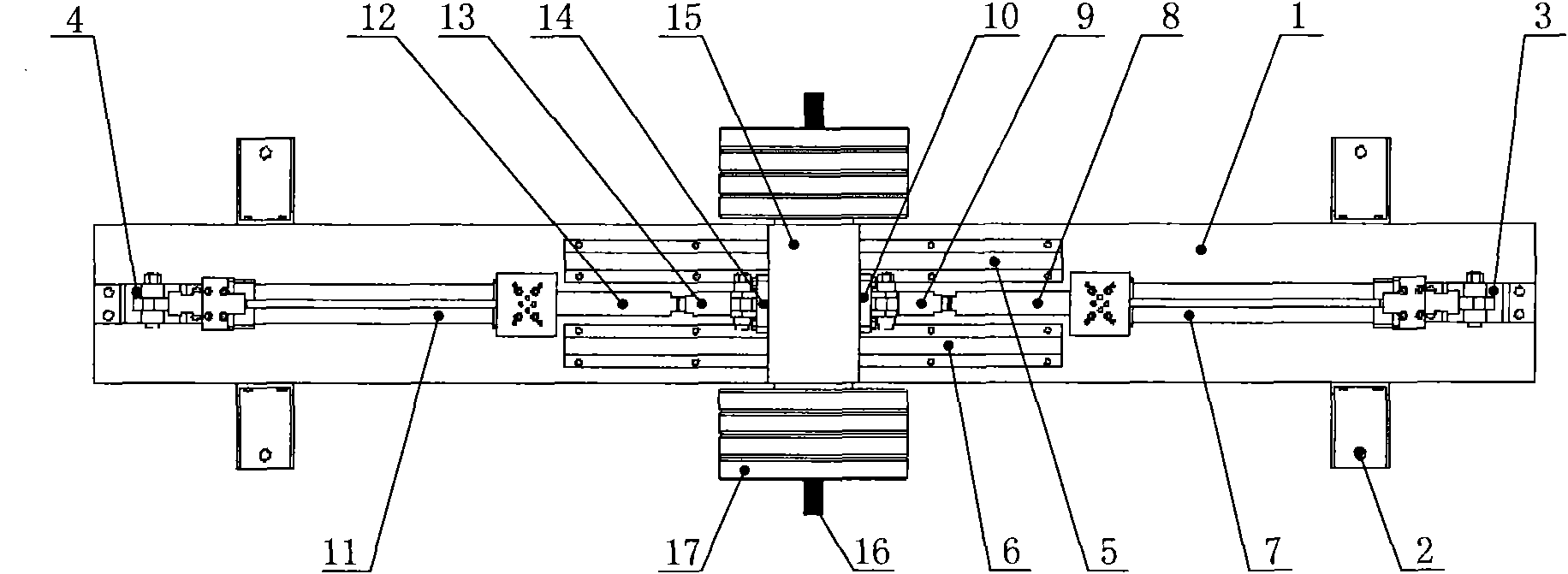

[0030] The first embodiment is to conduct an experimental study on the force control of the hydraulic cylinder drive unit.

[0031] In this embodiment, the second hydraulic cylinder drive unit can be removed. The first hydraulic cylinder drive unit drives the sliding table 15 to move back and forth along the guide rails 5 and 6, and the control target is the piston rod 8 of the first hydraulic cylinder drive unit and the first hydraulic The force value of the pressure sensor is pulled between the piston rod lugs 9 of the cylinder drive unit. The first hydraulic cylinder drive unit can generate the desired continuous output force.

Embodiment 2

[0032] In the second embodiment, the position servo control of the hydraulic cylinder drive unit under the condition of continuous external load is carried out.

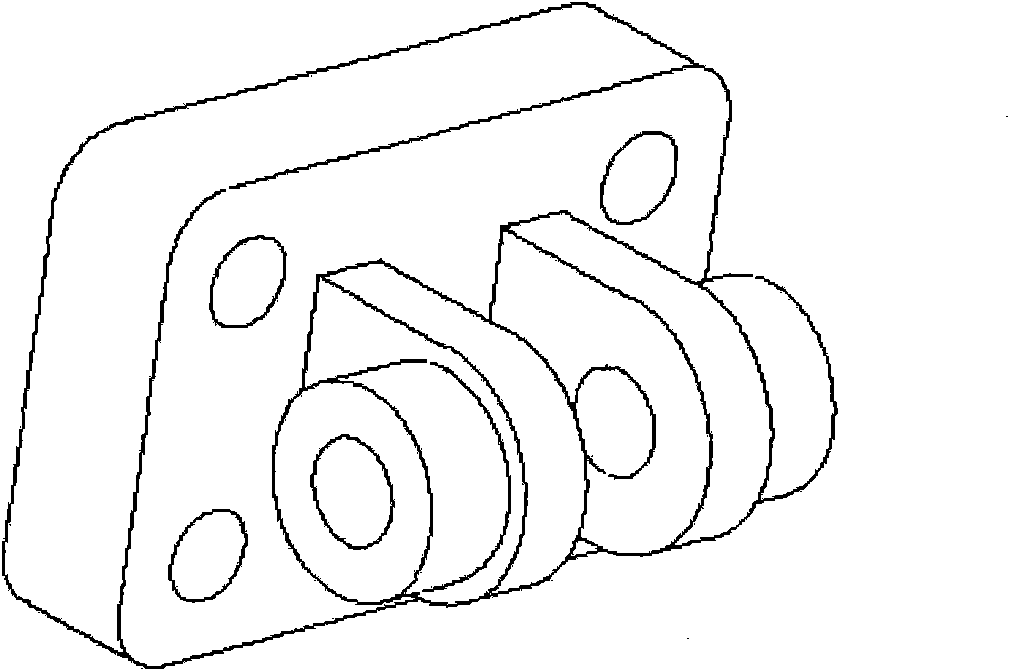

[0033] In this embodiment, the controlled system is a position servo control system composed of the first hydraulic cylinder drive unit, the sliding table 15 and its load 17, and so on. Install the first hydraulic cylinder drive unit and the second hydraulic cylinder drive unit at the same time, the first hydraulic cylinder drive unit generates continuous external interference force, and the first hydraulic cylinder drive unit adopts position control. Under the continuous external interference force, when different control strategies or algorithms are adopted, the present invention can realize the research on the position servo control performance of the controlled system. According to another example of the present invention, it is possible to adopt Figure 4 The structural diagram of the lengthened connecting block sh...

Embodiment 3

[0035] Implementation example three, carry out the position servo control experiment of the hydraulic drive unit under the condition of discontinuous external force load.

[0036] In this embodiment, the controlled system is a position servo control system composed of the first hydraulic cylinder drive unit, the sliding table 15 and its load 17, etc., and the first hydraulic cylinder drive unit and the second hydraulic cylinder drive unit are installed at the same time. The two hydraulic cylinder drive unit adopts force control. The first lug 13 of the first hydraulic cylinder drive unit drives the pin (or bolt) installed on it to slide in the long groove of the extension connecting block 10. At this time, the first hydraulic cylinder The external interference force applied by the position servo control system constituted by the drive unit, the sliding table 15 and its load 17, etc. is zero. When the pin (bolt) reaches the two ends of the long groove of the elongated connecting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com