Novel technology for assembling transformers

An assembly process and transformer technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of not necessarily accurate positioning of the transformer body, high skill requirements for operators, and high labor intensity for operators. Achieve the effects of reducing skill requirements, improving the working environment, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

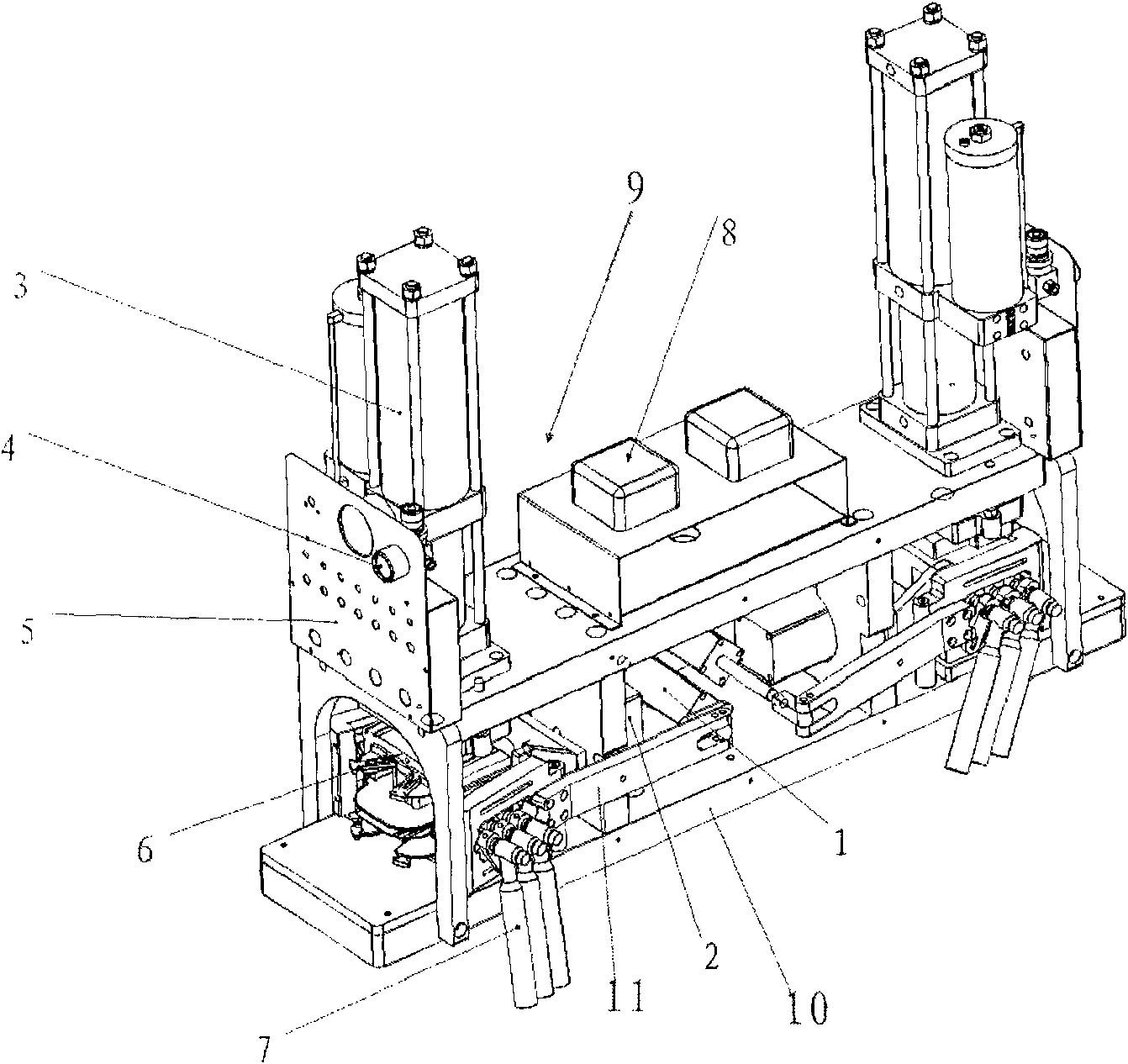

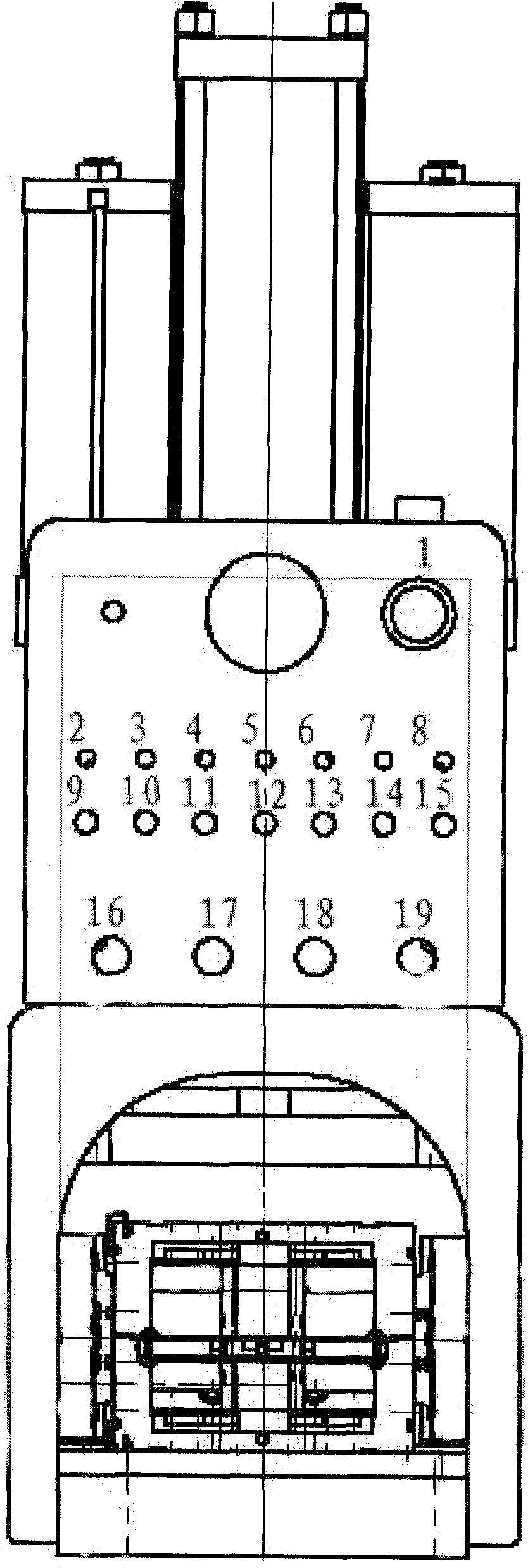

[0025] figure 1 It is a schematic diagram of a novel transformer assembly process of the present invention. Such as figure 1 Shown, the present invention is fixed