Vertical spiral pressurized sludge granulator

A granulator and sludge technology, which is applied in the direction of raw material extrusion granulation, dehydration/drying/thickened sludge treatment, etc., can solve the problems of unstable granulation, low continuous operation rate, and lack of equipment, etc., to achieve Stable curing results, easy operation, and improved continuous operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

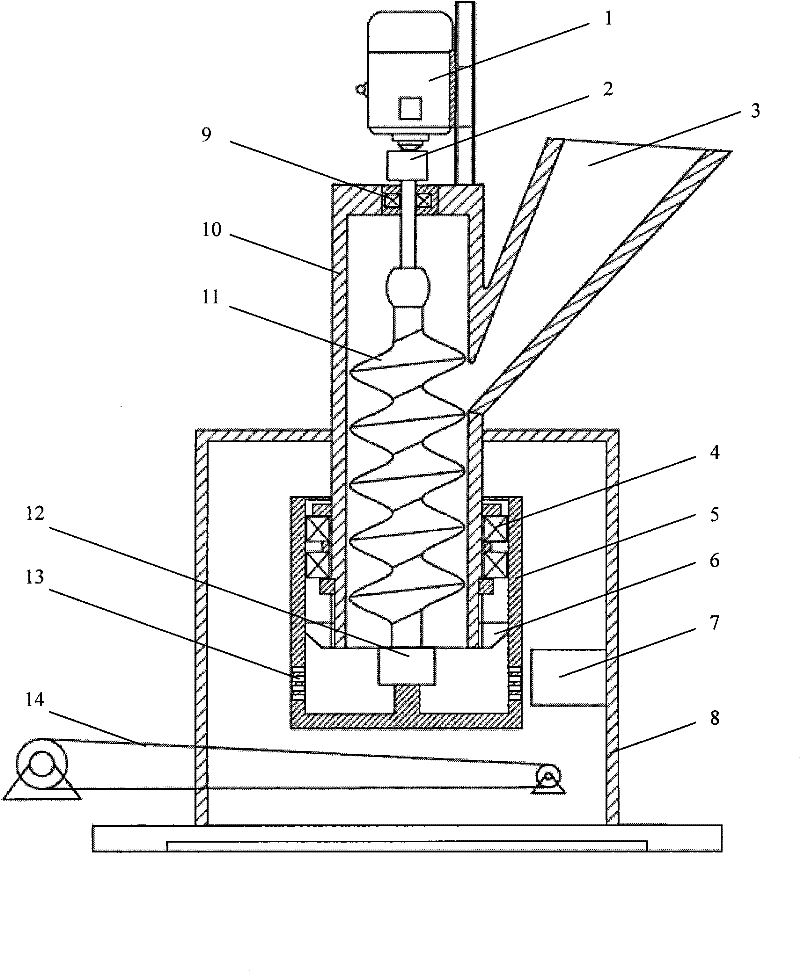

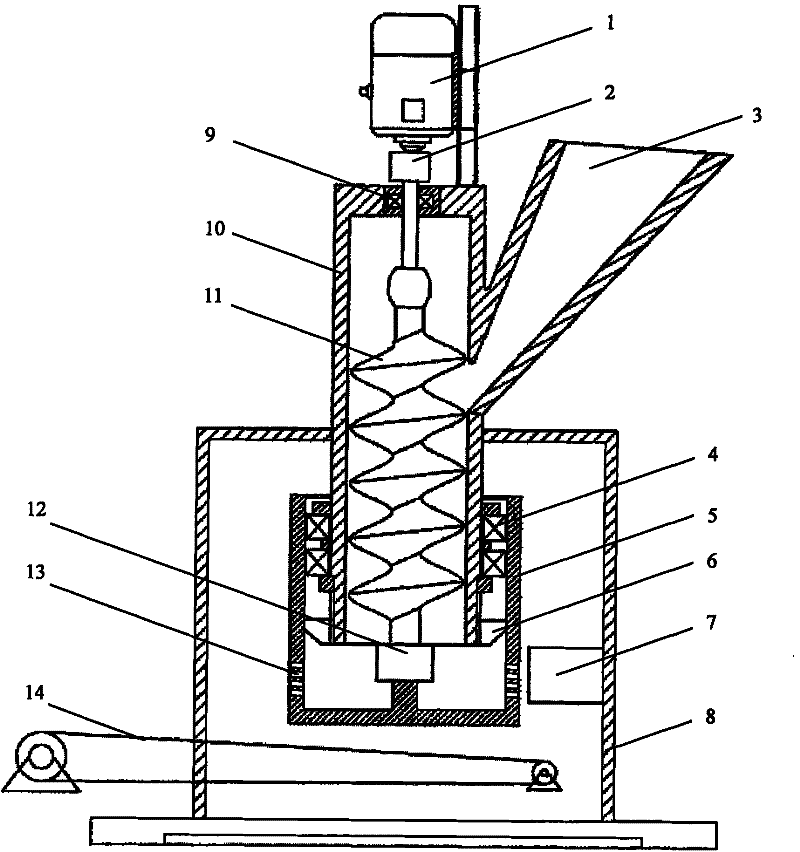

[0009] A vertical screw pressurized sludge granulator of the present invention is further described in detail below in conjunction with the accompanying drawings: the sludge granulator is composed of a bracket 8, a granulation device, a belt conveyor 14, a scraper 7, etc., and the granulation device Consists of motor 1, shaft coupling 2, main thrust bearing 9, pressurized screw rod 11, main working cylinder 10, grain rejection head bearing 4, shaft seal nut 6, rotary grain rejection head 5, deceleration rotary disk 12 and constitutes. The granulation device is vertical and fixed on the support 8, the main working cylinder 10 is a cylindrical container with an open lower end, and the inner wall of the main working cylinder 10 is provided with a double-closed helical stator corresponding to the helical blade of the pressurizing screw rod 11. The double-closed spiral stator is used to cooperate with the pressurized screw 11 to squeeze and transmit the mud, and the shaft seal round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com