Process for production of molded polyester resin article, crystallization inducer for use in the process, master batch, and molded polyester resin article

A technology of polyester resin and production method, which is applied in the production of polyester resin plastic parts, masterbatch and polyester resin plastic parts, crystallization initiator field, can solve the problems such as the decrease of transparency of polylactic acid plastic parts, and achieve excellent compatibility , Excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] The kneaders usable in the preparation step of resin A, the preparation step of masterbatch M and the preparation of various mixtures in the present invention may include extruders such as single-screw extruders, twin-screw extruders, and multi-screw extruders. extruder, three-roll mill, two-roll mill, pressure kneader, Banbury mixer, open twin-screw continuous kneader, and the like, particularly preferably an extruder. In the molding step of plastic part D or E, screw extruders such as single-screw extruders, co-rotating or counter-rotating twin-screw extruders, and multi-screw extruders can be used; injection molding machines ; rotary kneaders; single-screw or multi-screw continuous kneaders; and the like.

[0094] These kneaders, molding machines and molding machines can be used alone or in combination by usual resin kneading or resin molding or molding methods. In these kneading machines, various parts such as a screw, a kneading disk, and a rotor can be selectivel...

Embodiment 1

[0104] (1) Preparation of resin A-1 (crystallization initiator)

[0105] To powder (100 g) of poly(L-lactic acid) (resin A', hereinafter referred to as "polylactic acid") was added t-butylperoxyisopropyl carbonate (purity: 95%; 0.4 g, 0.0022 mol). After thorough mixing, the resulting mixture was kneaded in a 25-mm twin-screw extruder (L / D: 42, kneading temperature: 200° C.), put into water in the form of strands and cooled therein, and then pelletized by Machine cut to prepare pellets of Resin A-1.

