Centrifugal high-gradient magnetic method

A magnetic separation method and high gradient technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of reduced concentrate quality, difficult to meet the requirements of mineral processing industry production, and small processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

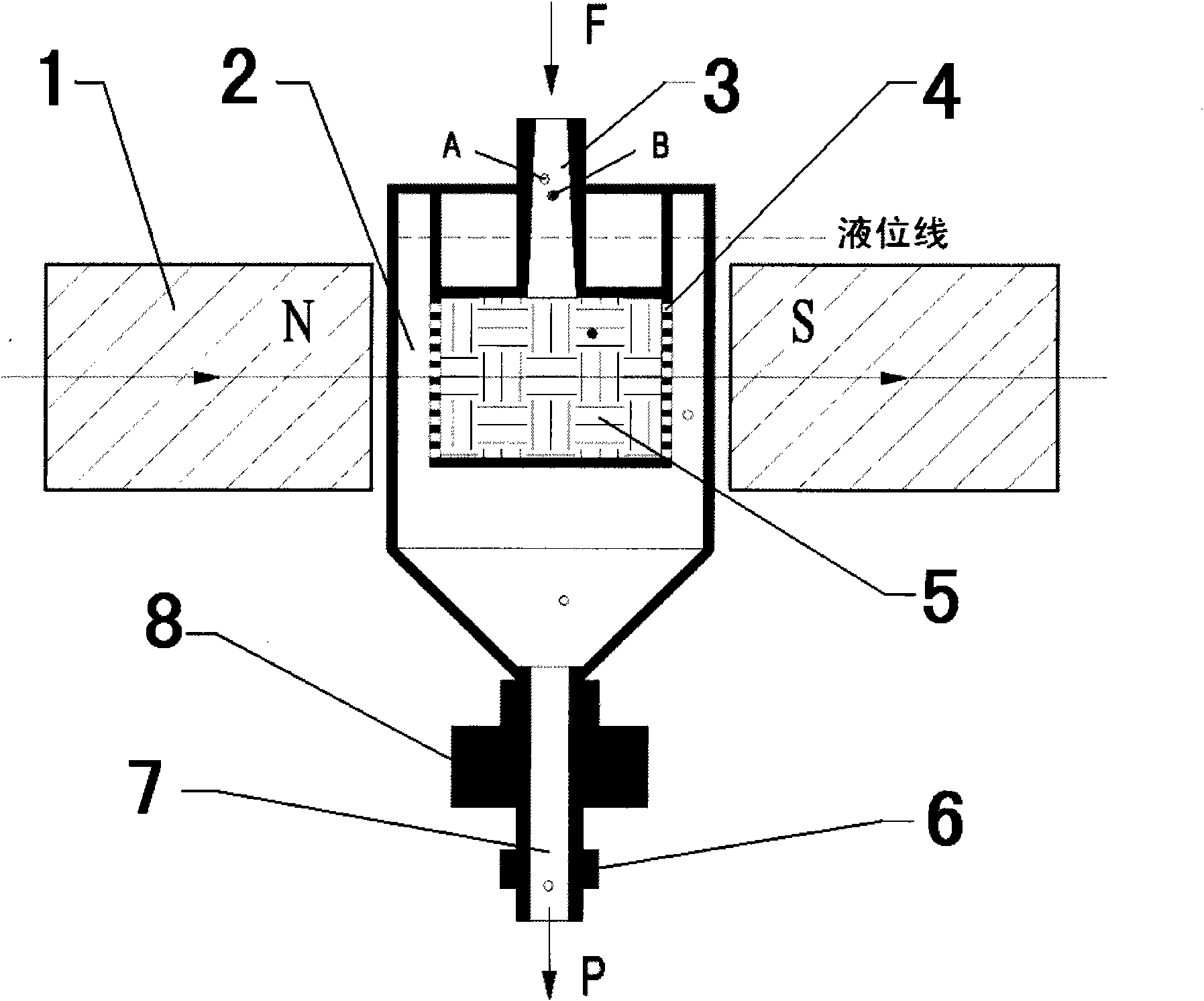

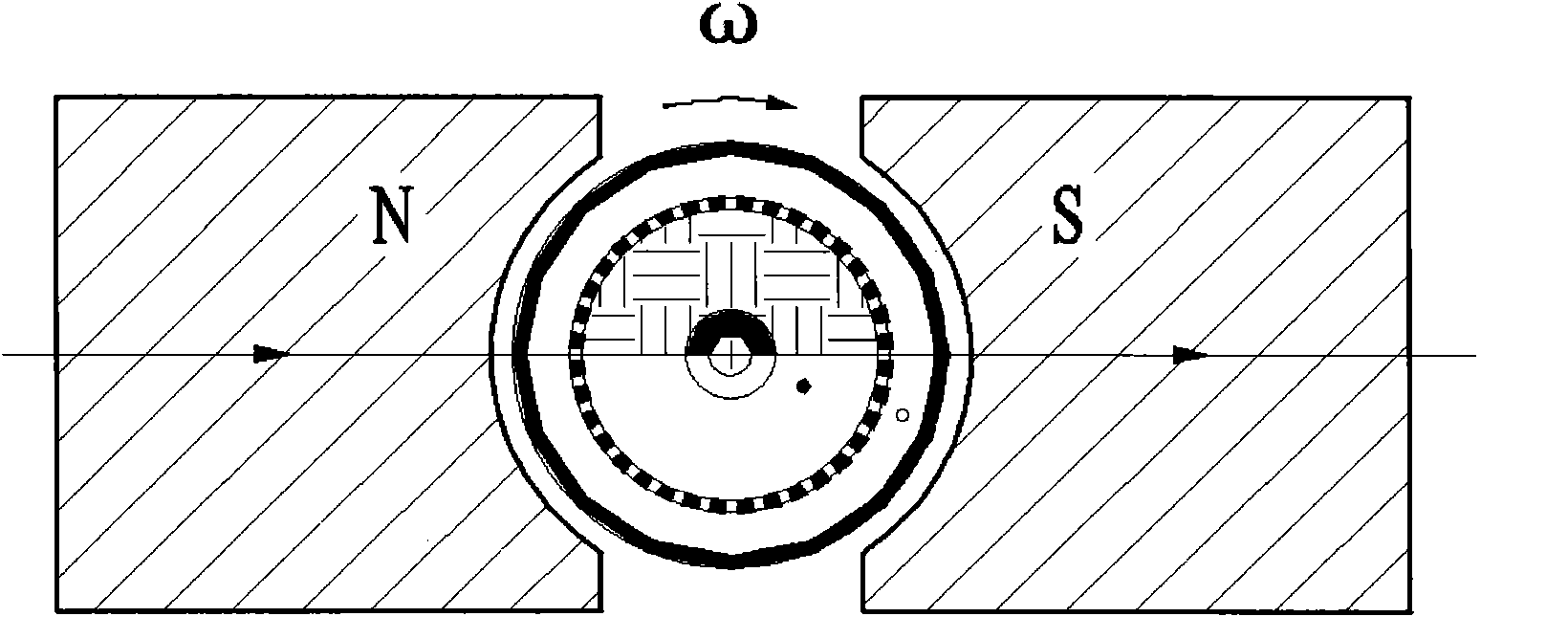

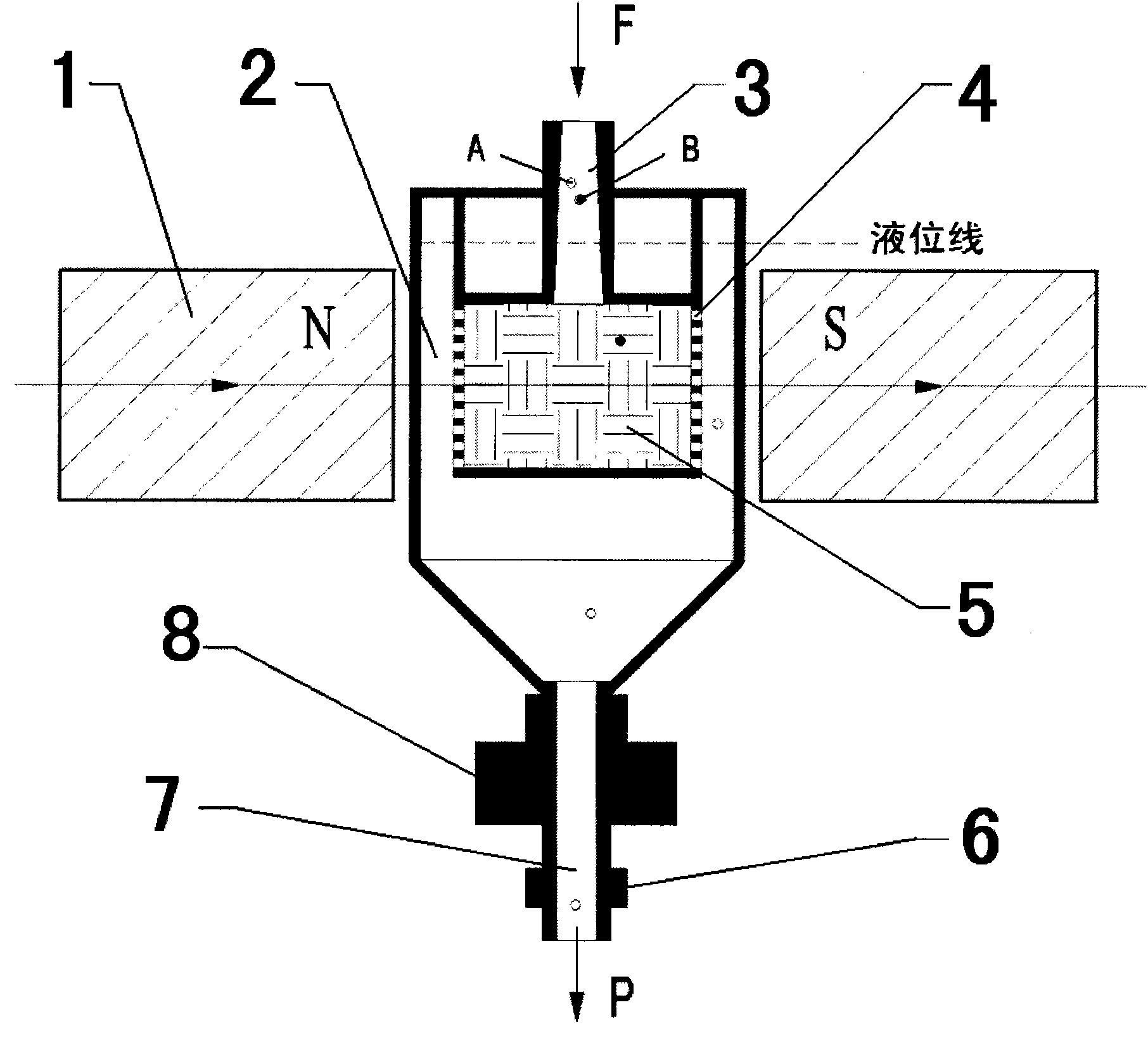

[0013] like figure 1 and 2 As shown, the ore pulp self-supply cone pipe 3 enters the sorting cylinder 2 and the magnetic medium cylinder 4, and there are holes on the cylinder wall of the magnetic medium cylinder 4 to communicate with the inner cavity of the sorting cylinder 2; The mine valve 6 keeps the ore pulp at a certain liquid level in the sorting cylinder 2 and the magnetic medium cylinder 4 . The transmission device 8 drives the entire sorting device (including the sorting cylinder 2, the magnetic medium cylinder 4, the magnetic medium 5 and the ore discharge valve 6, etc.) The high gradient magnetic field generated on the surface of the medium 5 forms a new comprehensive force field. The rotation axis of the sorting drum 2 is perpendicular to the magnetic field of the magnetic system 1 . The ore particles in the magnetic medium 5 are sorted under the comprehensive action of the high gradient magnetic field and the centrifugal force field. The magnetic force receive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com