Surge-resisting and anti-static light-emitting diode and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of circuits, electrical components, and electric solid-state devices, and can solve problems such as complex procedures, high manufacturing costs of light-emitting diodes, and reduced performance of light-emitting diodes in eliminating static electricity, so as to achieve simple procedures and improve protection breakthroughs. Waves and static electricity, increase the efficiency of eliminating surges and static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

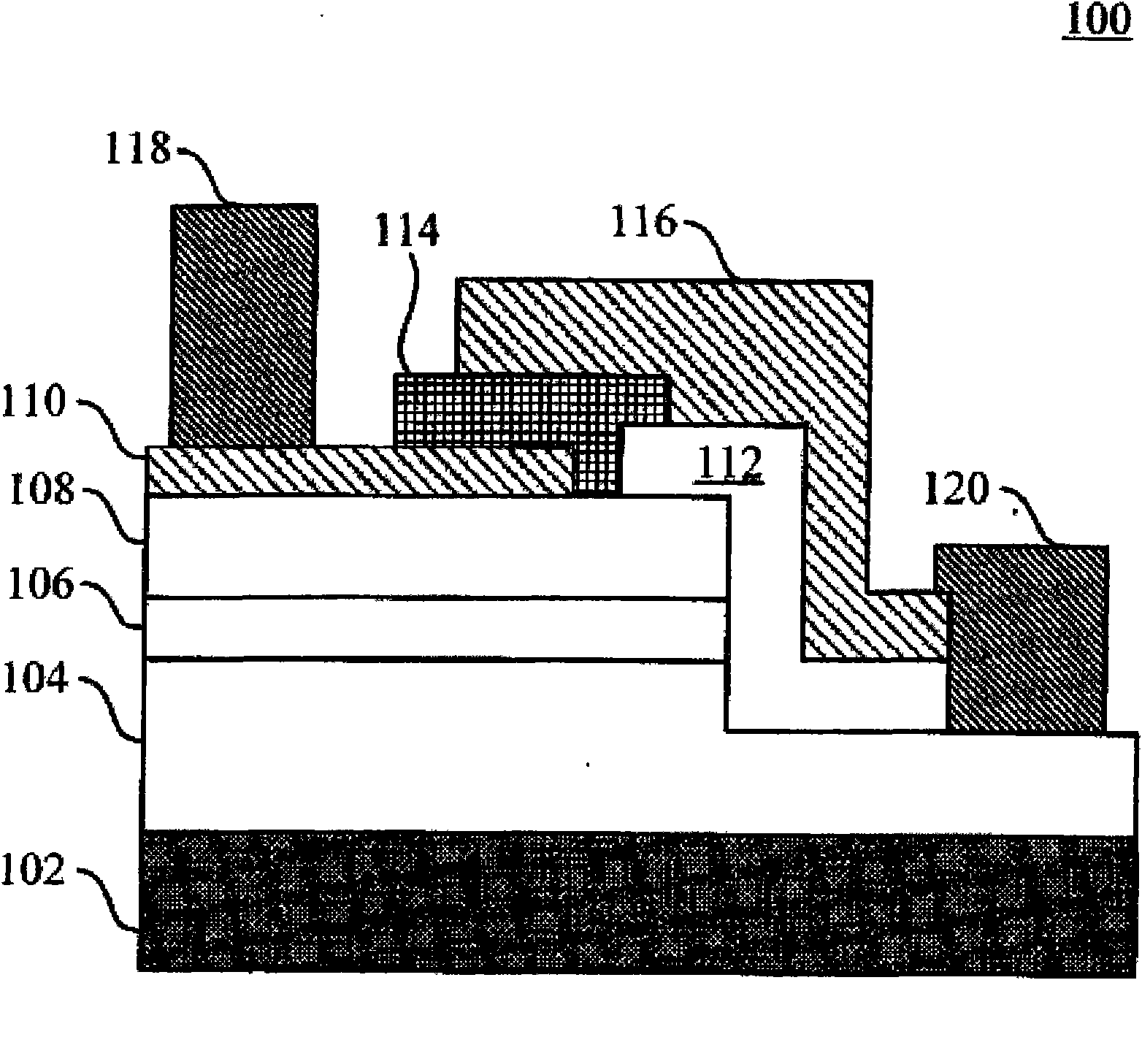

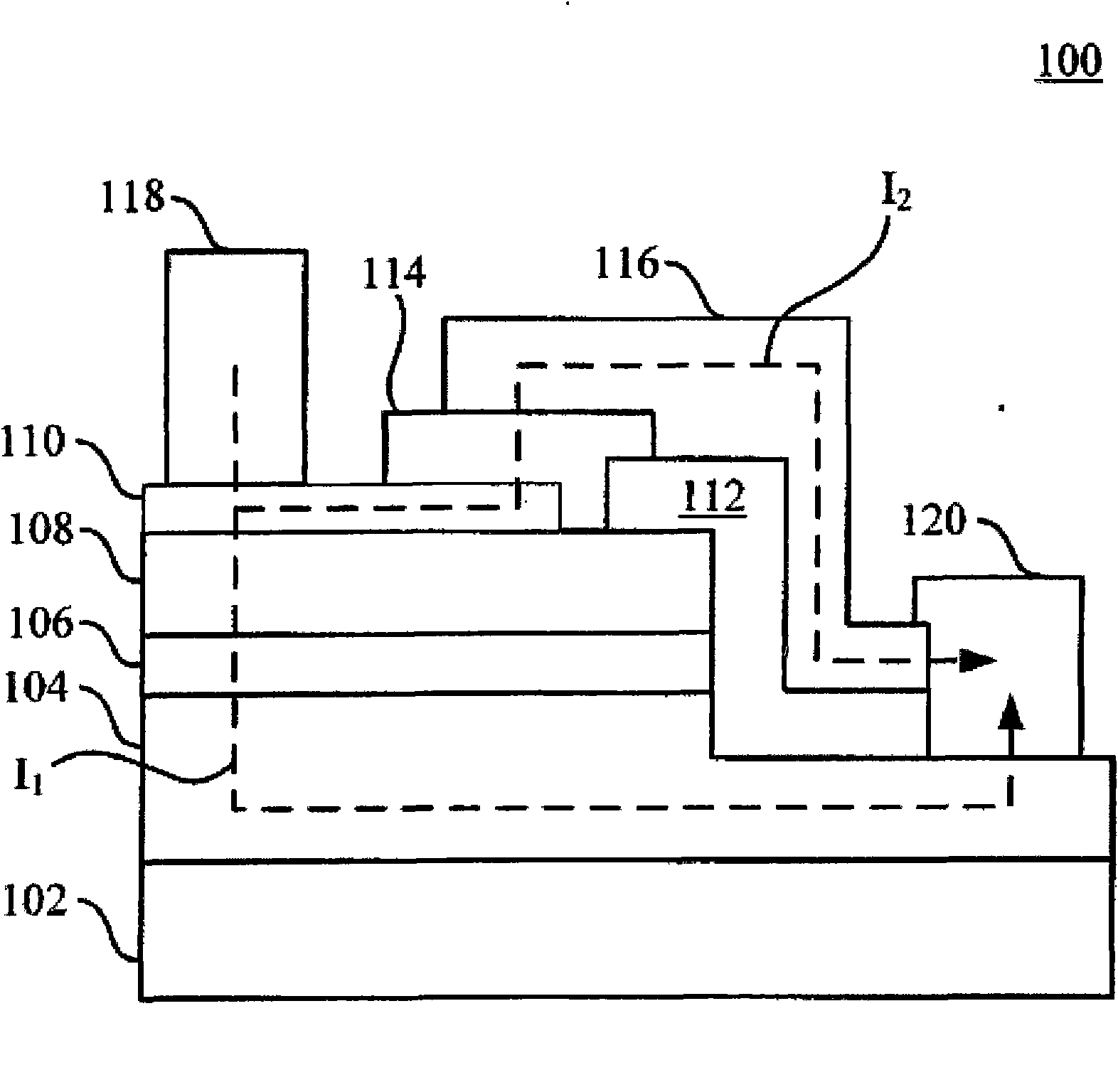

[0036] In the present invention, an oxide layer is formed on a diode chip, and when the diode receives a bias voltage exceeding the operating voltage, the oxide layer is used to promote the surge current derived from the bias voltage from the negative electrode through the second transparent conductive layer, oxidation Layer and the first transparent conductive layer conduct to the positive electrode and then lead out or conduct from the positive electrode to the negative electrode through the first transparent conductive layer, oxide layer and second transparent conductive layer and then lead out, so that the light-emitting diode can avoid the influence of surge and static electricity .

[0037] See figure 2 , is a side view of a light emitting diode according to a preferred embodiment of the present invention. As shown in the figure, the light emitting diode 100 of the present invention comprises a substrate 102, an N-type semiconductor layer 104, an active layer 106, a P-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com