Ultrasonic continuous sterilization device and method thereof

A sterilization device and ultrasonic technology, applied in the field of juice sterilization and ultrasonic continuous sterilization device, can solve the problems of high production cost, large energy consumption, small processing capacity, etc., and achieve the effects of simple structure, reduced production cost and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

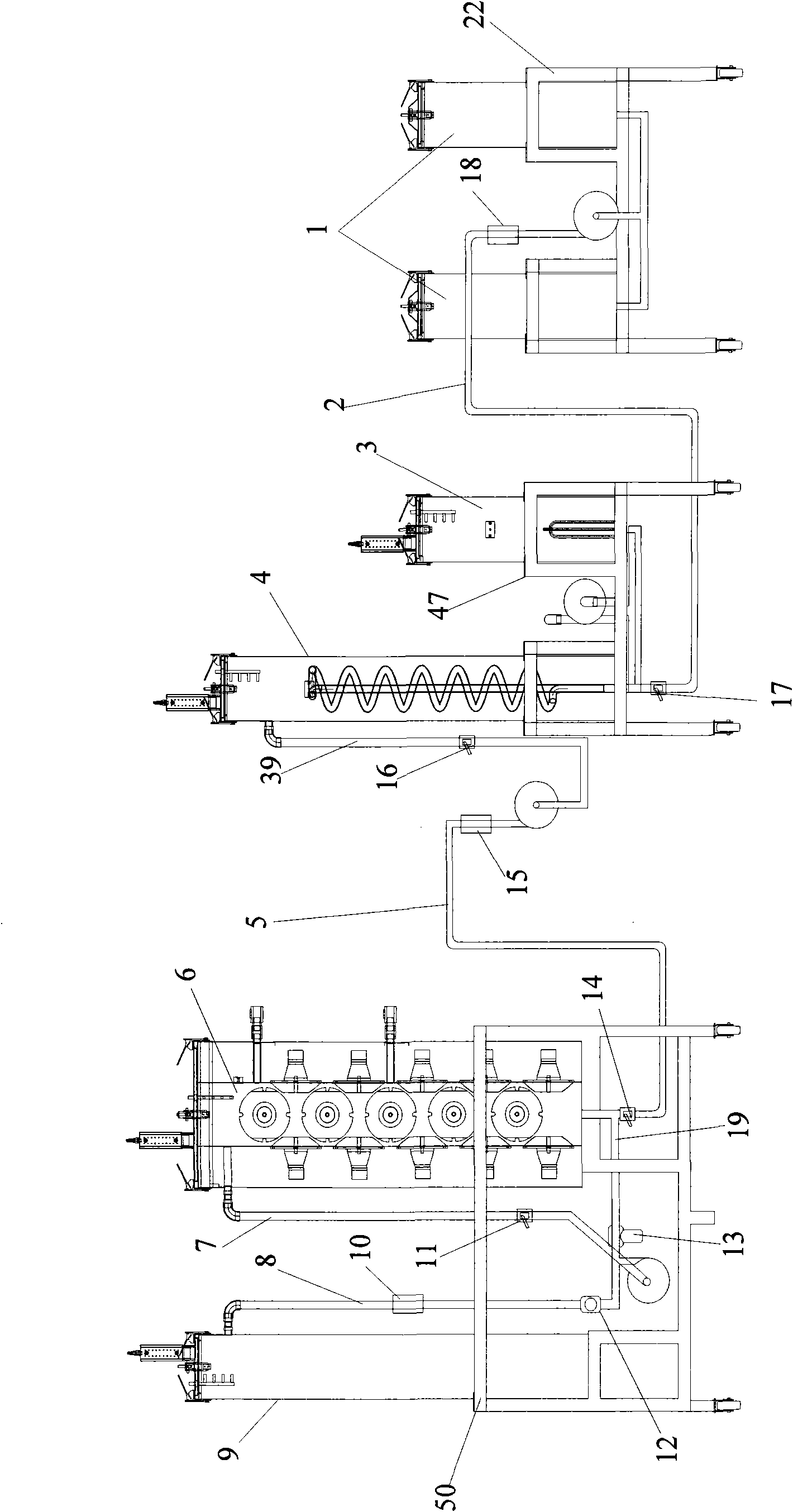

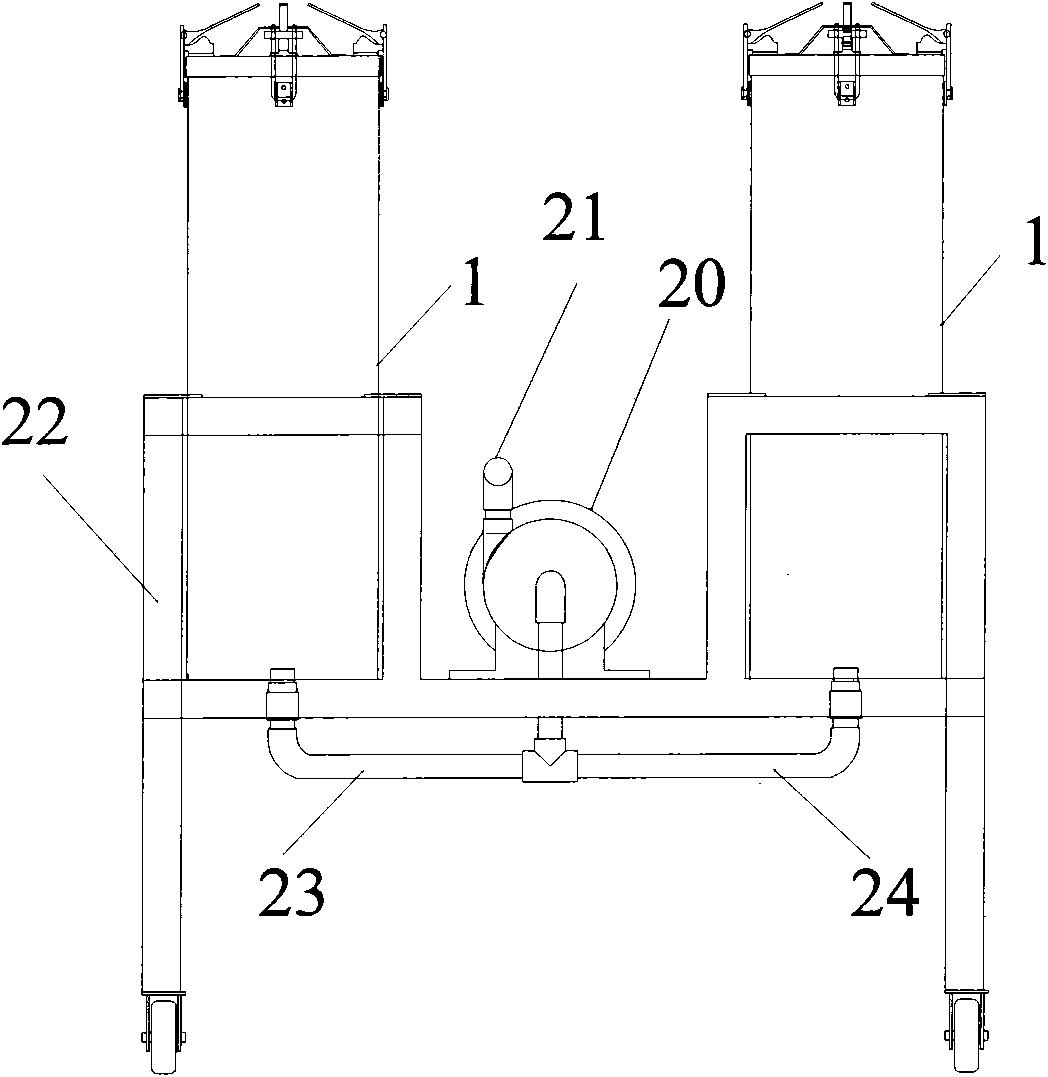

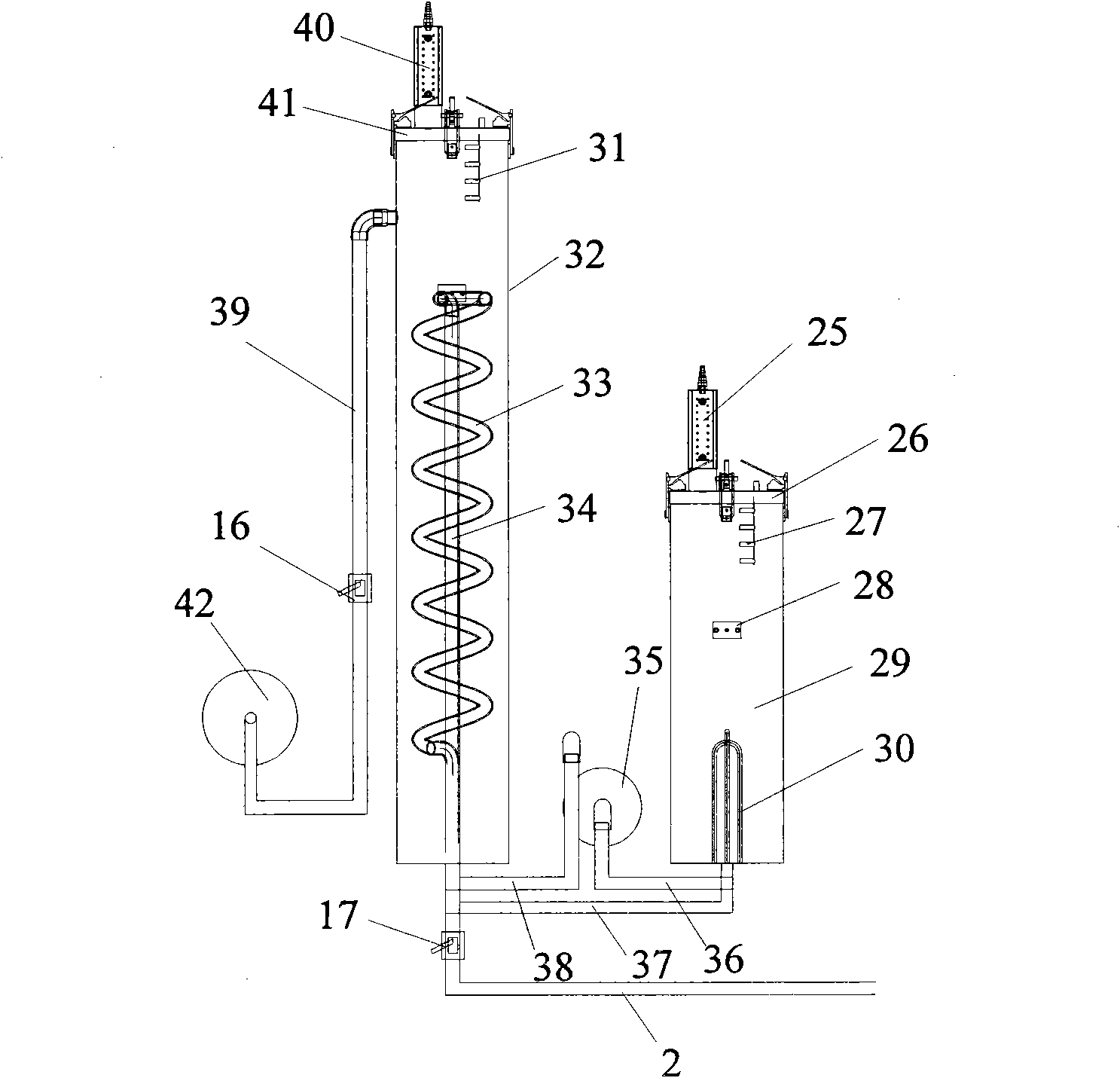

[0054] Figure 1 to Figure 6 Shows the specific structural schematic diagram of this embodiment, such as figure 1 As shown, the ultrasonic continuous sterilization device includes a controller, a raw material tank 1, a heating device 3, a heat exchange device 4, an ultrasonic processing device 6, a liquid storage device 9, a support one 22, a support two 47 and a support three 50, the heating The device 3 is connected to the heat exchange device 4, and the raw material tank 1, the heat exchange device 4, the ultrasonic treatment device 6 and the liquid storage device 9 are connected through pipelines 2, 39, 5, 7, and 8 in sequence; figure 