Liquefied-gas carrying vessel

A technology for transport ships and liquefied gas, applied in the field of LNG ships, can solve the problems of increased hull weight, improved navigation performance, hull resistance, etc., and achieves the effects of reducing width, improving navigation performance, and reducing hull resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

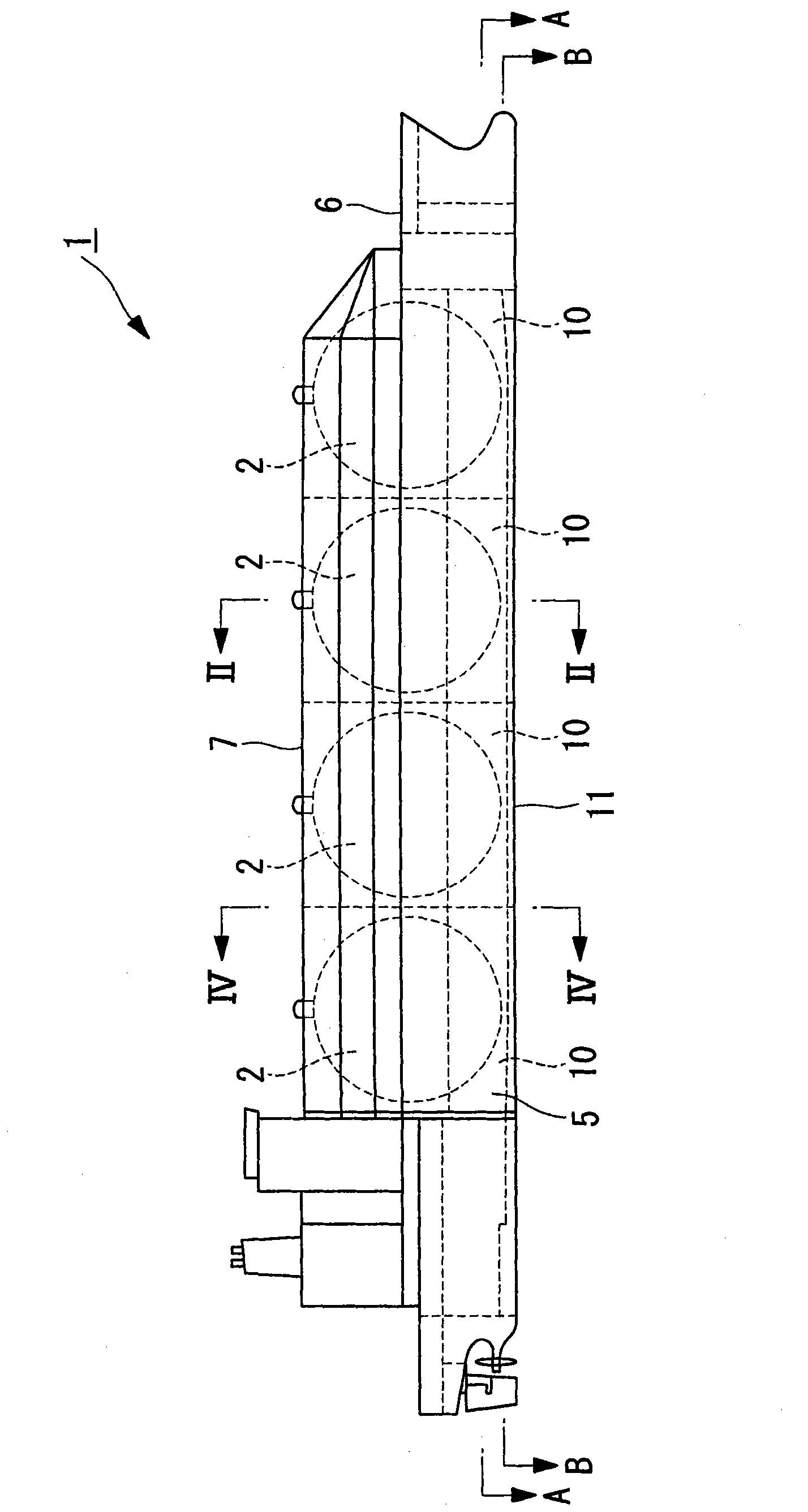

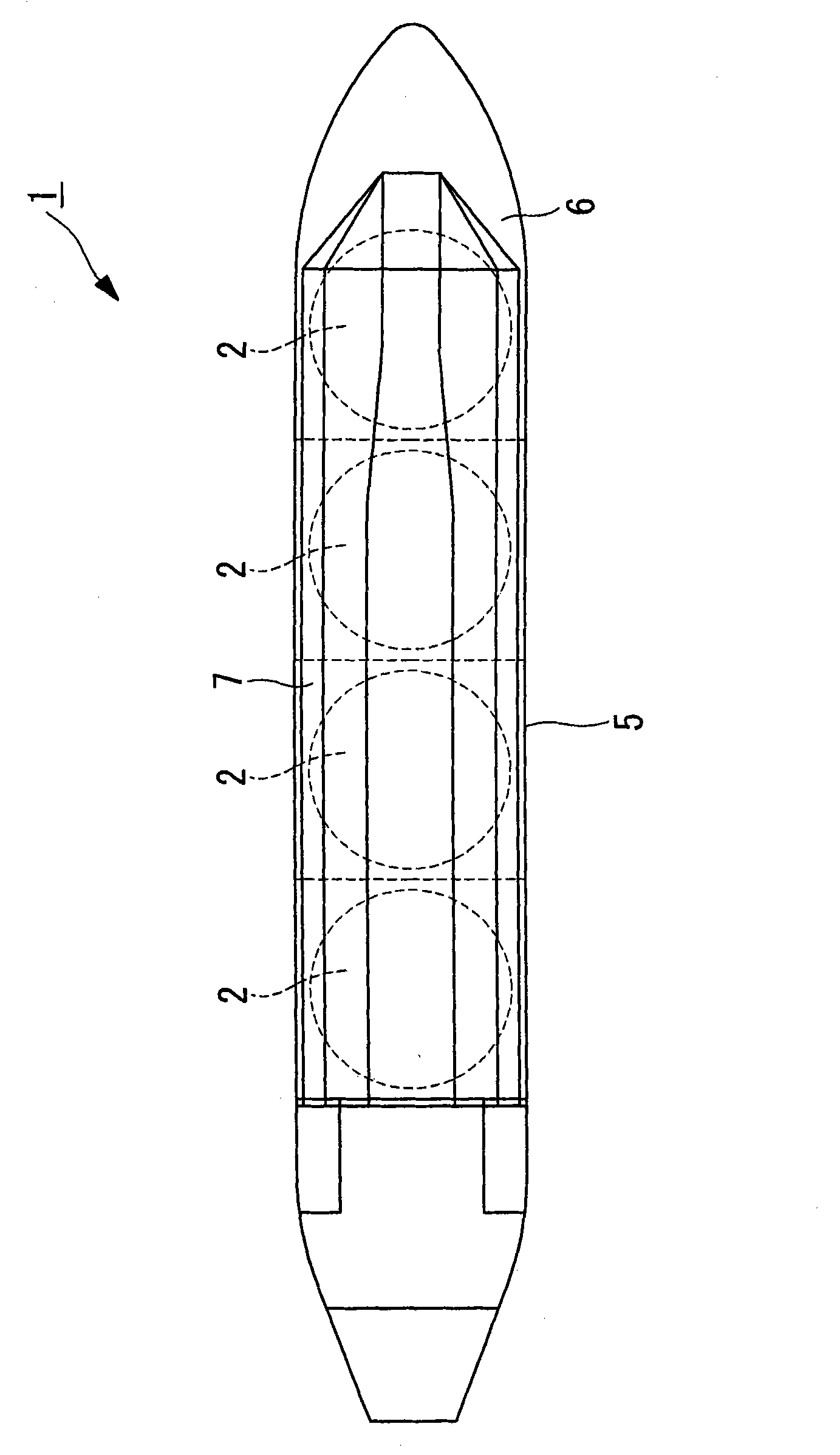

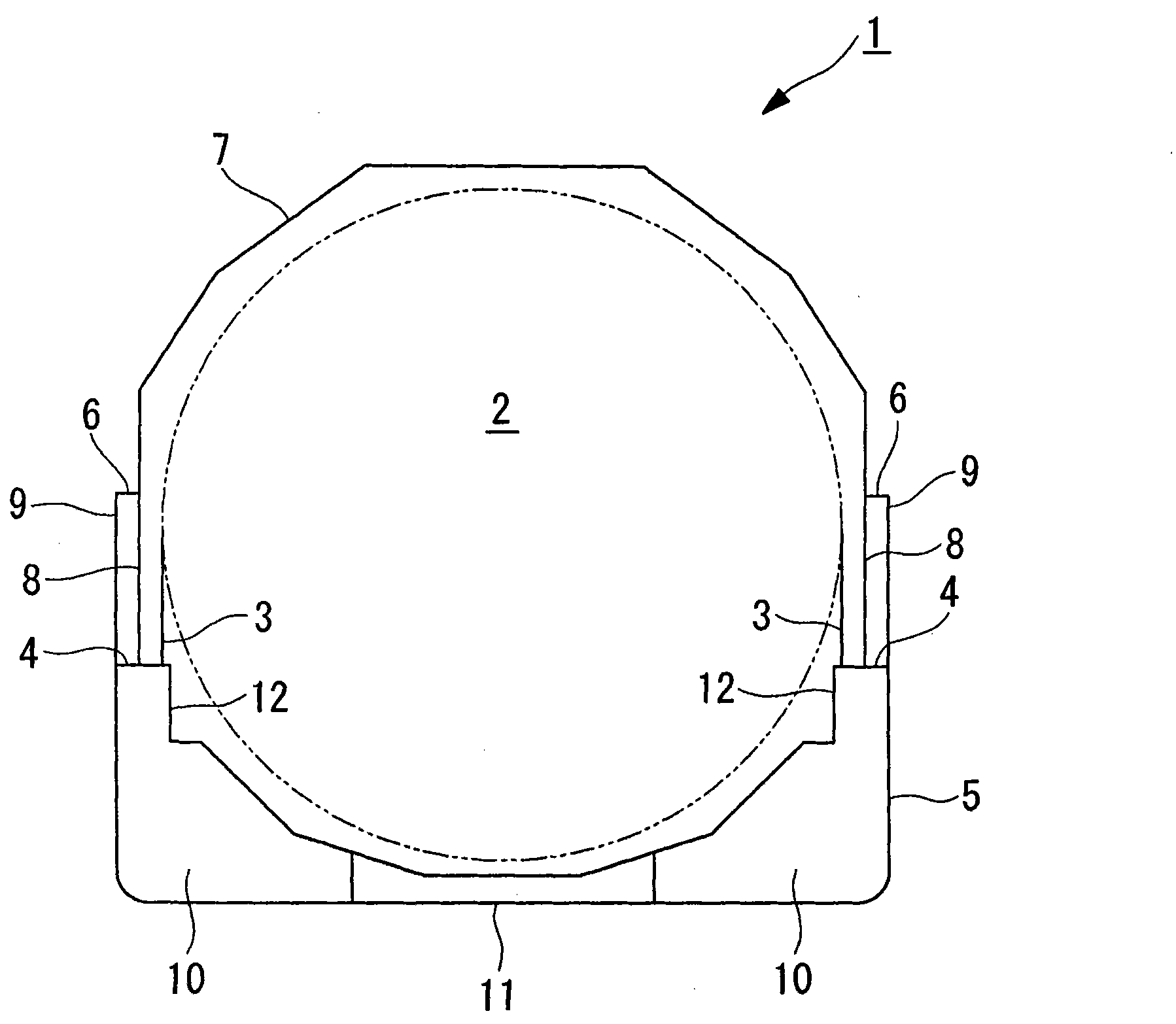

[0033] Below, refer to Figure 1A to Figure 4 One embodiment of the liquefied gas carrier of the present invention will be described.

[0034] Figure 1A It is the right side view of the liquefied gas carrier of this embodiment, Figure 1B It is a plan view of the liquefied gas carrier of this embodiment, figure 2 yes Figure 1A II-II to view the sectional view, Figure 3A It is a figure of the liquefied gas carrier of this embodiment, and it is Figure 1A A-A sectional view, Figure 3B It is a figure of the liquefied gas carrier of this embodiment, and it is Figure 1B The B-B direction section view, Figure 4 yes Figure 1A Section view of IV-IV direction.

[0035] Such as Figure 1A , Figure 1B and Figure 3A As shown, the liquefied gas carrier ("LNG ship" in this embodiment) 1 of this embodiment is, for example, a ship equipped with four aluminum spherical tanks (also referred to as "Moss type spherical tanks") 2, The spherical tank 2 made of aluminum is configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com