Determination method and device for dry cleaning time and plasma processing apparatus

A technology of dry cleaning and determination method, which is applied in the field of plasma, can solve the problems of shortening the service life of equipment, reducing production efficiency, prolonging cleaning time, etc., and achieve the effect of improving system production efficiency, prolonging service life and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

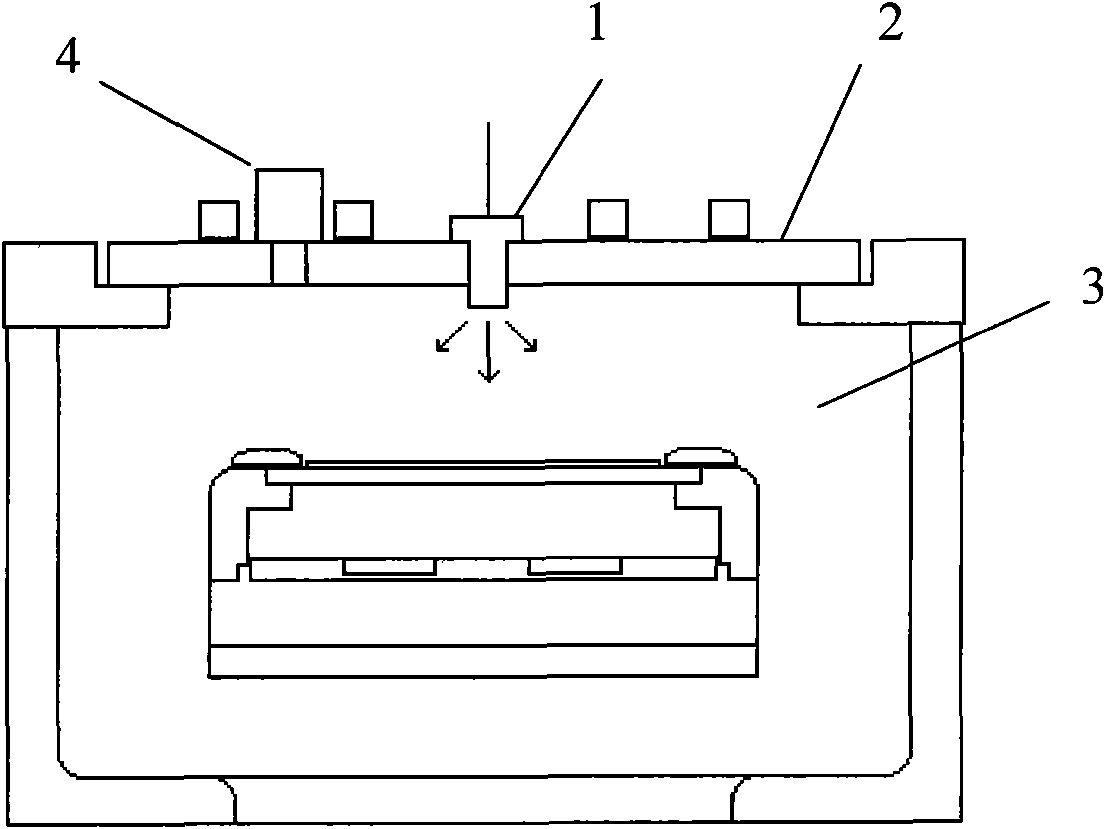

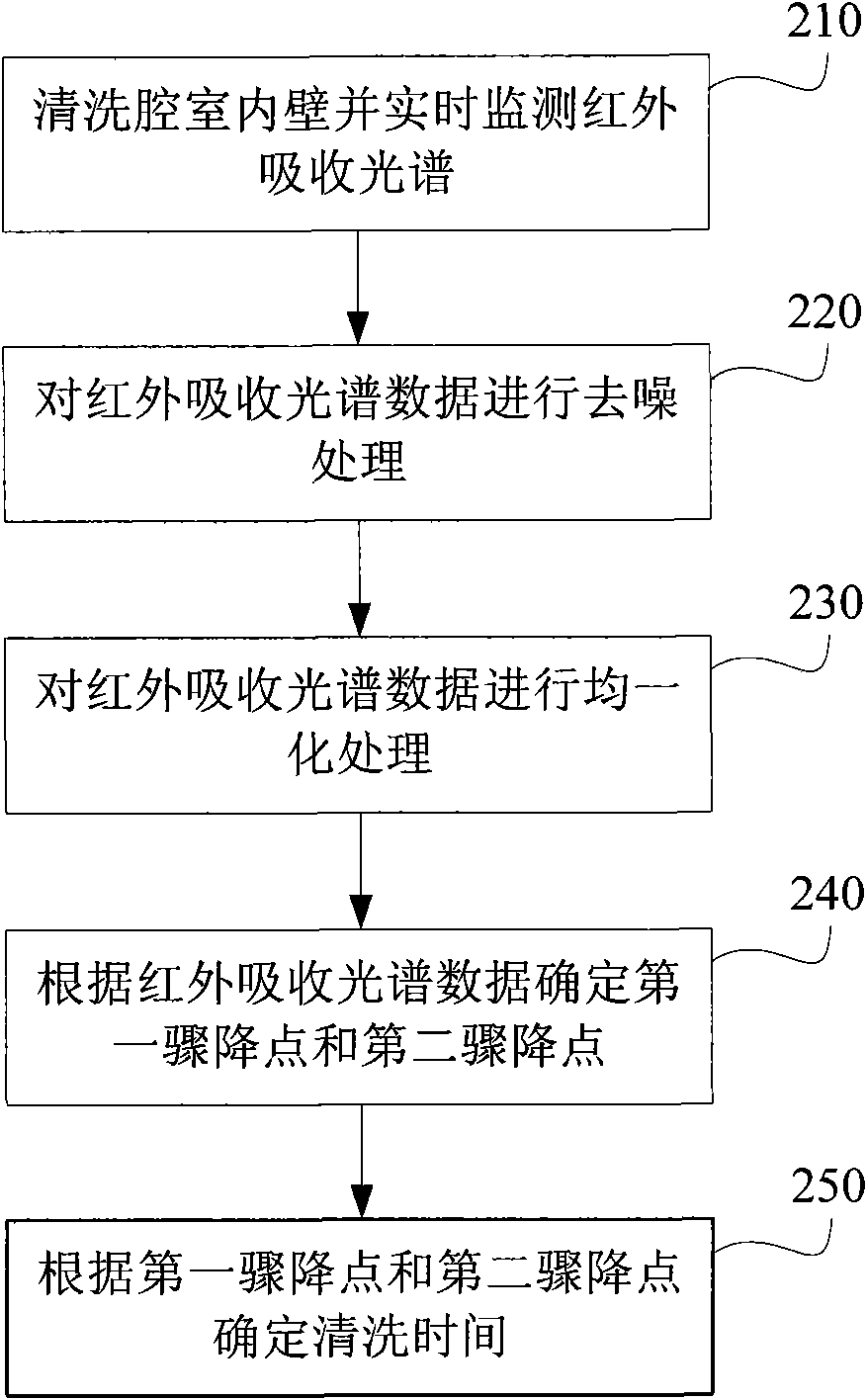

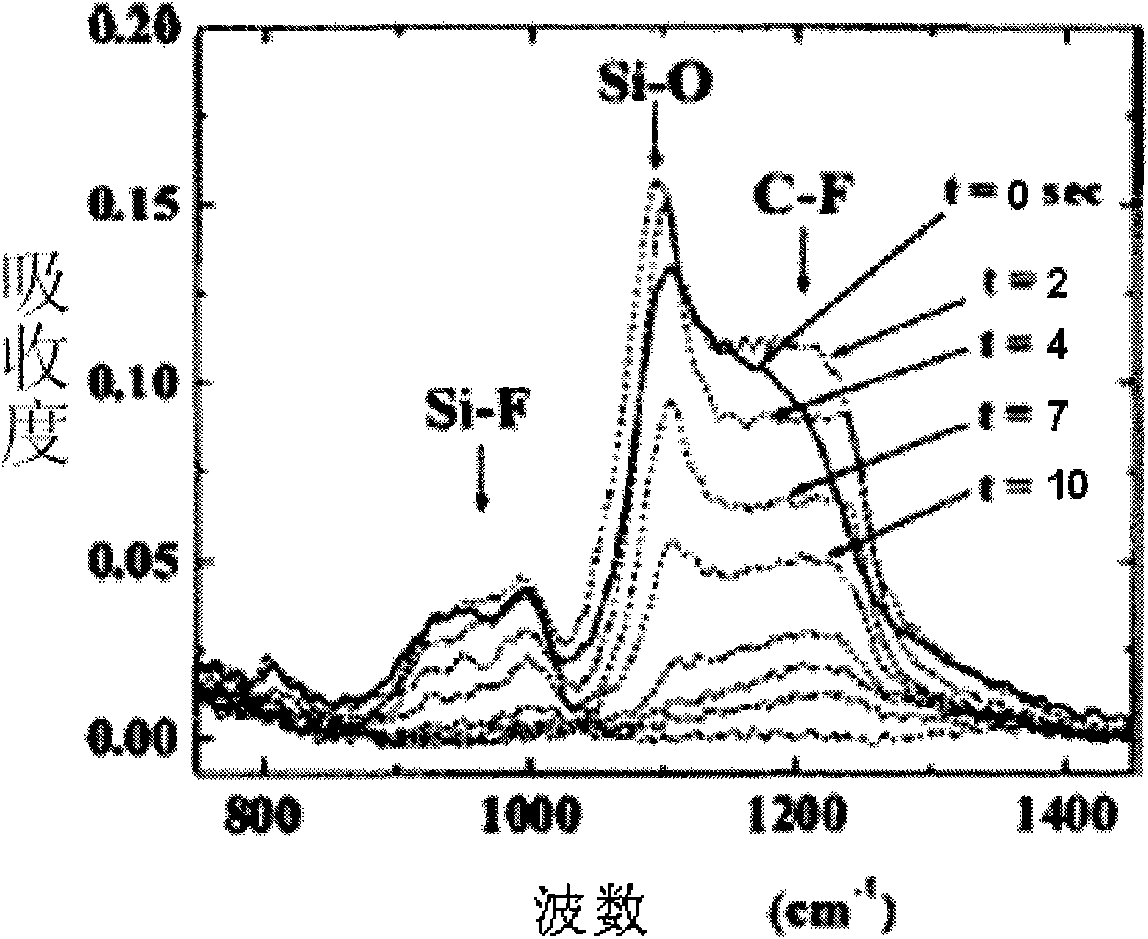

[0040]The core of the present invention is: utilize the characteristic that different compounds all have the inherent infrared absorption wavelength corresponding to its characteristic, and adopt the infrared spectrometer to monitor the infrared absorption spectrum of the deposit on the process chamber inner wall in real time, and in the first infrared absorption spectrum A time point is selected between the time point corresponding to the sudden drop point and the time point corresponding to the second sudden drop point, and it is used as the end time point for the cleaning process of the purge gas. It should be pointed out here that the inner wall of the chamber mentioned in this application includes the side wall of the chamber, the quartz window above the chamber, and the like.

[0041] In order for those skilled in the art to better understand the technical solution of the present invention, the following will take a plasma processing device with a plasma process chamber a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com