on the workbench (10), and for reducing working space, the present invention installs 2 stations under a set of devices, and these 2 stations can work simultaneously, also can work independently. Combine below figure 1 , according to the working principle of one of the stations, for further explanation.

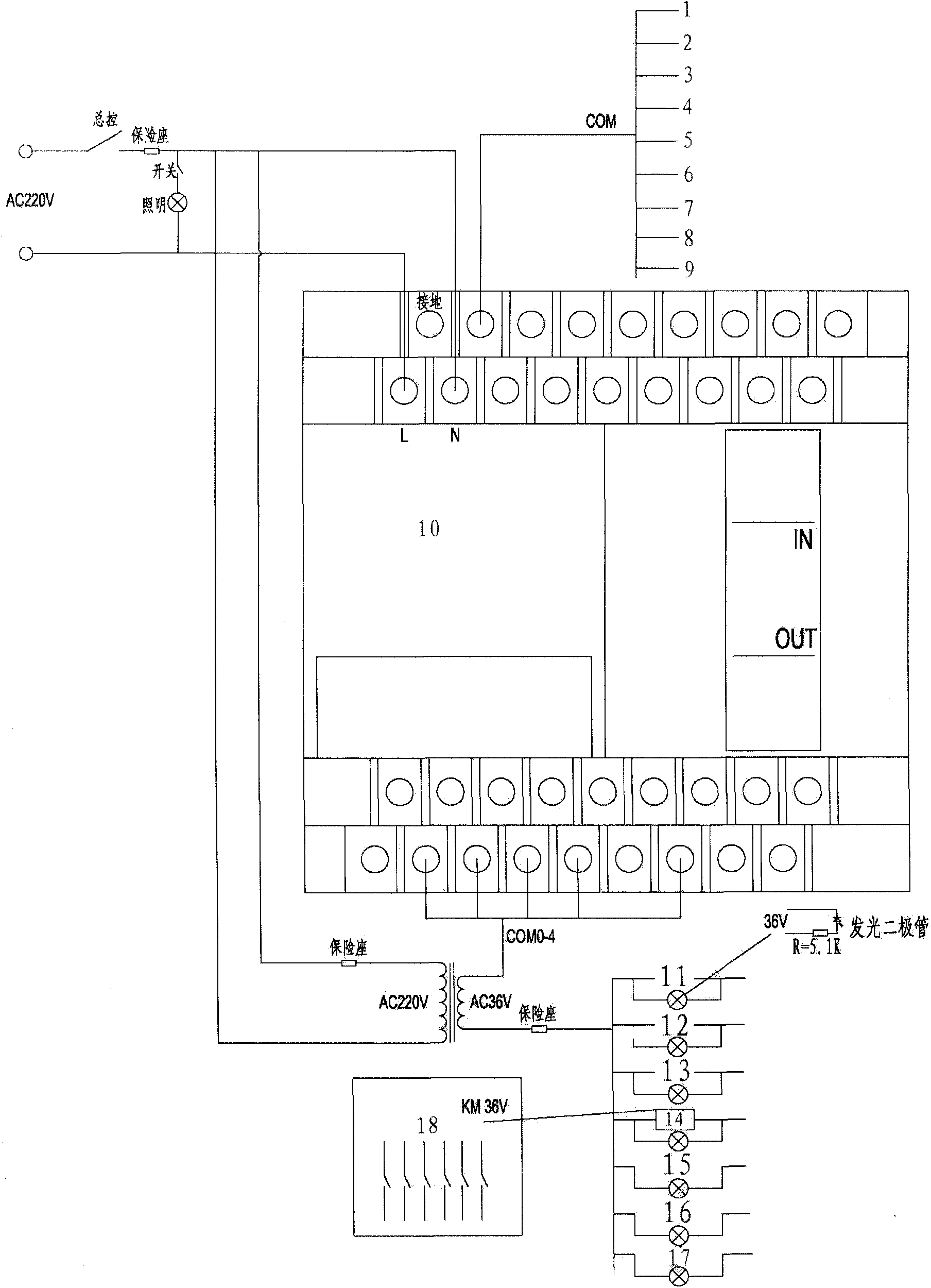

[0026] Such as figure 1 As shown, the clamping cylinder (1), the jacking cylinder (2), and the programmable logic controller PLC (8) are all installed in the electrical box (9), wherein the clamping cylinder (1) and the jacking cylinder (2) The iron plate shaft (11) is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com