Double-sheet spot welding hot stamping method and welding structure thereof

A technology of hot stamping and blanks, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as complex procedures, high production costs, and impact on automobile quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

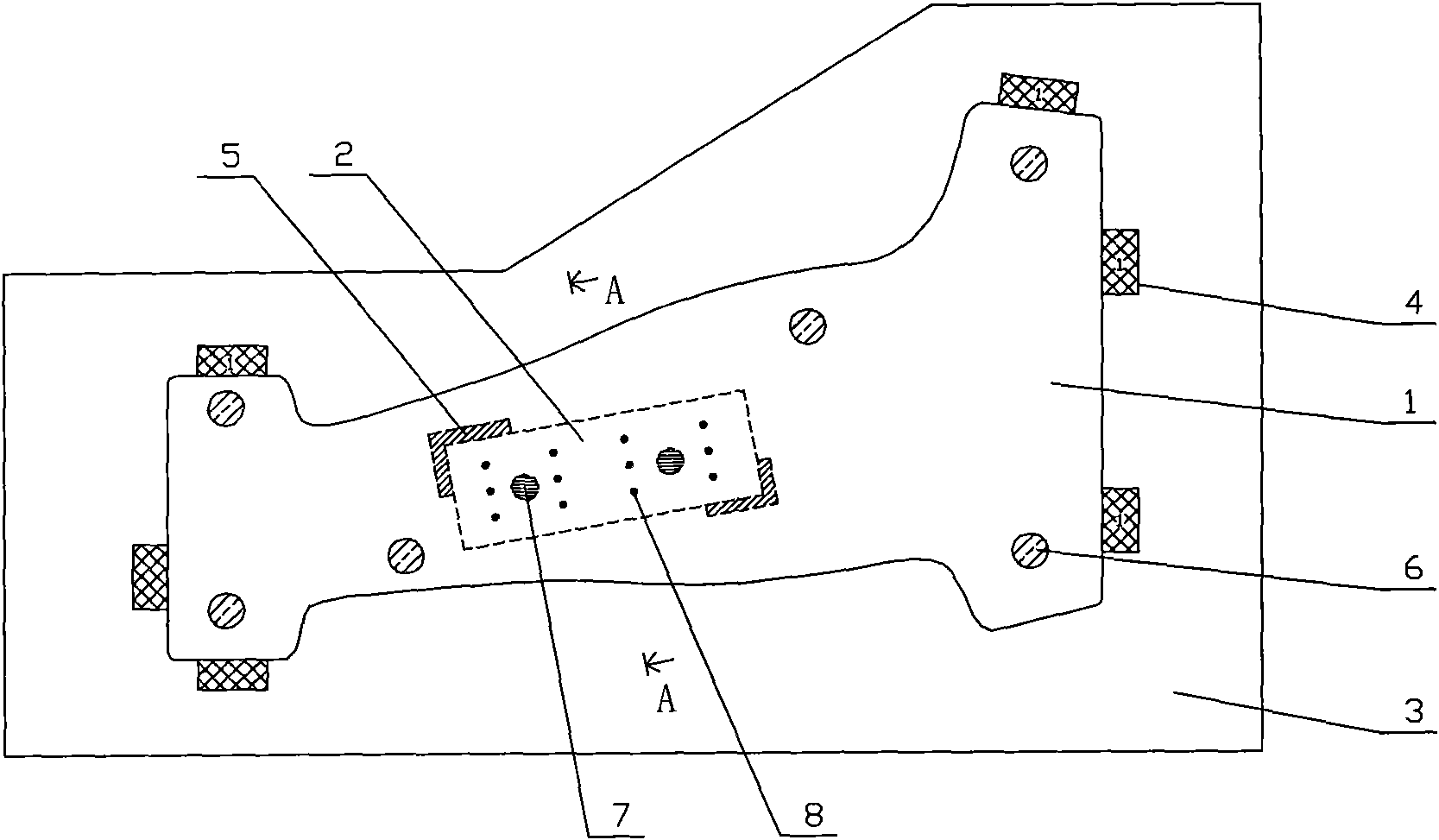

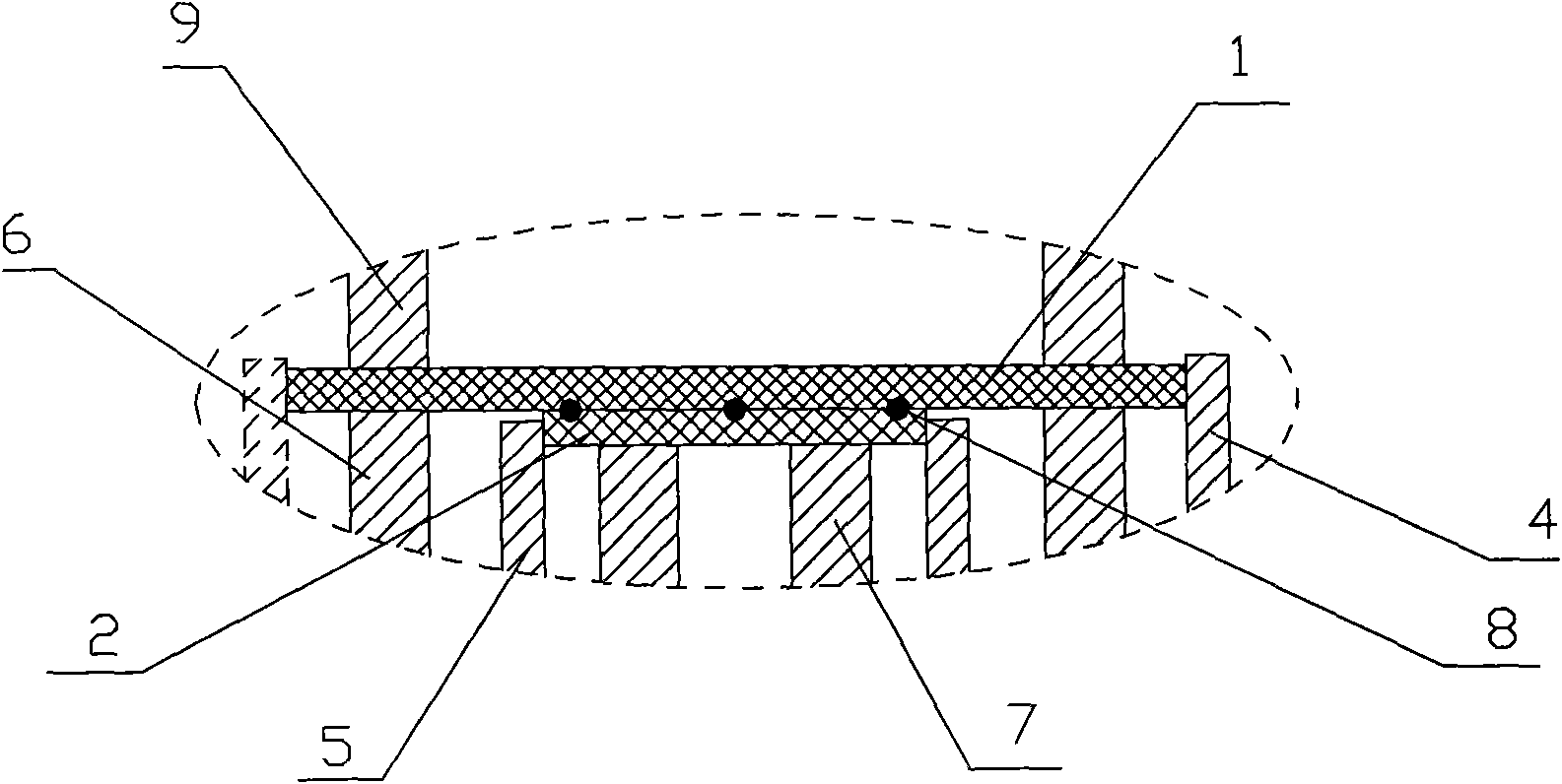

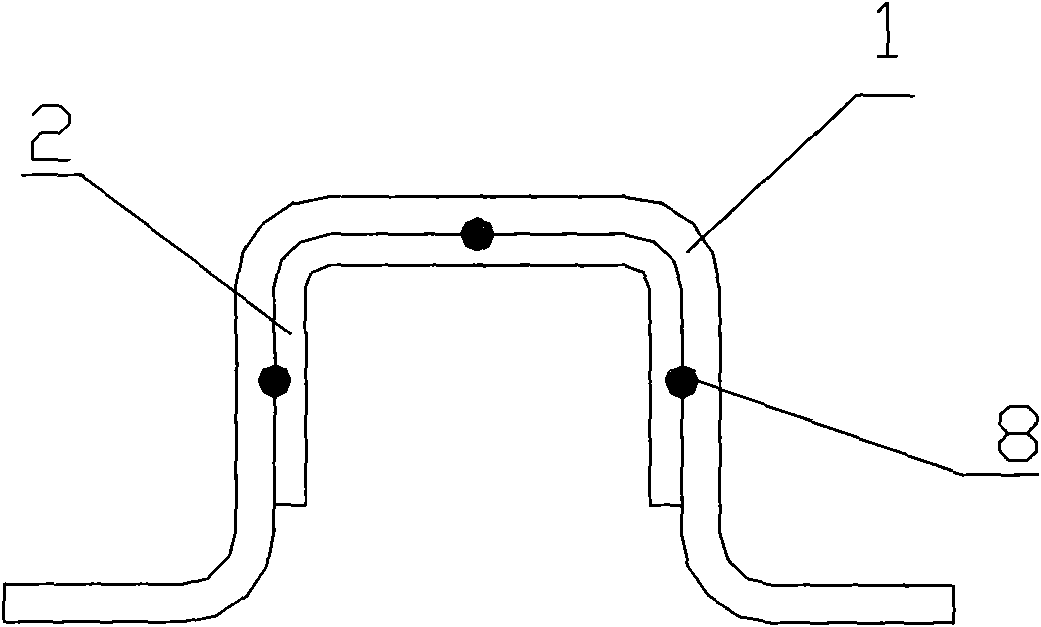

[0018] The double sheet spot welding hot stamping method includes the following steps: first, two sheets of the same material are welded together, and the welded structure is as follows: figure 1 , 2 As shown, it includes a small blank 2 and a large blank 1. The external contour shape of the two blanks is calculated according to the state of the part after molding, and is realized by blanking die or laser cutting in advance. The two blanks The sheets are made of the same grade of high-strength steel. The welding structure also includes a workbench 3 on which several first support columns 7 and several second support columns 6 are arranged. The small piece 2 is placed on the first support column 7, and several first positioning blocks 5 are arranged around the small piece 2, and the first positioning blocks 5 block the small piece 2, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com