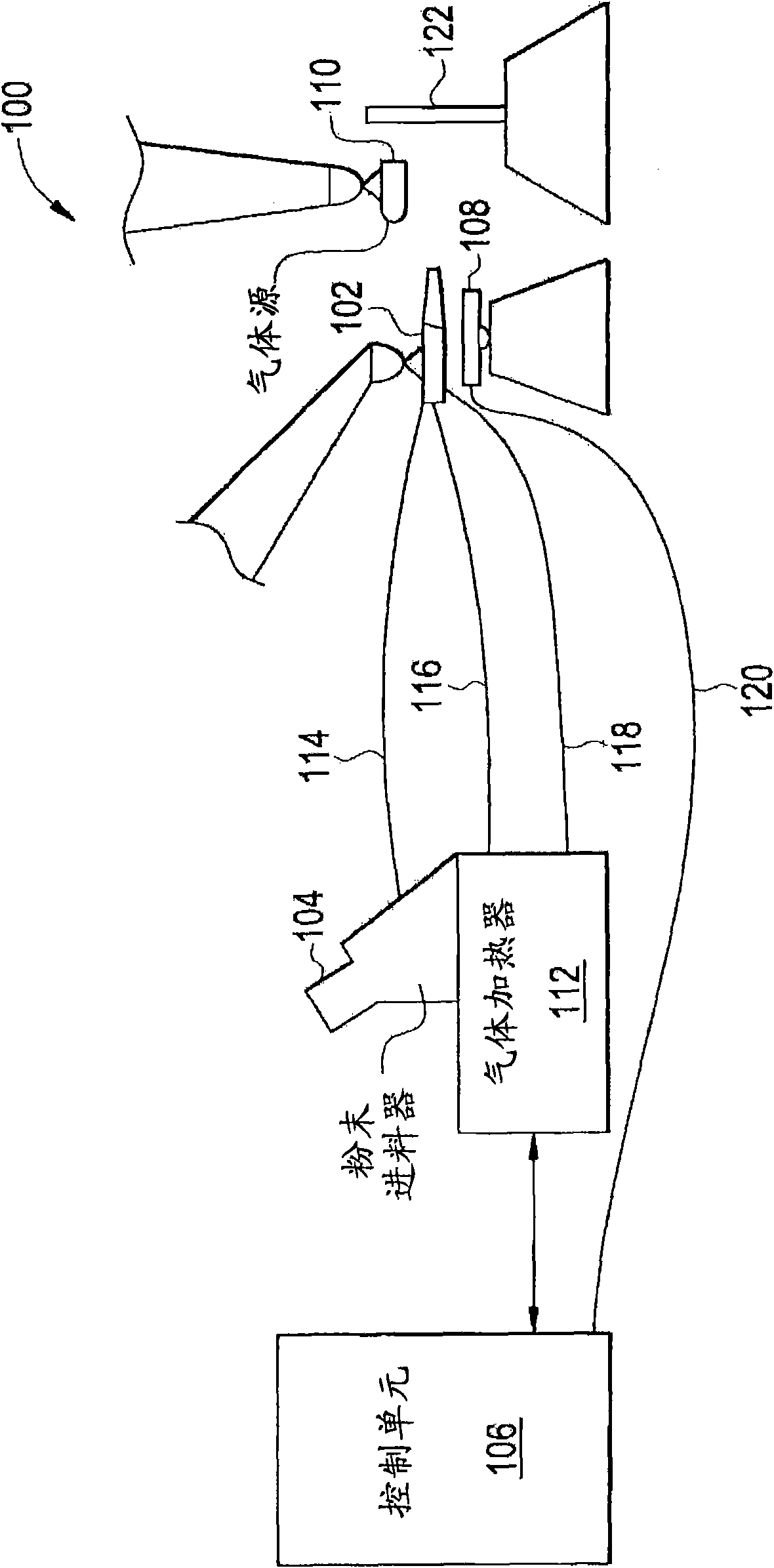

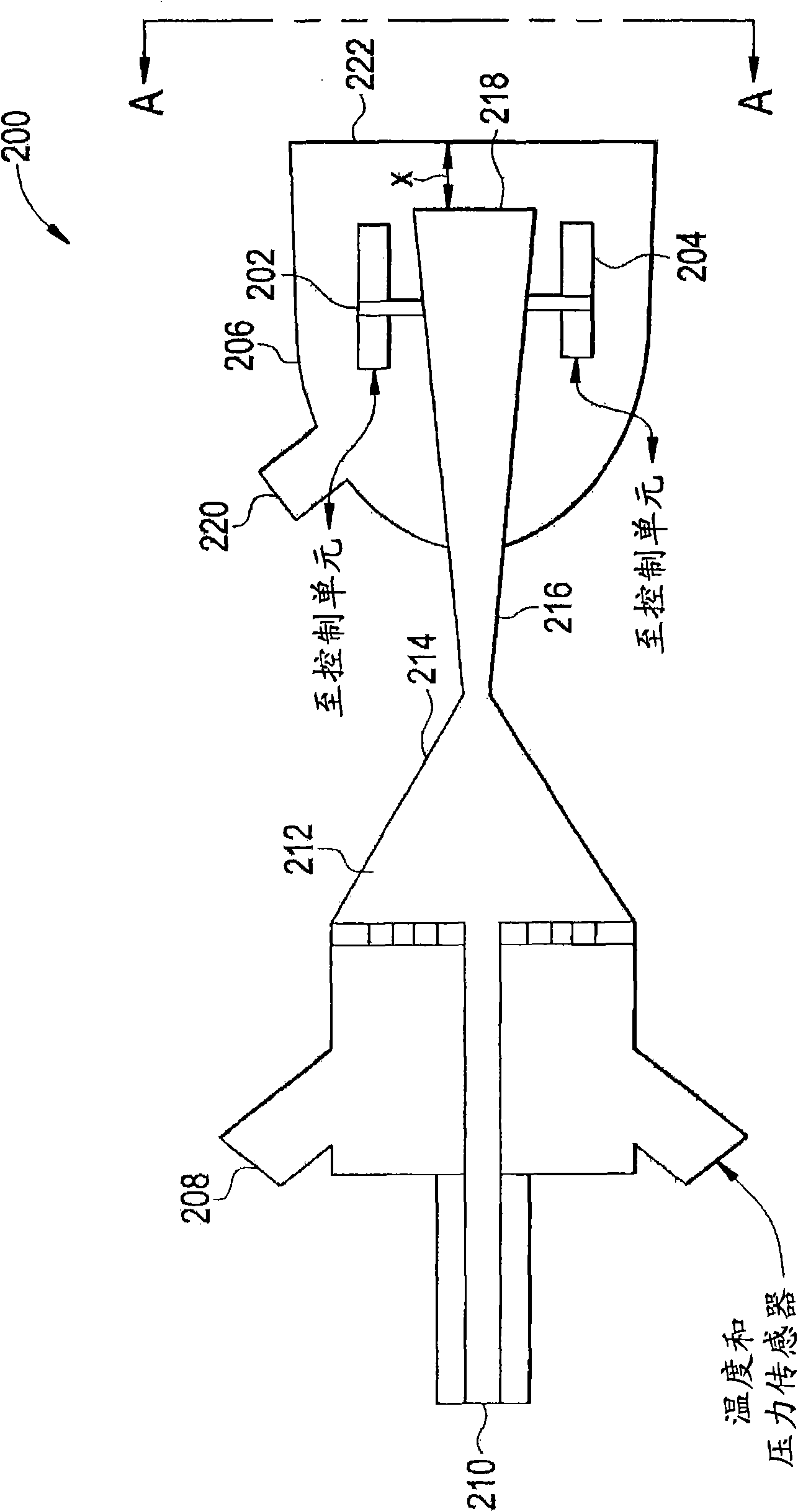

Apparatus, systems, and methods involving cold spray coating

A technology of cold spraying and nozzles, which is applied in the direction of spraying devices, devices for coating liquid on surfaces, liquid spraying devices, etc., and can solve problems such as increasing the complexity and duration of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

