Thickness sorting machine of wood chips

A sorting machine and wood chip technology, which is applied in the directions of classification, solid separation, chemical instruments and methods, etc., can solve the problems of inability to separate thick wood chips, low utilization rate of wood resources, and increased consumption cost, and achieves good sorting effect. , no clogging and vibration, low maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The content of the present invention will be further illustrated below in conjunction with the accompanying drawings and specific examples, but these embodiments do not limit the protection scope of the present invention.

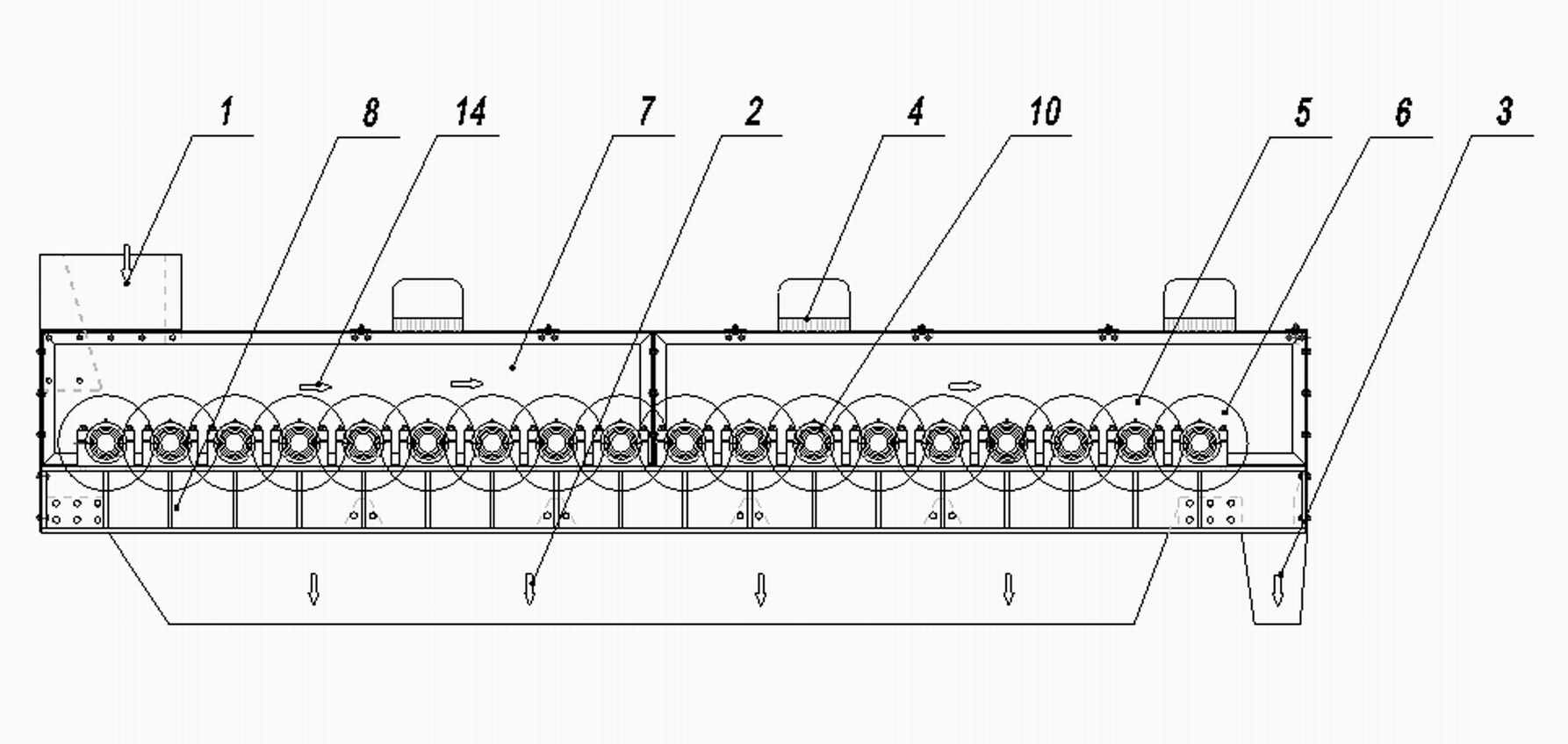

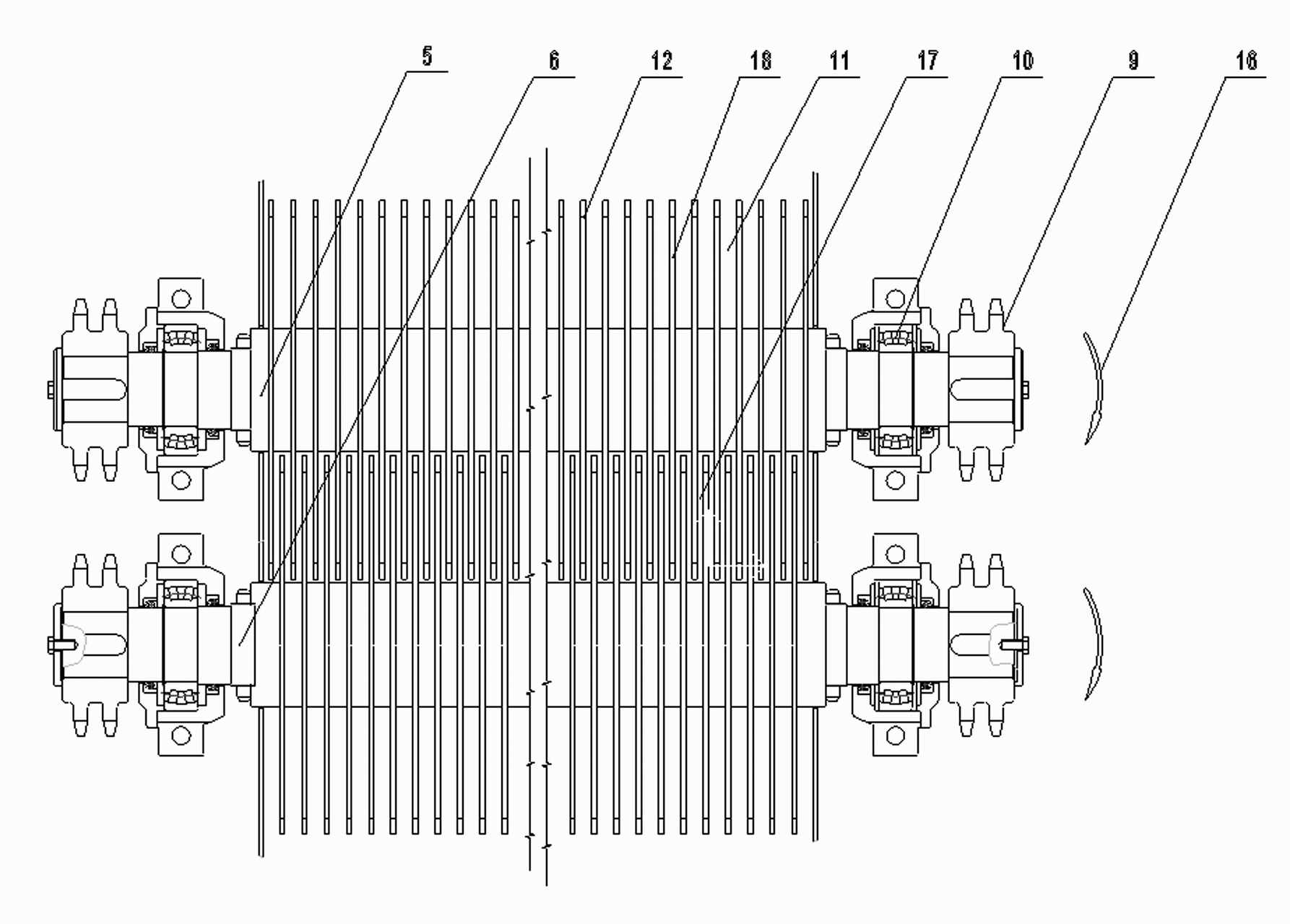

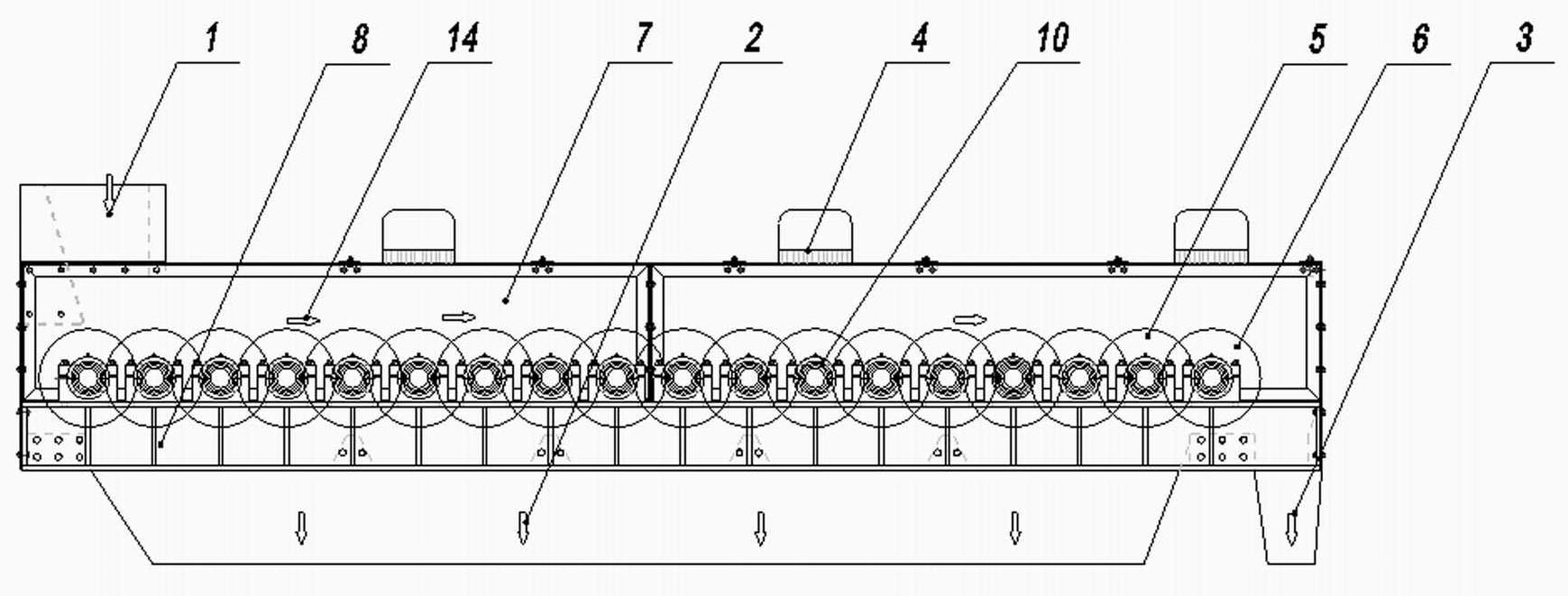

[0016] Such as figure 1 , 2 As shown, the present invention has a body 7 and a roller, the body 7 is a fixed box structure connected to the foundation, and 9 rollers A and 9 rollers B are alternately arranged on the body, and the rollers A and B are Assembled parallel to each other, the roller shaft is a structure with long roller grooves 11 evenly distributed in the axial direction and triangular roller teeth 12 distributed in the radial direction. The roller groove 11 is composed of a series of toothed discs 18, and the discs Spacers are used to separate the discs from each other. The present invention is provided with 3 transmission boxes, and each transmission box drives 6 roller shafts to rotate through transmission wheels.

[0017] figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com