High anti-damage energy transfer optical fiber and manufacturing method

An energy-transfer optical fiber and high-resistance technology, which is applied in the direction of cladding optical fiber, manufacturing tools, optical waveguides, etc., can solve the problems of low numerical aperture, high manufacturing cost, and low damage threshold of energy-transmitting optical fibers, and achieve simplification of the manufacturing process , low transmission loss and high damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

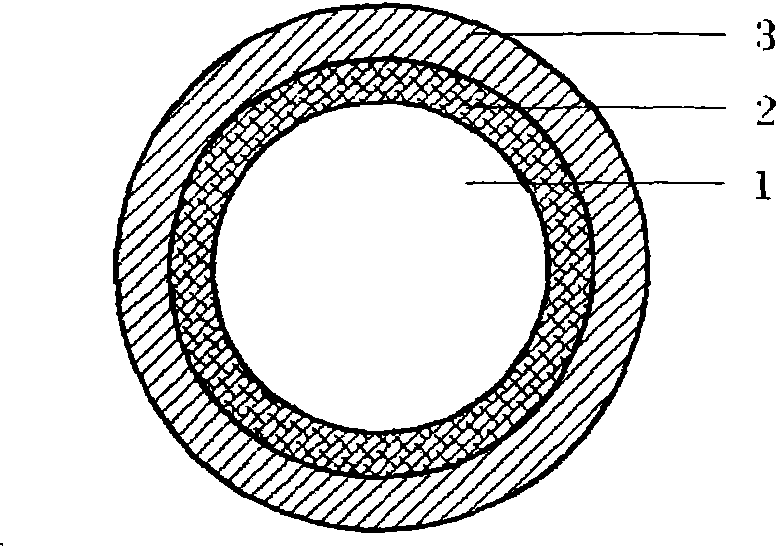

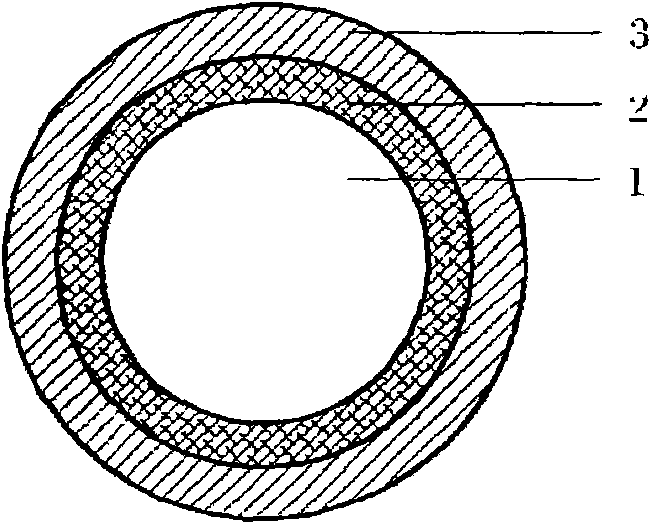

Embodiment 1

[0024] Embodiment 1: The periphery of the optical fiber pure silica core 1 is covered with a heat-cured low-refractive-index silicone rubber material cladding 2 , and a UV-cured acrylic resin protective layer 3 is covered on the cladding 2 . The diameter of the core 1 is 50 μm, and the refractive index range of the core 1 is 1.456; the diameter of the cladding 2 is 60 μm, and the refractive index of the cladding is 1.398; the diameter of the outer protective layer 3 is 125 μm; the outer The refractive index of the protective layer 3 is 1.410.

Embodiment 2

[0025] Embodiment 2: The periphery of the pure silica fiber core 1 of an optical fiber is covered with a low-refractive-index optical fiber coating resin material cladding 2 , and a heat-cured low-refractive-index silicone rubber protective layer 3 is covered on the cladding 2 . The diameter of the core 1 is 400 μm, and the refractive index range of the core 1 is 1.457; the diameter of the cladding 2 is 500 μm, and the refractive index of the cladding is 1.365; the diameter of the outer protective layer 3 is 580 μm; the outer The refractive index of the protective layer 3 is 1.380.

Embodiment 3

[0026] Embodiment 3: The periphery of the optical fiber pure silica core 1 is covered with a thermally cured low-refractive index polyimide material cladding 2 , and the thermally cured low-refractive polyimide protective layer 3 is covered on the cladding 2 . The diameter of the core 1 is 1000 μm, and the refractive index range of the core 1 is 1.458; the diameter of the cladding 2 is 1200 μm, and the refractive index of the cladding is 1.410; the diameter of the outer protective layer 3 is 1400 μm; the outer The refractive index of the protective layer 3 is 1.410.

[0027] The manufacturing process is as follows: the optical fiber pure silica core preform is directly made of a synthetic low-hydroxyl pure silica rod or tube; the low-hydroxyl pure silica rod or tube is melted at a high temperature of 2150°C in a graphite resistance furnace or a graphite induction furnace, and pulled under a certain tension The fiber core is made by stretching and drawing; the larger the core d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com