Method for processing plating layer on inner wall of oil tank and device thereof

A processing method and fuel tank technology, applied in the field of processing and manufacturing, can solve problems affecting the internal corrosion resistance of the tank, shorten the service life of the fuel tank, etc., and achieve the effects of prolonging the service life, enhancing corrosion resistance and corrosion resistance, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

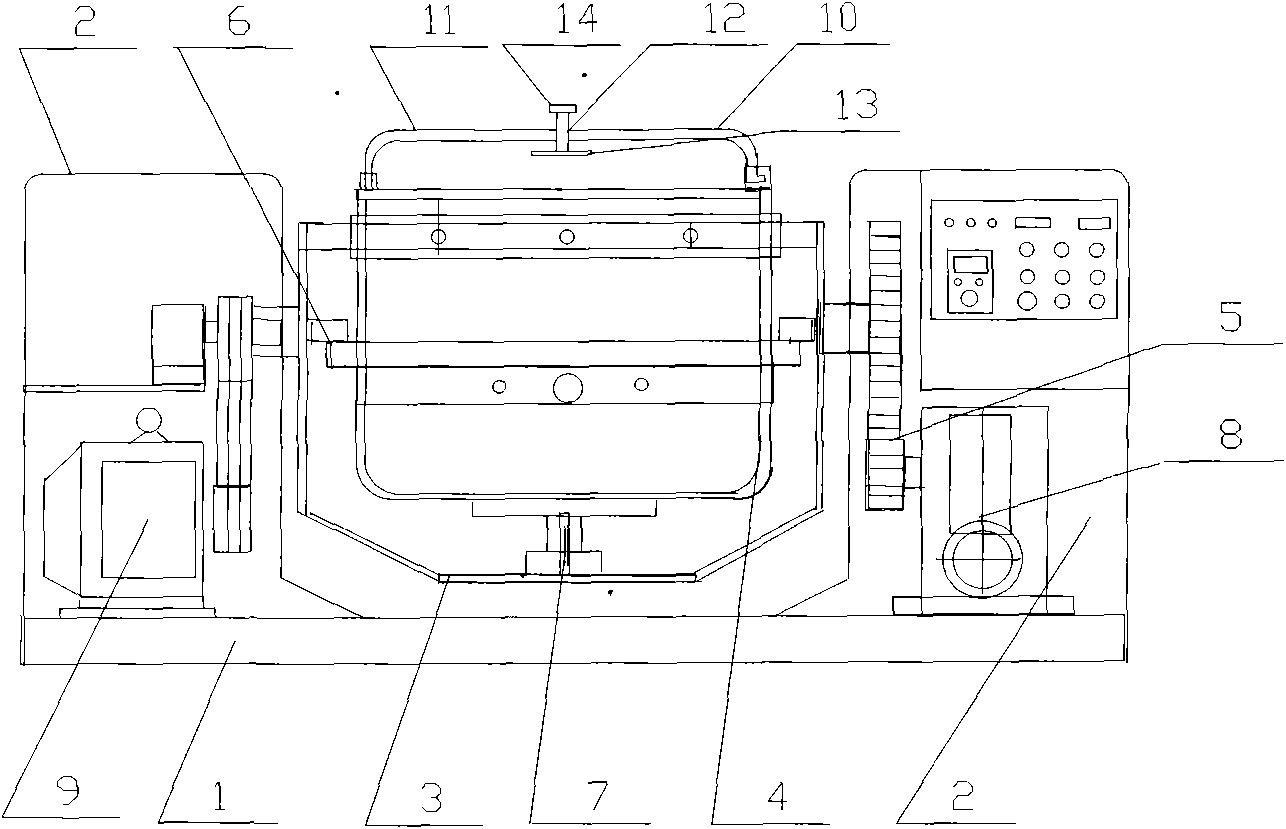

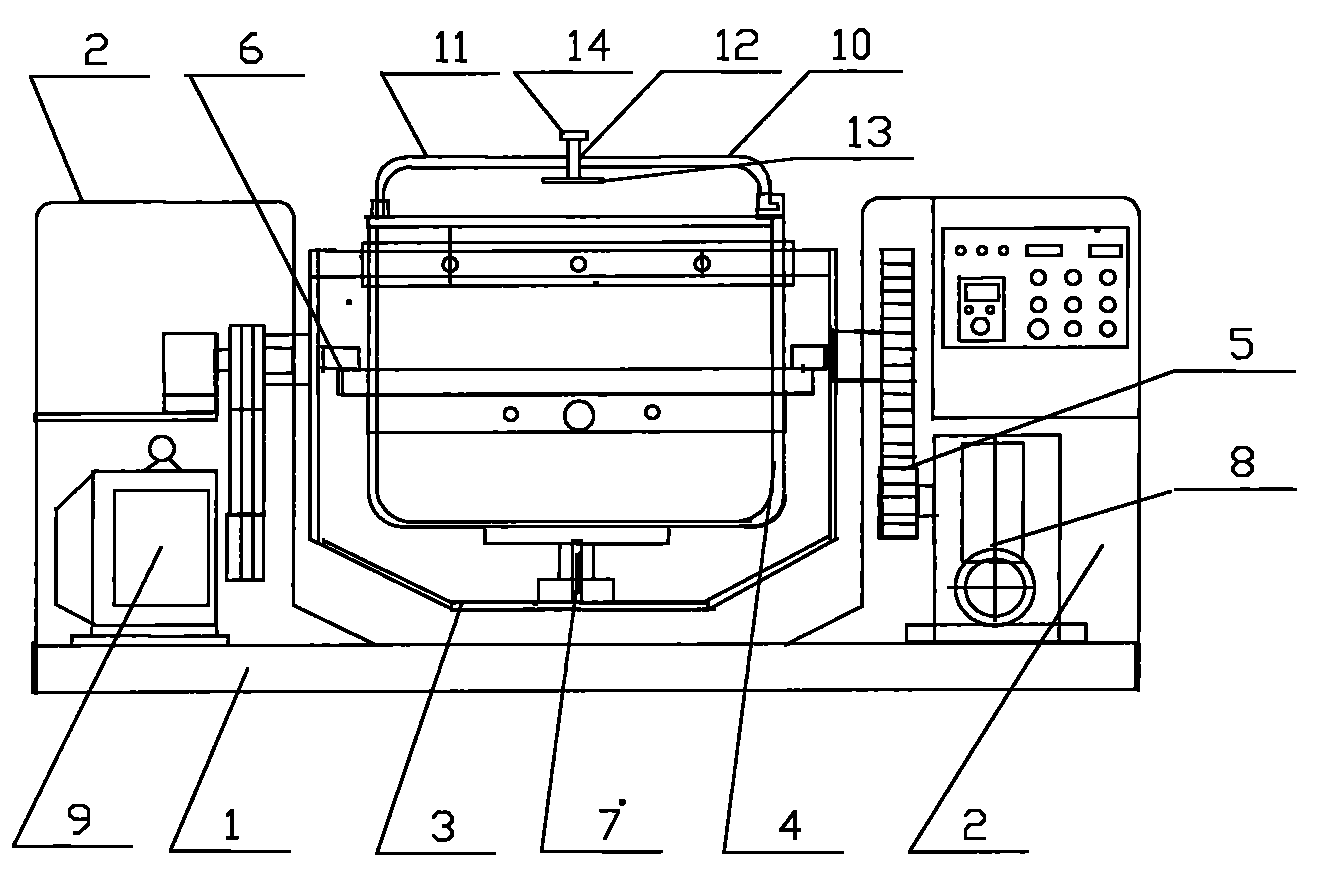

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The invention relates to a coating processing method for the inner wall of an oil tank. Firstly, the oil tank is integrally welded, and then the inner wall of the oil tank is subjected to barrel plating of a zinc alloy coating, wherein the barrel plating step of the zinc alloy coating is carried out in a turning device. After the welding process of the whole tank, the surface treatment of the inner wall of the fuel tank is carried out first, and impurities such as oxide skin and rust on the inner surface of the fuel tank are removed by chemical pickling method, after pickling for 10 to 15 minutes, the inside is washed twice with clean water, and then the following steps are carried out: Barrel plating steps of zinc alloy coating:

[0028] a. Add impact medium (glass beads) and water into the box, and the water volume accounts f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com