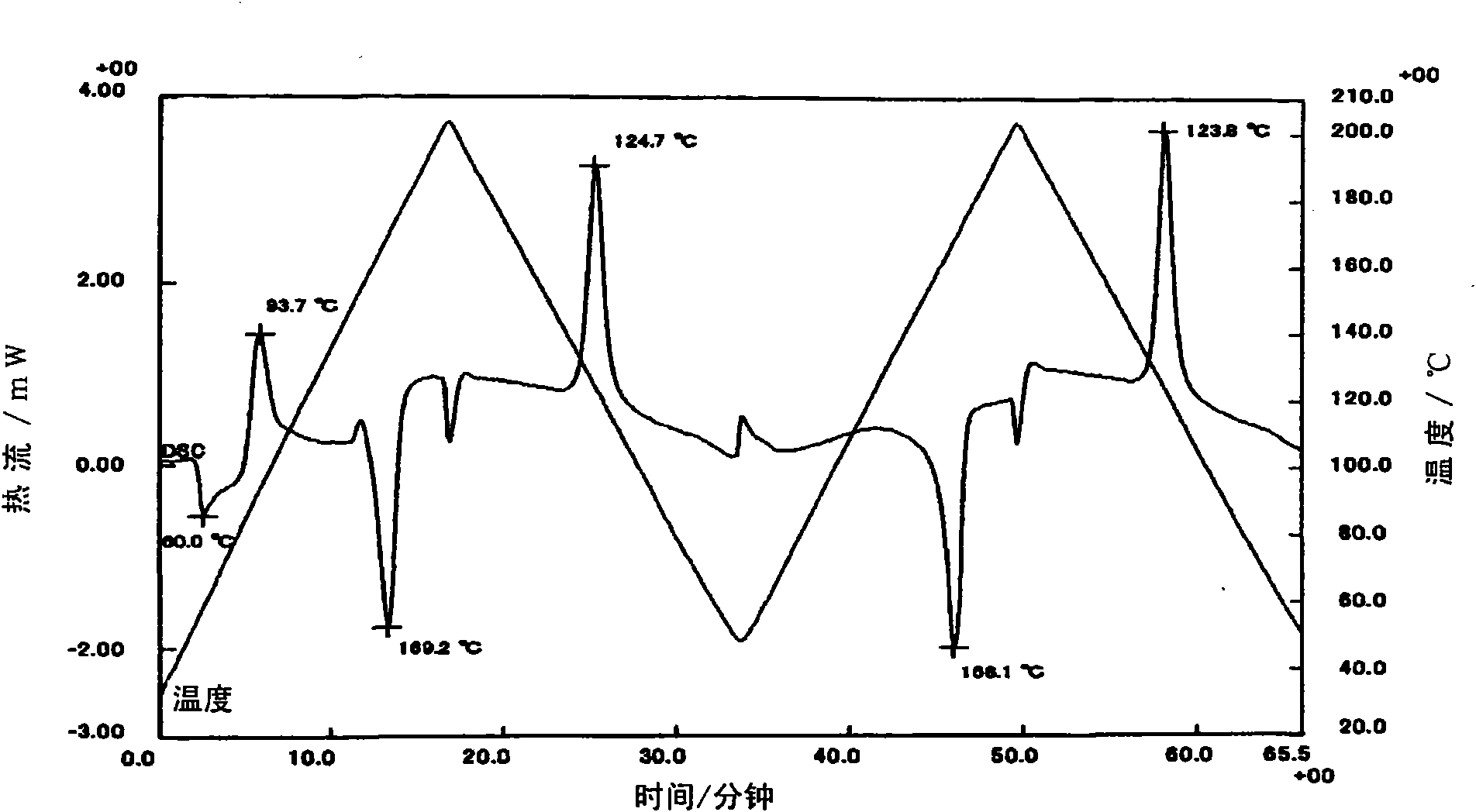

[0106] The differential scanning calorimetry measurement of the pellets of resin A-1 obtained as described above was carried out twice in succession. figure 1 A particle diagram of resin A-1 is shown. In the first measurement, a steep endothermic curve representing melting of the particles of resin A-1 with a peak at 169°C appeared upon heating, and a steep endothermic curve representing crystallization of the particles of resin A-1 appeared at 125°C upon cooling. exothermic p...

