Robot for polling transmission line

A technology for transmission lines and robots, which is applied in the directions of overhead lines/cable equipment, manipulators, manufacturing tools, etc., can solve the problems of non-existence, and achieve the effect of simple structure, stable application of force and stable force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

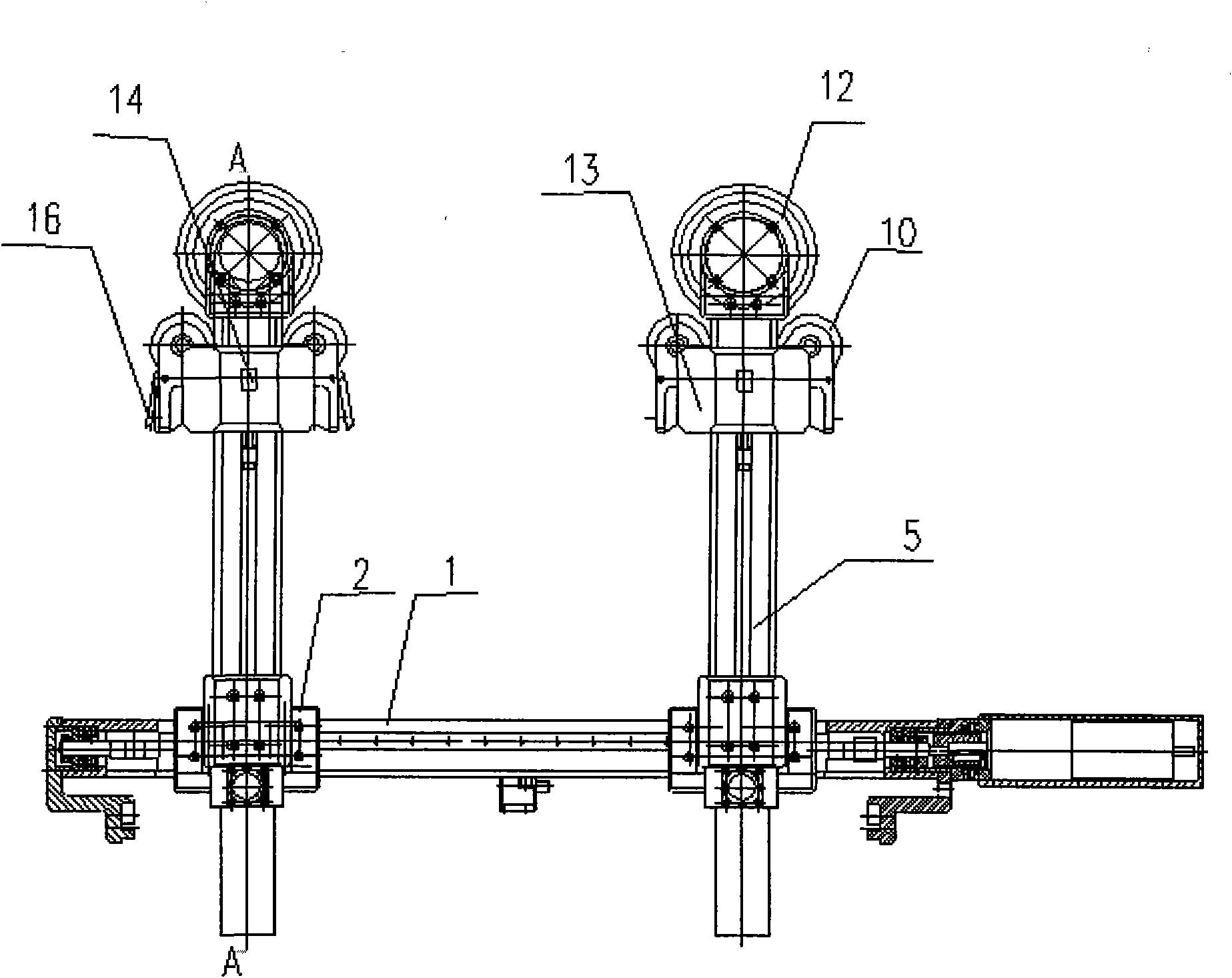

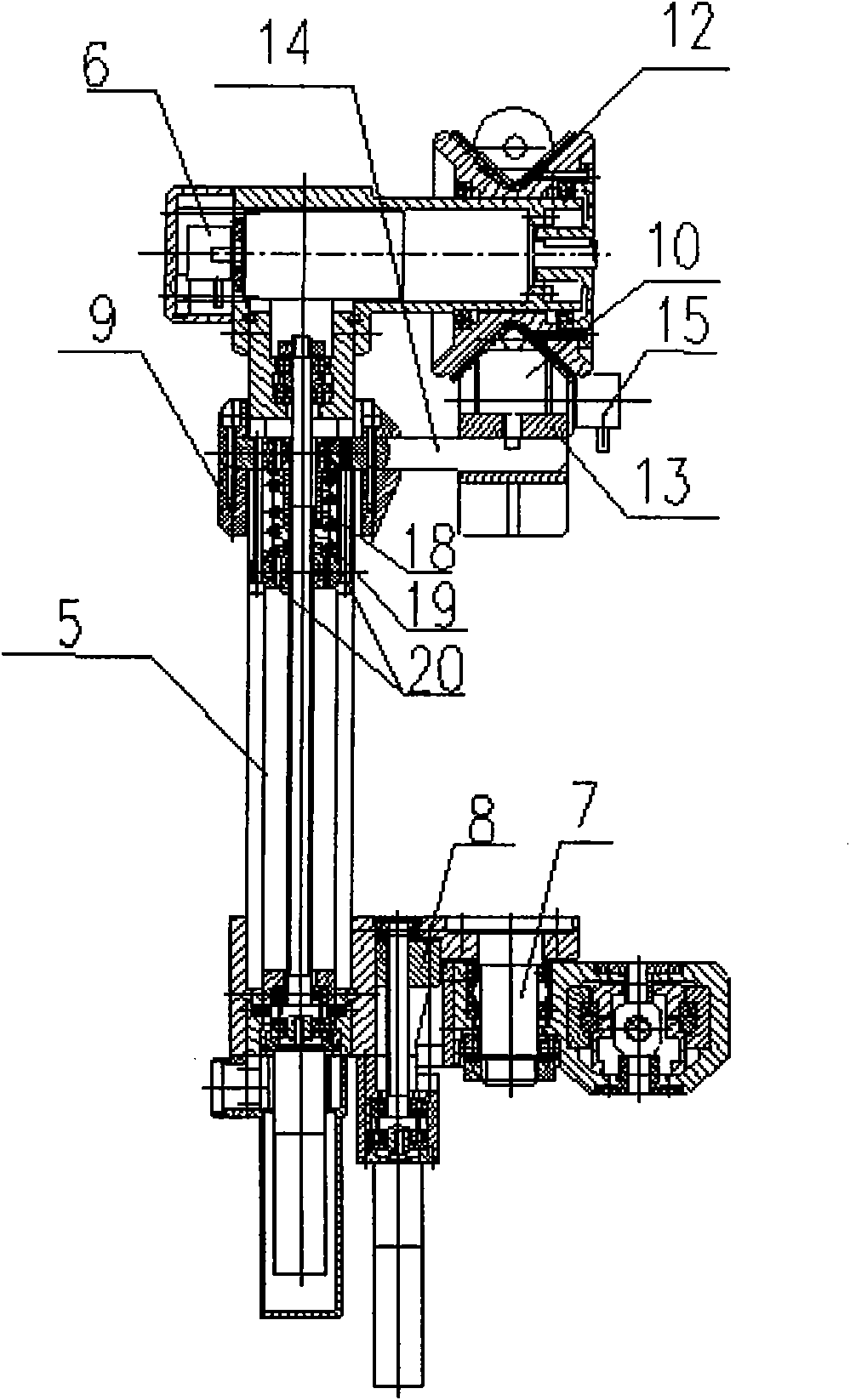

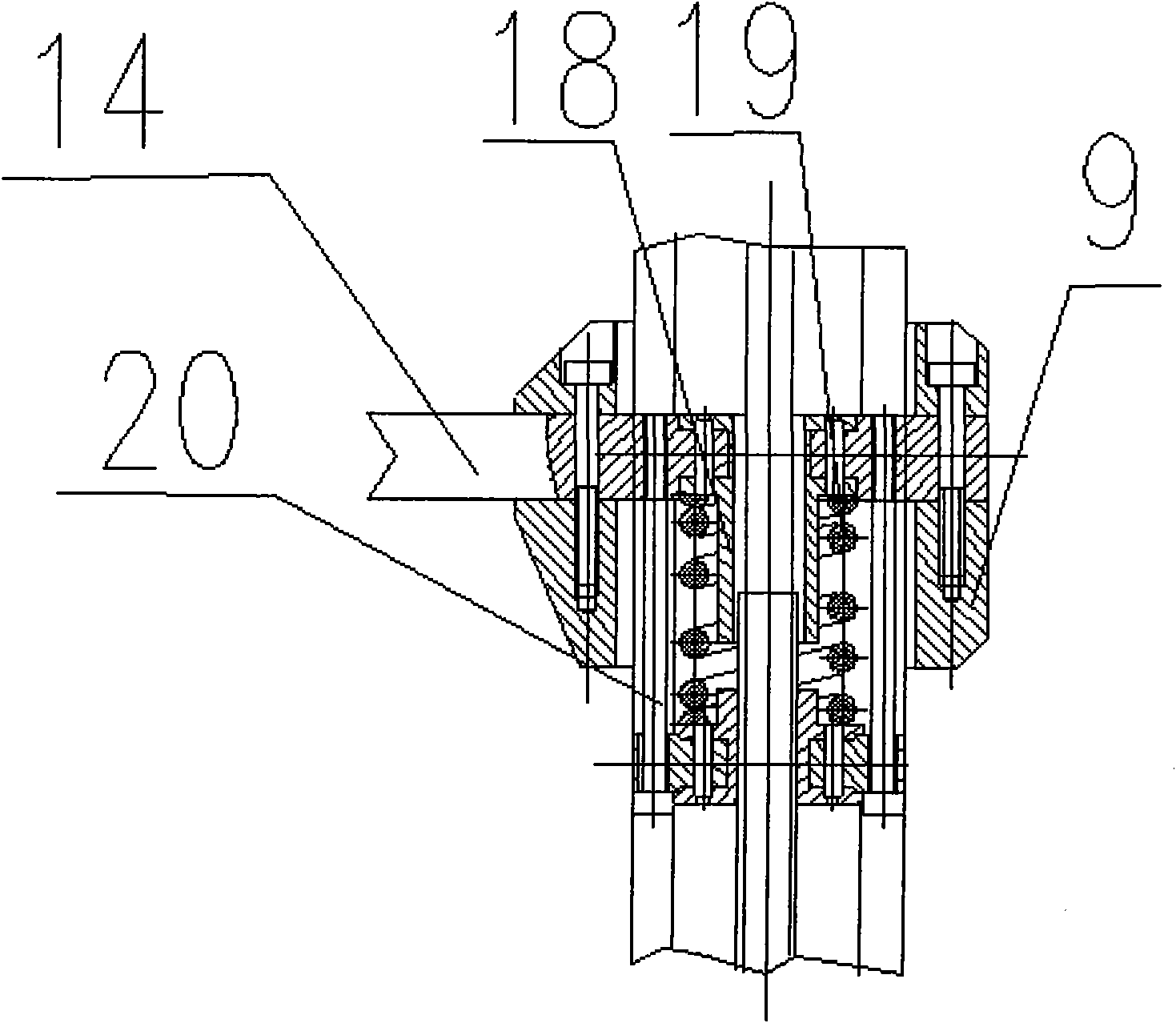

[0029] see Figure 1-9 , a robot for transmission line inspection, which includes a mobile body 1, two body slides 2 that can change the relative distance are arranged on the mobile body, and a positive and negative lead screw is provided inside the mobile body, and the positive and negative lead screw includes There are two sections of positive screw rod and reverse screw rod. Both screw nuts are provided with screw nuts. The screw nuts are fixedly connected with the sliding table of the body. One end of the positive and negative screw rods is equipped with a first motor; The Y-shaped groove 3 that is narrow at the bottom and wide at the top is connected with a rotary mechanism 4 respectively on each body sliding table, and a mechanical arm 5 is fixedly arranged on the rotary mechanism, which can be welded, pinned, or integrated. The mechanical arm is provided with a clamping mechanism and a walking mechanism sequentially from bottom to top, a second lead screw controlled by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com