Heat treatment method for materials of 25CrMo alloy steel hollow car axle for high-speed railway passenger trains

A heat treatment method, high-speed railway technology, applied in the direction of heat treatment furnace, heat treatment equipment, furnace type, etc., can solve the problem that the key heat treatment process technology for manufacturing axles is not given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

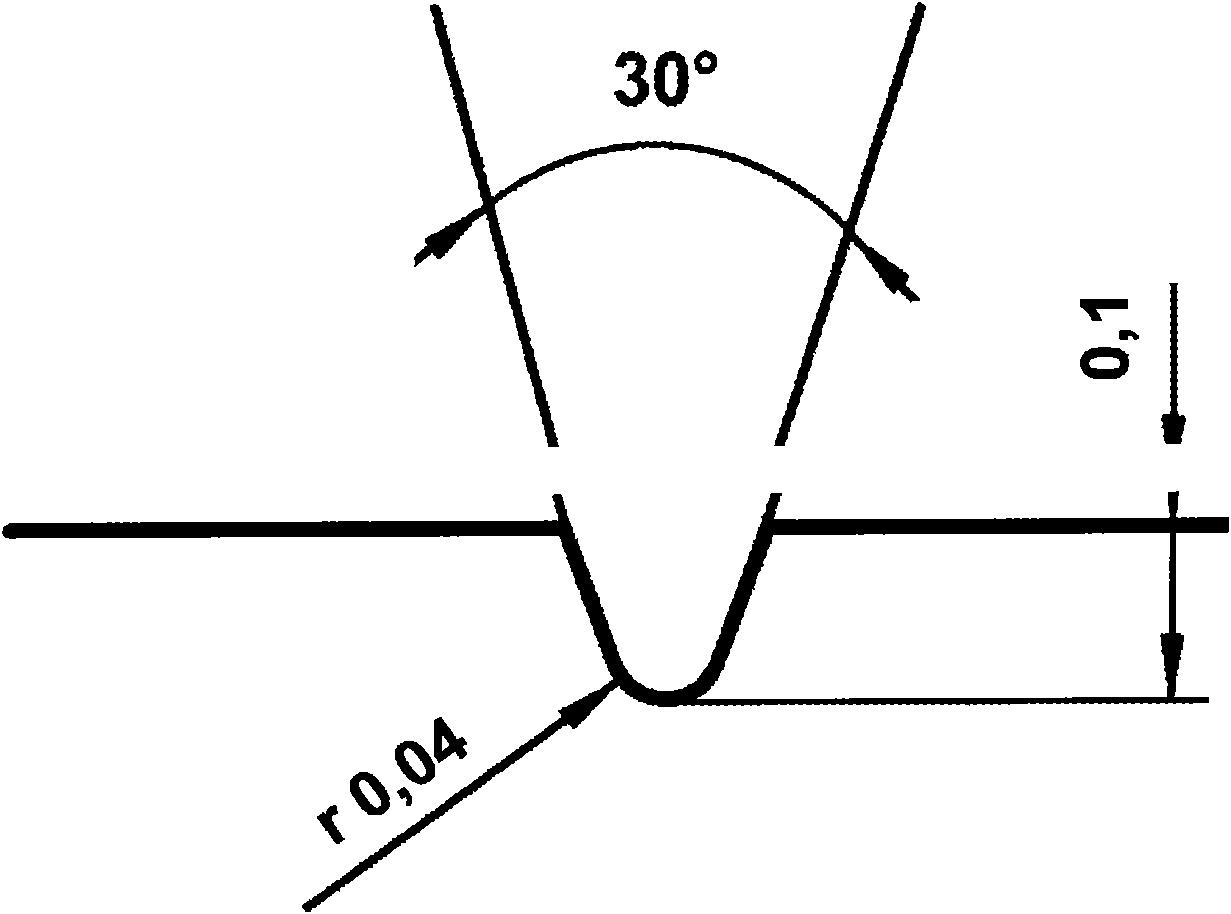

[0018] At 920°C, hold for 4 hours and then air cool, then hold at 900°C for 4 hours and then water quench, and hold at 640°C for 6 hours and then air cool.

Embodiment 2

[0020] At 910°C, hold for 4 hours and then air cool, then hold at 910°C for 5 hours and then water quench, and hold at 650°C for 6 hours and then air cool.

Embodiment 3

[0022] 920°C, keep warm for 3 hours, then air cool, then keep warm at 920°C for 3 hours, then water quench, keep warm at 650°C for 6 hours, then air cool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com