Embodiment 2-4

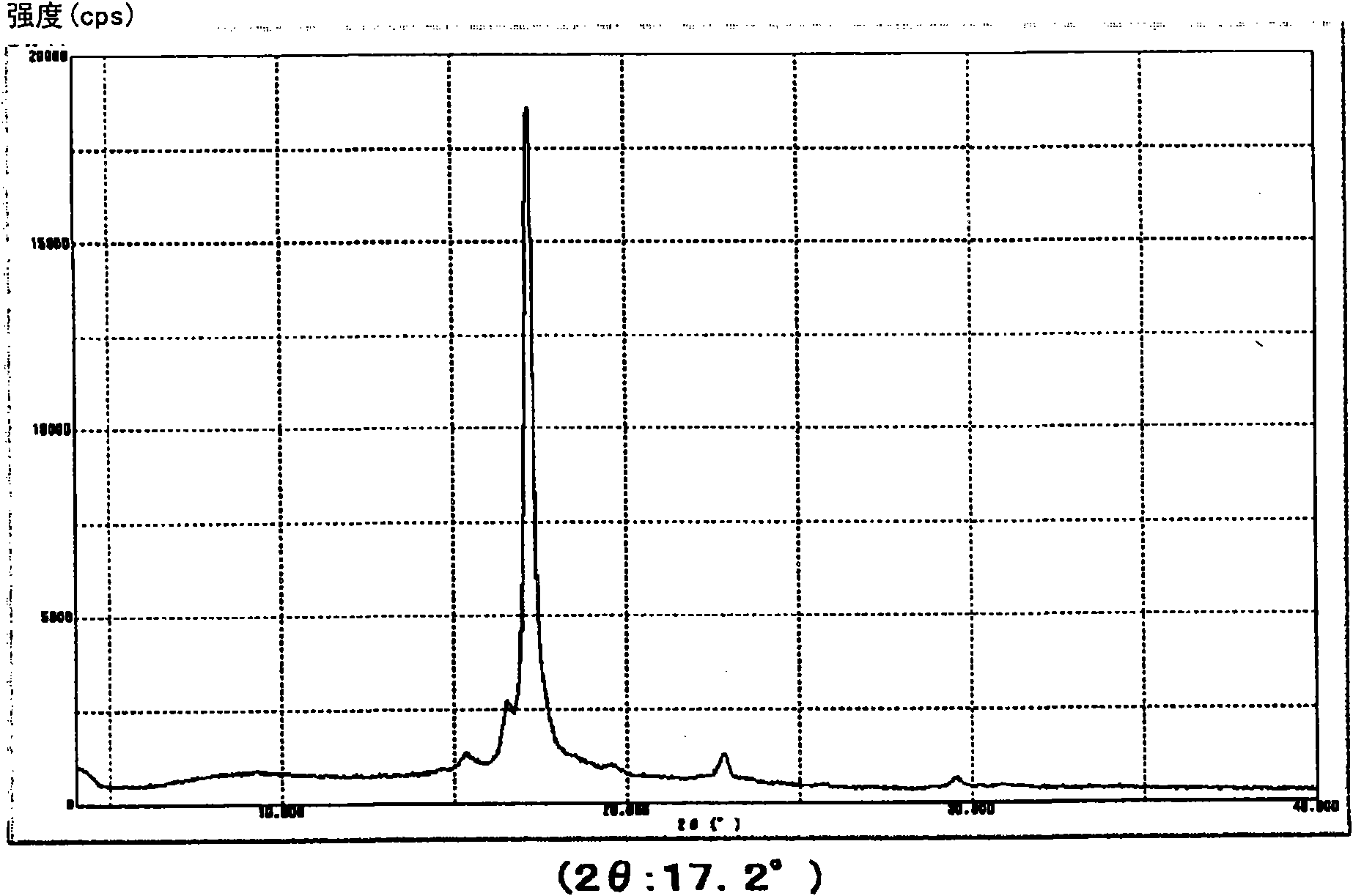

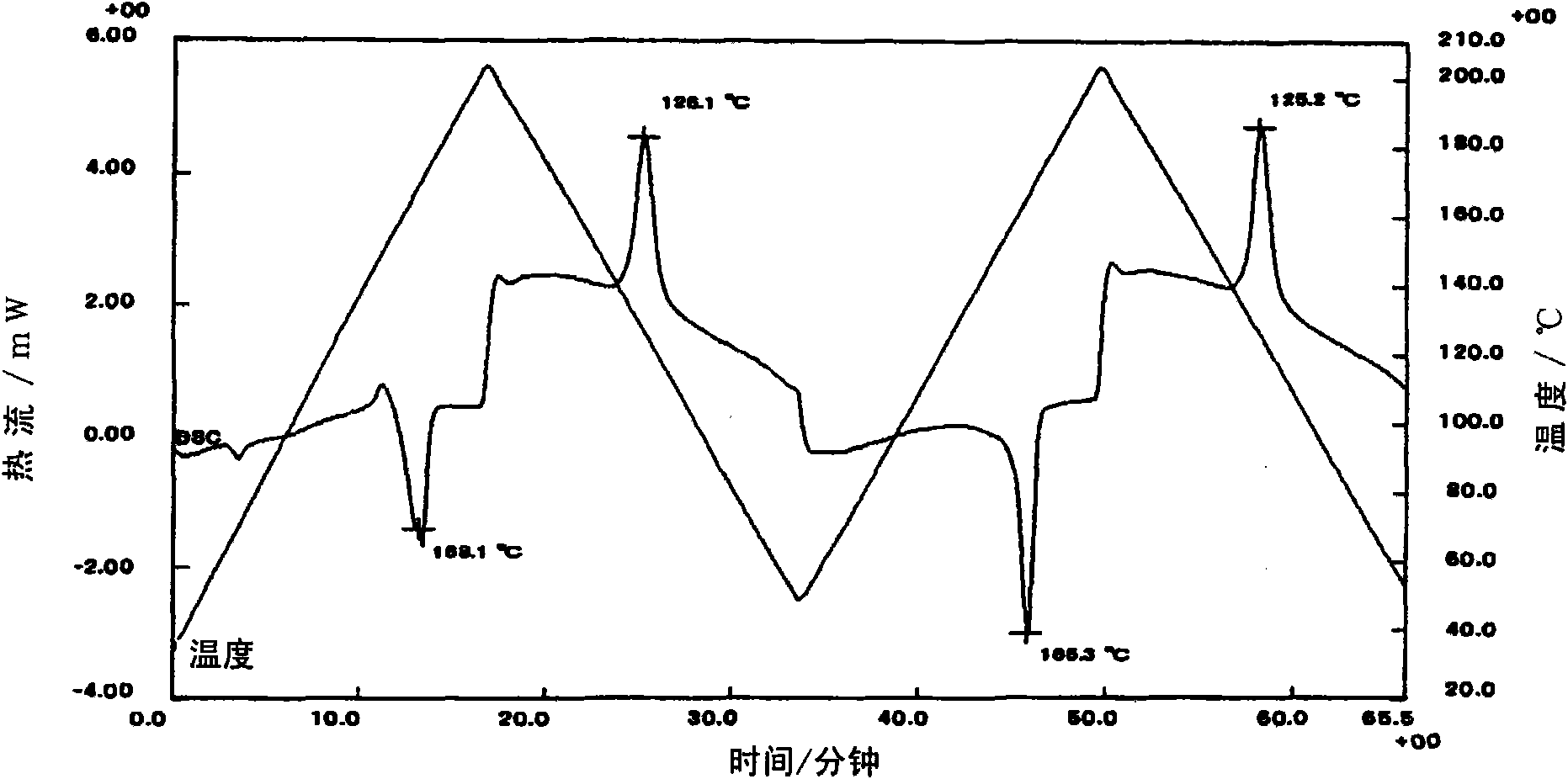

[0114] In a similar manner to Example 1(3), an aliquot of pellets of masterbatch M-1 and an aliquot of pellets of polylactic acid (resin C) were mixed as shown in Table 4, respectively. The resulting mixture was molded by an injection molding machine alone to obtain molded plates D-2 to D-4 of polylactic acid. Differential scanning calorimetry and X-ray diffraction were performed on the molded plate thus obtained. Table 4 shows the exothermic peak temperature upon cooling and the peak angle 2θ in the X-ray diffraction pattern.

[0115] Table 4

[0116]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com