Disc-type permanent magnet motor rotor

A permanent magnet motor and motor shaft technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems affecting the improvement of motor power density, efficiency and reliability, and improve the utilization of magnetic energy. rate, small air gap, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

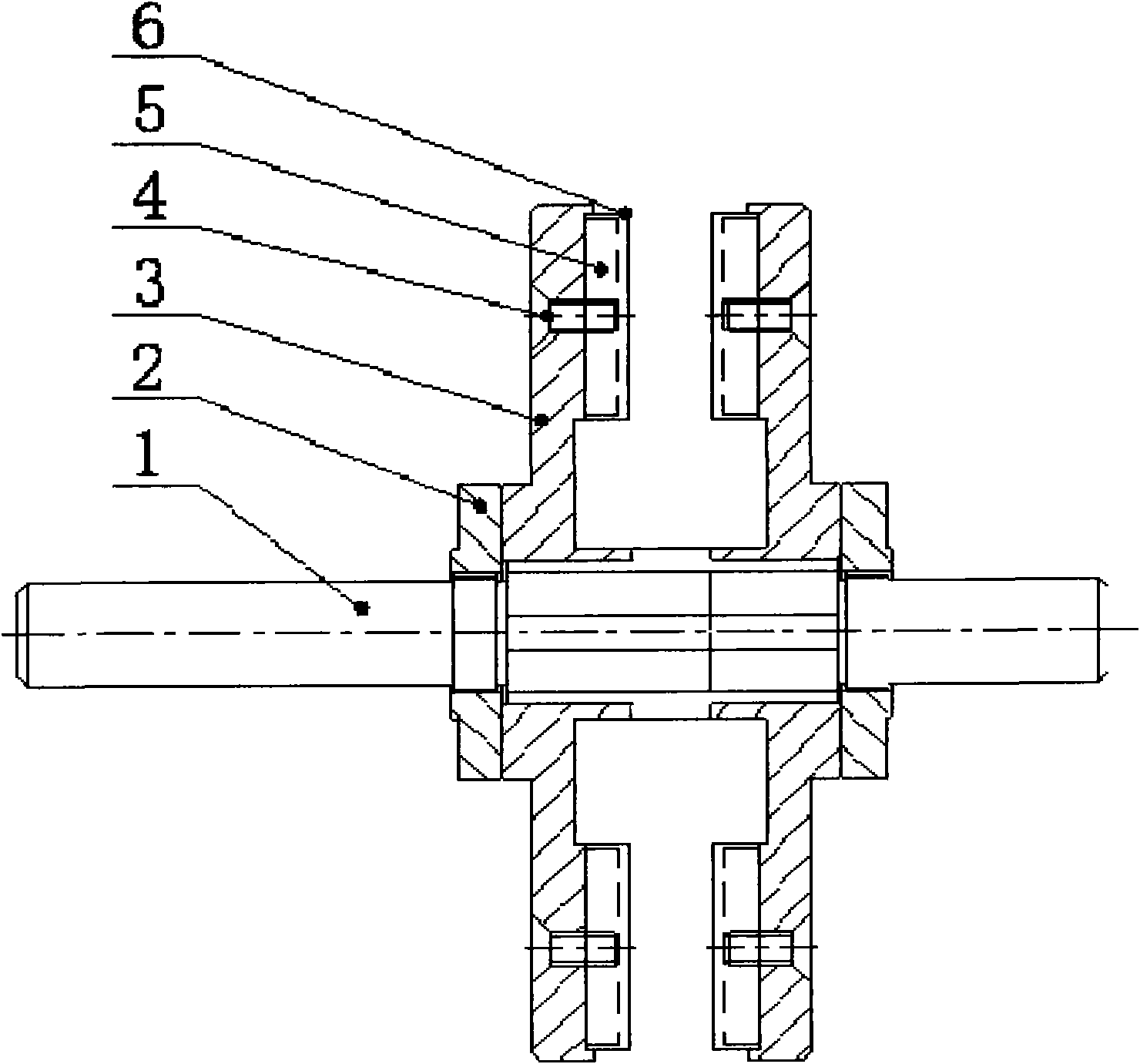

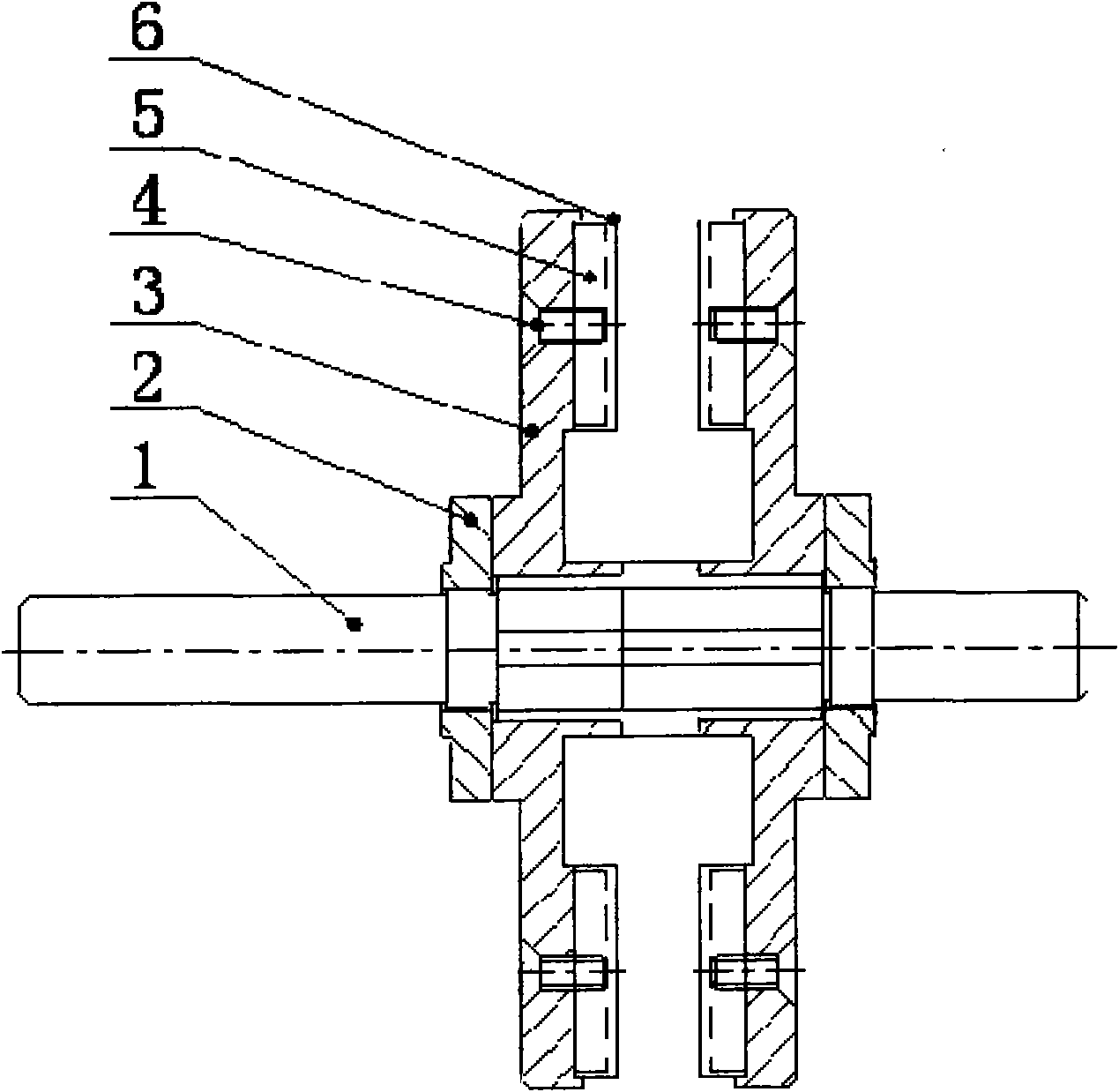

[0020] exist figure 1 In , the embodiment of the disc permanent magnet motor rotor equipped with two rotor disk assemblies is given. The motor shaft 1 is equipped with a nut 2, a magnetic blocking plate 3, a screw 4, a pressure block 5 and a permanent magnet 6; the magnetic blocking plate 3 is connected with the motor shaft 1 through a spline and fixed by nut 2; the permanent magnet 6 is fixed on the magnetic blocking plate 3 by the pressure block 5 and the screw 4; the rotor disk assembly can be one, two or more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com