High-precision radio frequency coaxial connector

A radio frequency coaxial and connector technology, which is applied in the direction of connection, conductive connection, and parts of the connection device, can solve the problems of unfavorable sample trial production, extremely strict mechanical processing technology requirements, and reduce the effective strength of the support. The effect of precision control and consistency, excellent electrical performance indicators, and stable mass production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

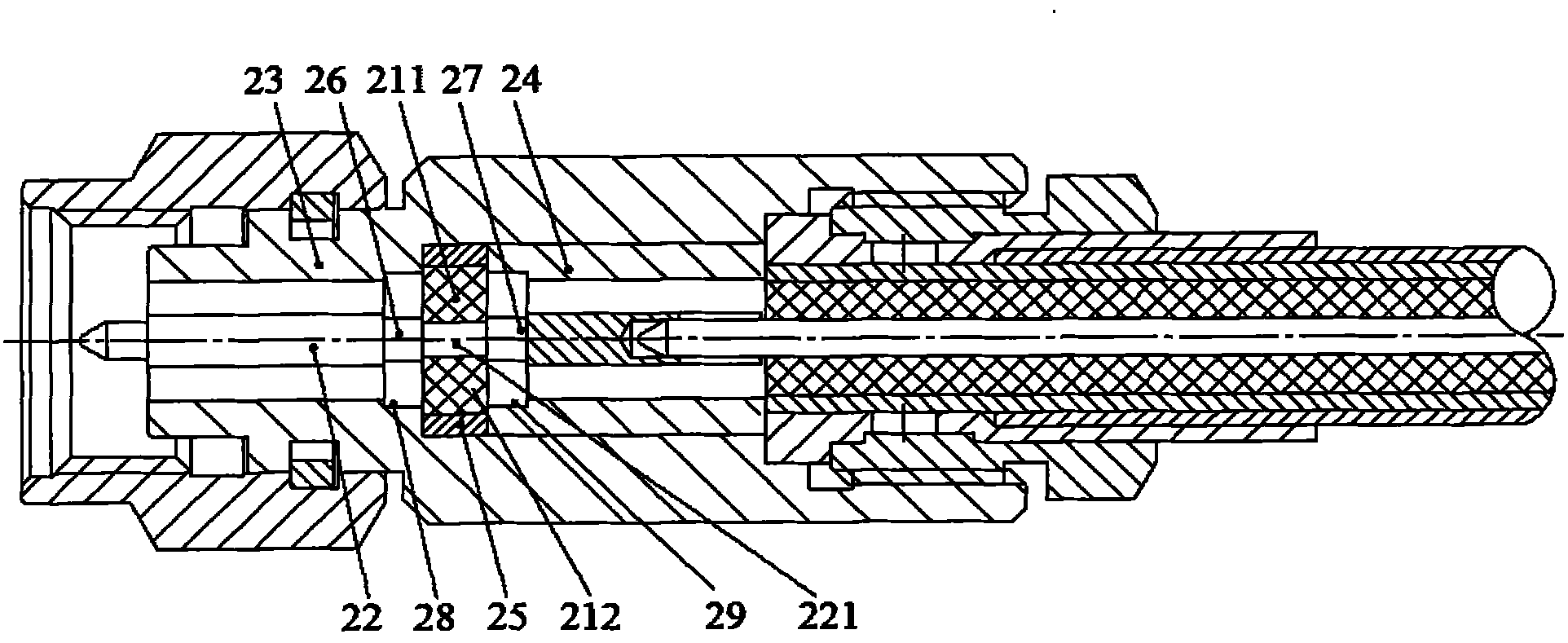

[0028] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

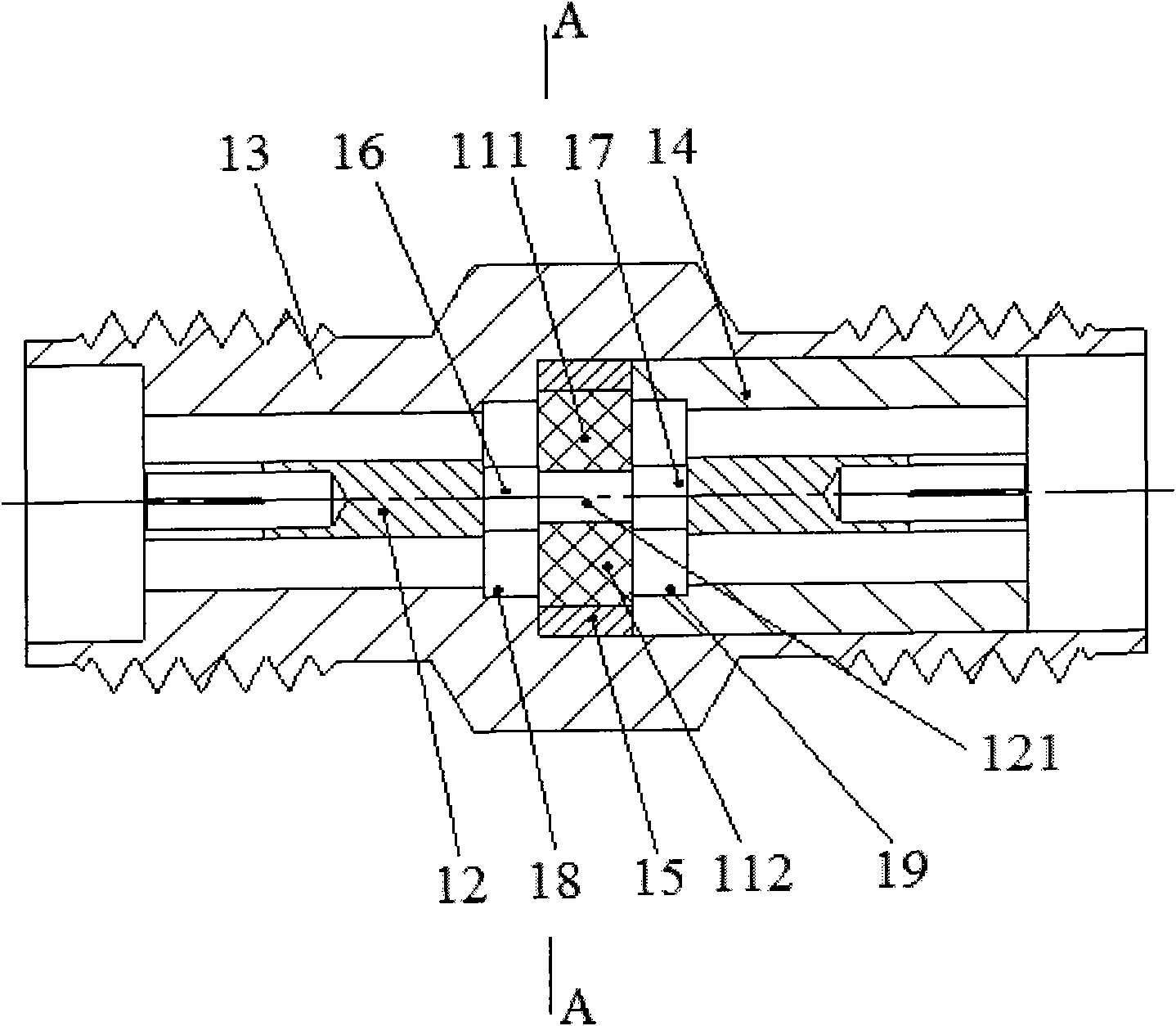

