Method and equipment thereof for buckling-riveting outer sleeve of push-pull flexible shaft

A push-pull, outer tube technology, applied in the field of push-pull flexible shaft outer tube riveting and its equipment, can solve the problems of one-way punching riveting punching force, deformation of the inner hole of the lining tube, short service life of the push-pull flexible shaft, etc., and achieve smooth movement. , Good riveting degree, not easy to cross deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing of description:

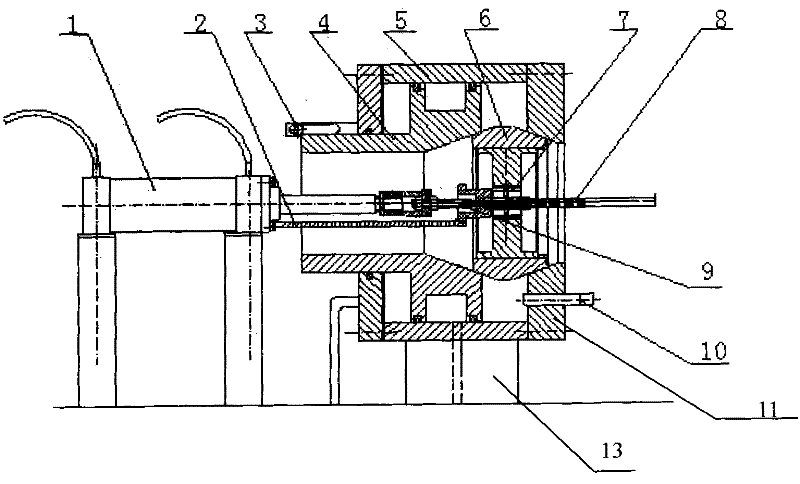

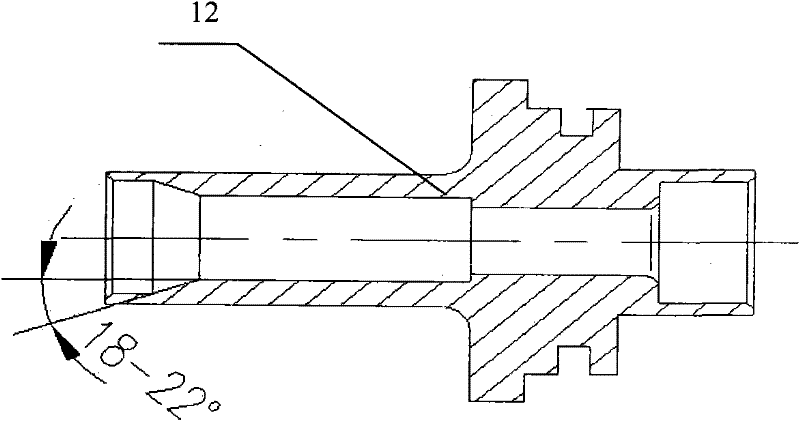

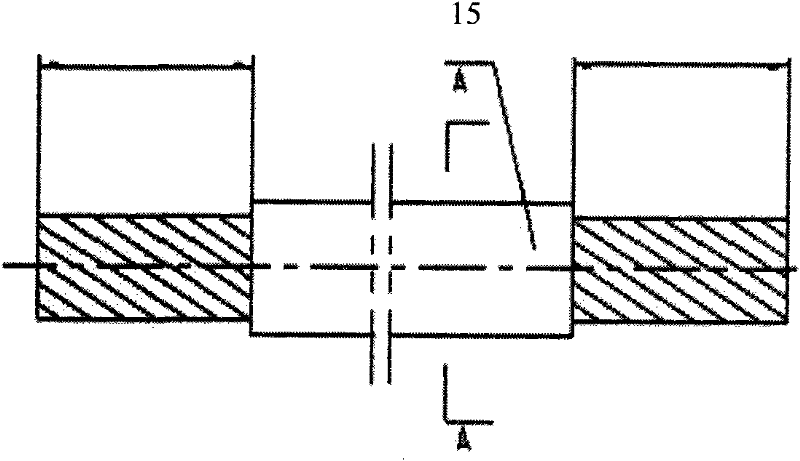

[0027] Such as figure 1 As shown, the equipment specially designed for implementing a push-pull flexible shaft outer tube buckle riveting method includes a hydraulic system, an air pressure system, a buckle riveting mold, a frame, etc., and the hydraulic cylinder 5 is axially arranged and fixed on the frame 13. The buckle riveting die includes an outer mold 4 with an inner taper hole and an elastic die set 6 whose outer tapered surface matches the inner taper hole of the outer die. The elastic die set 6 is fixed on the frame or the cylinder block The upper block 11 is in contact with each other, and the taper of the inner taper hole of the outer mold is 25°-65°. The elastic die set 6 is composed of 6-16 die sets and die sets 7, and springs 14 are installed between each die set. , the crimping surface of the die piece 7 in contact with the casing joint 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com