1 As shown, the raw material tank 1 is fixed on the first bracket 22, the heating device 3 and the heat exchange device 4 are fixed on the second bracket 47, and the ultrasonic processing device 6 and the liquid storage device 9 are fixed on the third bracket 50. The controller is respectively connected to the control valve on the heating de...

Embodiment 2

[0090] This embodiment is the same as Embodiment 1 except for the following features: the flow rate of the feed liquid between the raw material tank, heating device, heat exchange device, ultrasonic treatment device and liquid storage device is 60L / h;

[0091] In the step (2), the temperature of the hot water input by the heating device to the heat exchange device 4 is 80°C;

[0092] In the step (2), the feed temperature of the feed liquid flowing into the heat exchange device is 10°C, and the discharge temperature of the feed liquid flowing out from the discharge port is 50°C; the heat exchange time of the feed liquid in the heat exchange device 10min;

[0093] In the step (3), the dynamic ultrasonic sterilization time of the feed liquid in the ultrasonic tank is 10 minutes.

[0094] In the step (2-2), the temperature of the hot water in the heating barrel is maintained at 80° C.; in the step (2-3), the time for the hot water in the heat exchange barrel is 10 minutes.

[00...

Embodiment 3

[0097] This embodiment is the same as Embodiment 1 except for the following features: the flow rate of the feed liquid between the raw material tank, the heating device, the heat exchange device, the ultrasonic processing device and the liquid storage device is 120 L / h;

[0098] In the step (2), the temperature of the hot water input by the heating device to the heat exchange device 4 is 95°C;

[0099] In the step (2), the feed temperature of the feed liquid flowing into the heat exchange device is 20°C, and the discharge temperature of the feed liquid flowing out from the discharge port is 60°C; the heat exchange time of the feed liquid in the heat exchange device 20min;

[0100] In the step (3), the dynamic ultrasonic sterilization time of the feed liquid in the ultrasonic tank is 20 minutes.

[0101] In the step (2-2), the temperature of the hot water in the heating barrel is kept at 95° C.; in the step (2-3), the time for the hot water in the heat exchange barrel is 20 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com