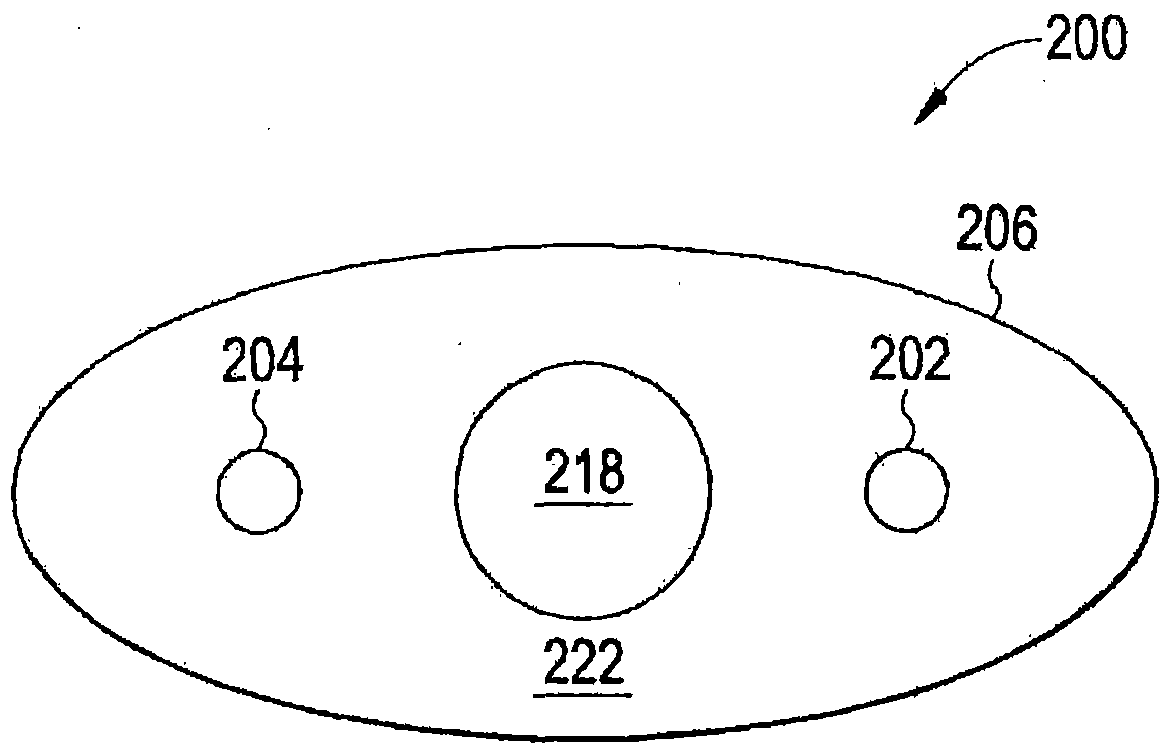

Embodiment Construction

[0017] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of various embodiments. It will be understood, however, by those skilled in the art that these embodiments may be practiced without these specific details, that the embodiments are not limited to those depicted, and that the embodiments may be practiced in a wide variety of alternative embodiments. In other instances, well-known methods, procedures, and components have not been described in detail.

[0018] Additionally, various operations may be described as multiple discrete steps performed in a manner that is helpful in understanding the embodiments. However, the order of description should not be read as to imply that these operations need to be performed in the order they are presented, or that they are even order dependent. Additionally, repeated use of the phrase "in one embodiment" does not necessarily refer to the same embodiment, but cou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com