[0029] like Figure 1-Figure 2 As shown, a high-precision RF coaxial connector provided by the first embodiment of the present invention includes a support member, an outer conductor and an inner conductor 12;

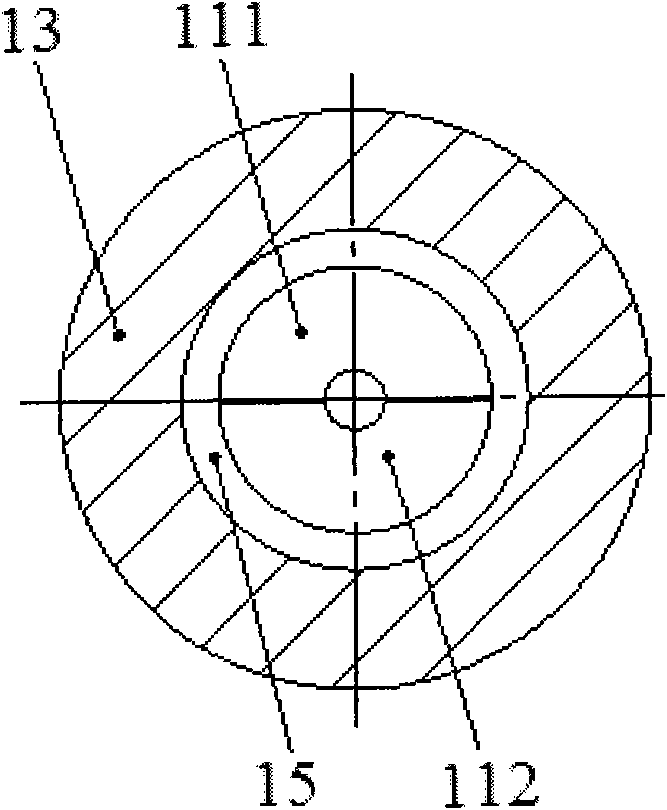

[0030] The supporter includes an upper supporter 111 and a lower supporter 112, the upper supporter 111 is engaged with the lower supporter 112 in the opposite direction, and is bound by a supporter ring 15;

[0031] The outer conductor is provided with a hollow inner cavity, which is composed of a left outer conductor 13 and a right outer conductor 14, and the right end of the left outer conductor 13 is joined with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com